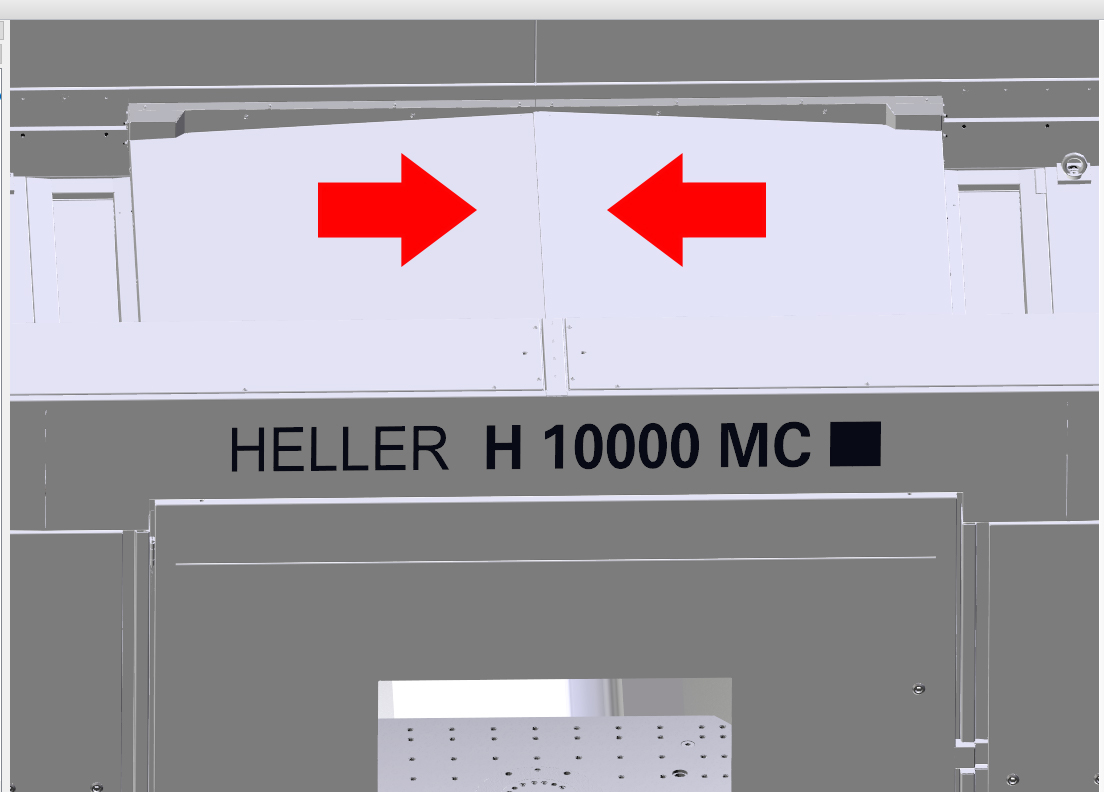

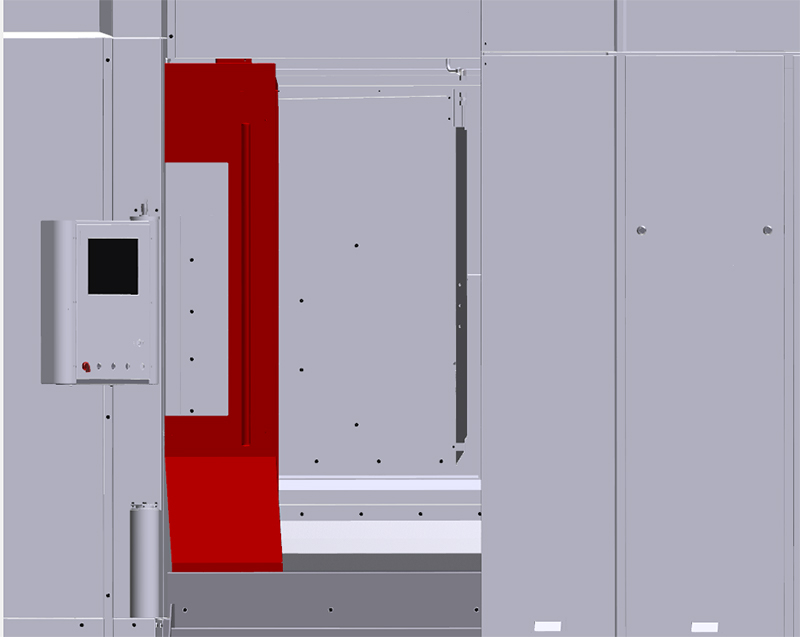

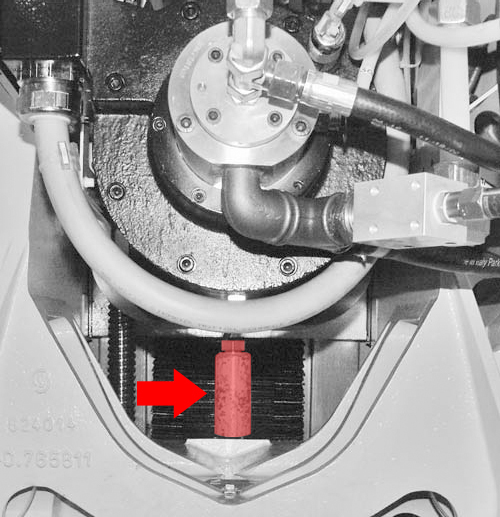

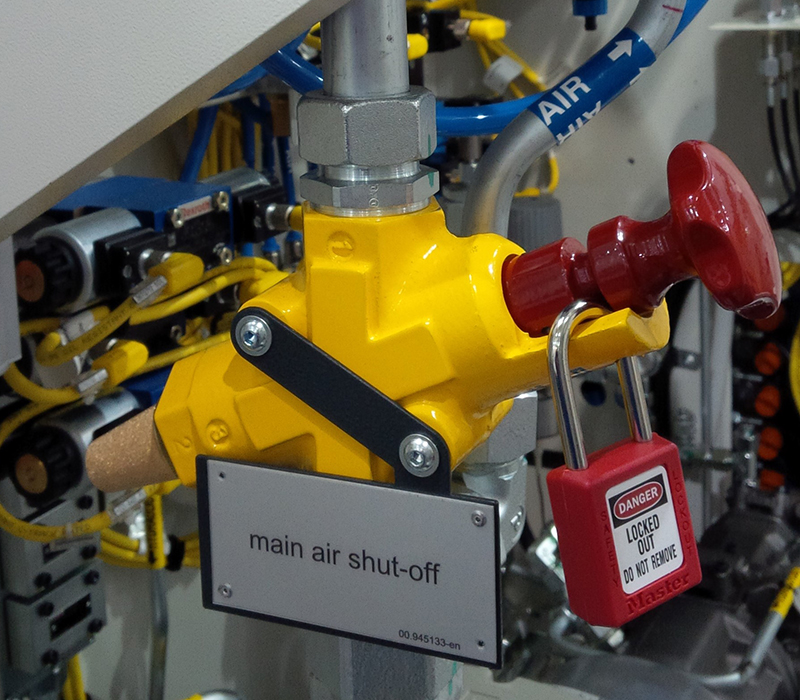

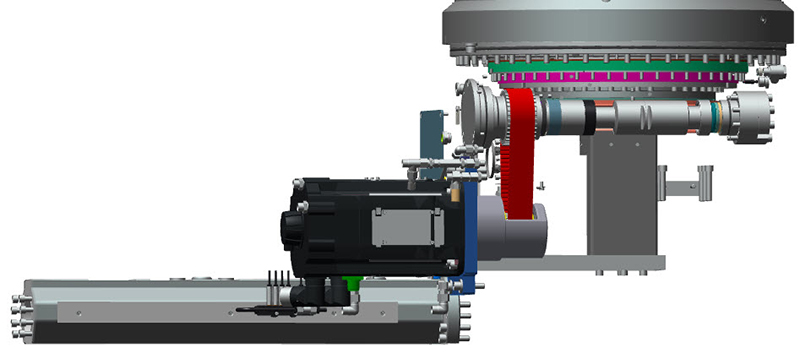

Replace Timing Belt of the Rotary Table DriveInterval 10000 Hours Operating time Component Rotary feed table The timing belt must be replaced at regular intervals in order to avoid fatigue break. This activity must only be carried out by specially trained personnel. Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Exercise caution when working inside the machine with the machining unit not secured! Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Before closing the safety doors, ensure that nobody is behind the guard panels. Close and lock the work area safety door and the maintenance area safety door. Step 12: |