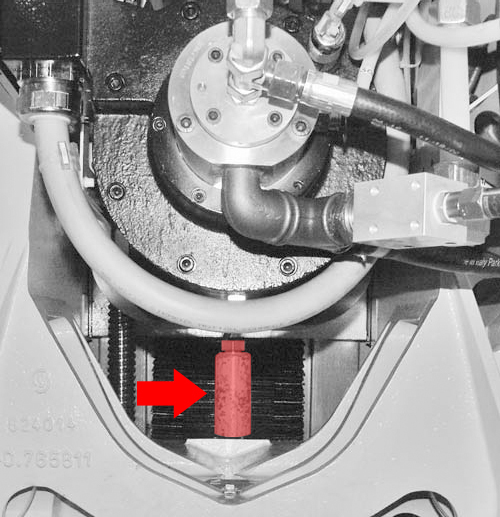

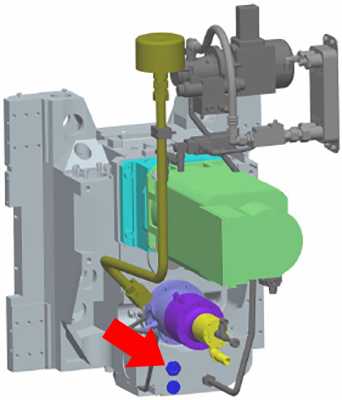

Check Oil Level in the Gear LubricationInterval 500 Hours Operating time Component Guide slides of the machining unit Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. If you enter the machine without securing the machining unit, do not linger around the danger zone! Check for Leaks and Top up OilConsumable Lubrication oil CLP 46 acc. to DIN 51517, part 3 (ISO-L-CKC 46 acc. to ISO 6743, part 6) Purity class ISO 4406-18/16/13 Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. Can with narrow neck or funnel,Fine filter, ladder Procedure Machining unit protected from falling by supports. Check machining unit for escaping oil. Possible leakages:

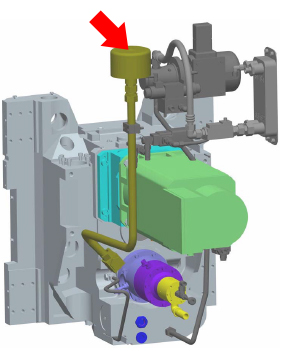

You can replace defective hose lines or mounting parts yourself. Leakages in the guide blocks (cover, unclamp device, gear change mechanism, motor flange) indicate defective sealing rings or bushes inside the machining unit. Have this damage repaired by customer services. Do not operate machine with damaged machining unit! Top up oilProcedure Remove the ventilation filter. Fill with oil through oil filler tube up to the center of the inspection glass. Mount ventilation filter. Remove support from the machining unit. Before closing the maintenance safety door, ensure that nobody is behind the guard panels. Close maintenance area safety door. |