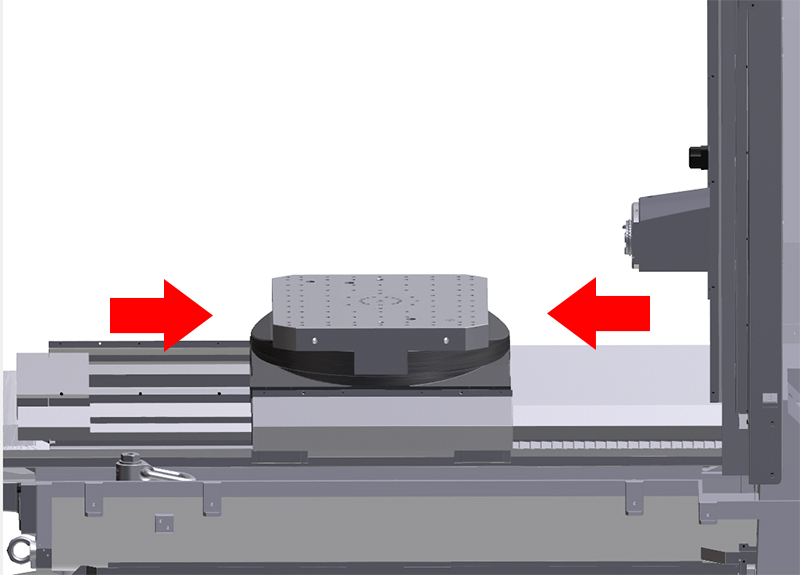

Cleaning and Checking Fill Level SensorInterval 1500 Hours Operating time Component Fill level sensor, mounted to the chip conveyor For manufacturer's documentation on the fill level sensor, see Subsuppliers' Information (ZI) from "Knoll", documents from IFM. CleaningThe fill level sensor is removed from the container for maintenance and cleaning work. During reinstallation, the fill level sensor must be mounted at the exact same position and installation height as before. Prior to removal, fix the set installation height with the enclosed marking clamp. Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Exercise extreme caution when working in the maintenance area with unsecured machining unit! Avoid working below the machining unit! Step 1:Step 2:The machining unit is positioned so that you can work safely on the chip conveyor:

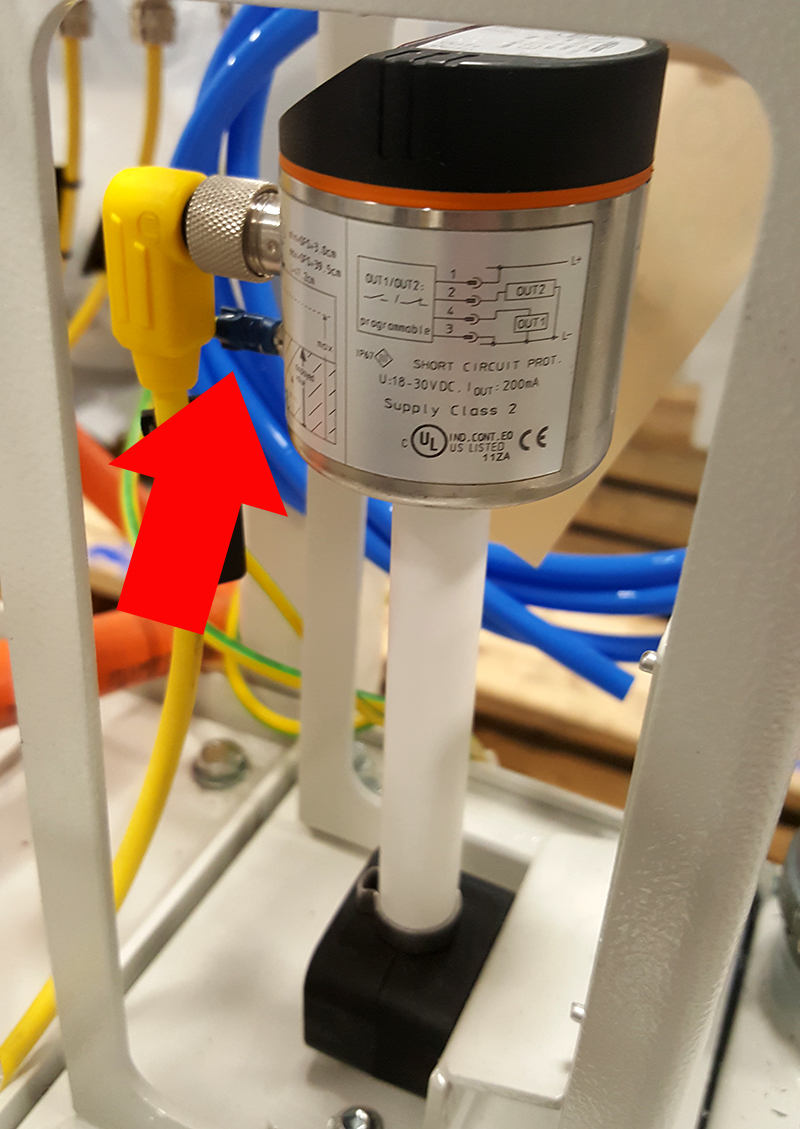

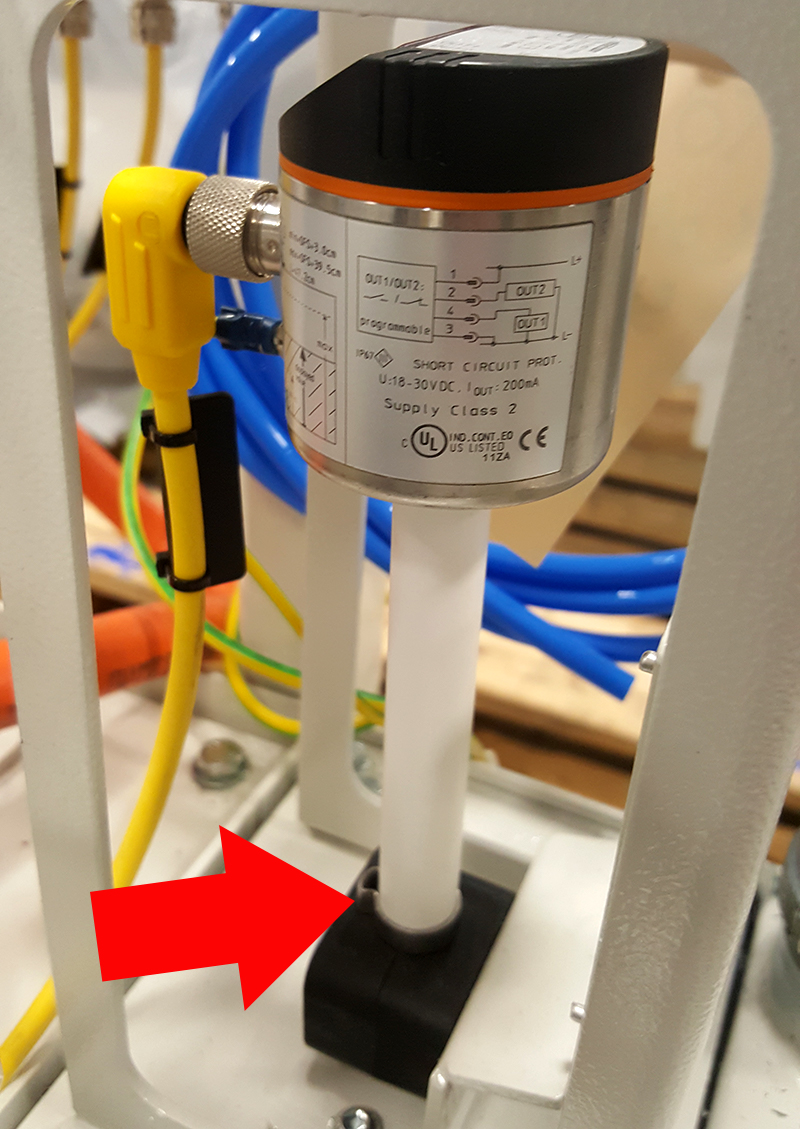

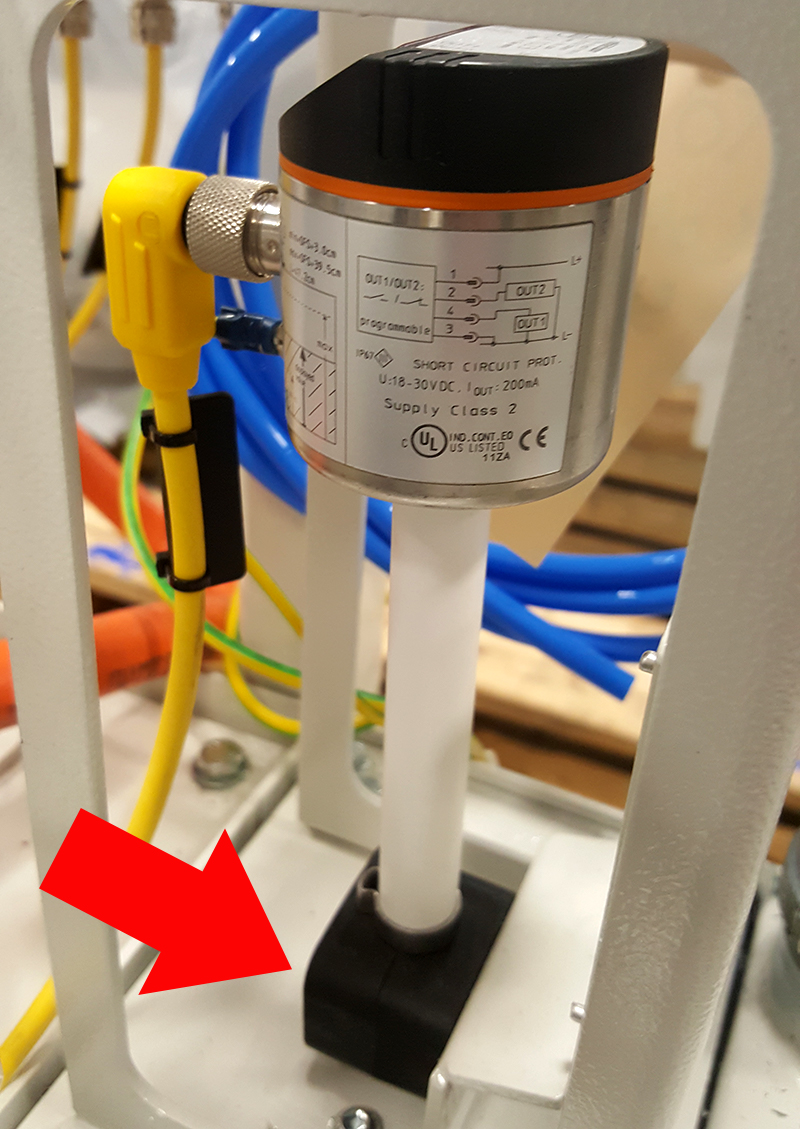

Step 3:Step 4:Step 5:Step 6:Fix the marking clamp to the sensor rod of the fill level sensor using the pipe clamp. Installation position is marked. Step 7:Loosen the screws on the pipe clamp of the fill level sensor. Take the fill level sensor from the housing. Step 8:Check overflow safety mechanismProcedure Test the overflow safety mechanism in accordance with the installation instructions from "Knoll", documents from IFM. Prepare machine for operationStep 1:Insert fill level sensor into the housing until the marking clamp is in contact with the pipe clamp. Step 2:Step 3:Step 4:Before closing the maintenance safety door, ensure that nobody is behind the guard panels. Close and lock maintenance area safety door. |