Reference Point of the Z axis

Reference Files

Tools Required

Torque Chart

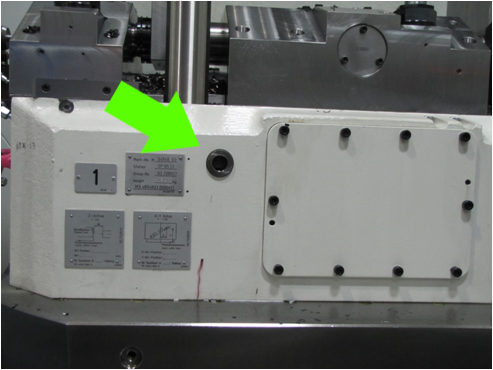

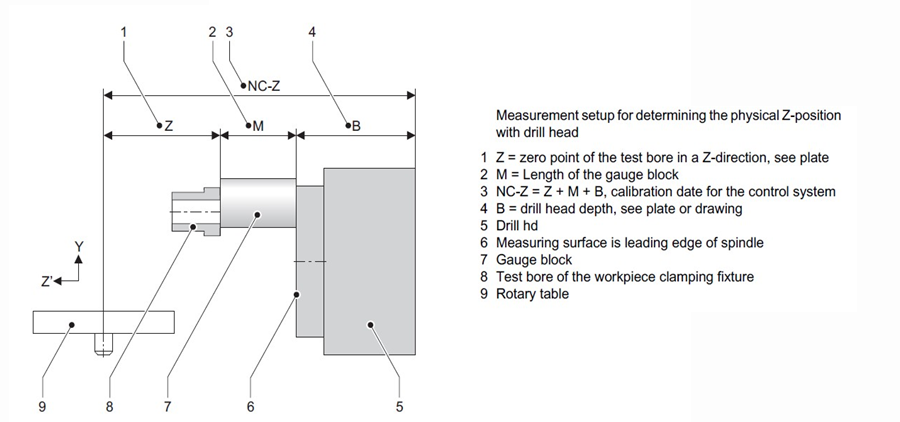

Step 1:The following procedure is taken from a Heller MC20 machine, although the H series machine uses an HSK 100, the same steps apply. Step 2:Z axis reference point using bushing on fixtureTools needed: Step 1:If access to the blank pallet is not possible due to the fixture being installed, the correct axis position can be determined using the fixture bushing. Each machine has a bushing on one face of the fixture that is calculated using the machine axes after machine installation and runoff has been completed. In addition, there is a plate with the axes positions of this bushing. The Z axis position is determined by placing the gage block with minimal resistance between the spindle pads and bushing face. The actual Z axis position must then be calculated. Step 2: |

|||||||||||||||||||||||||||||||||||||||