Cleaning the MachineInterval 1 Year(s) Real time Reduce this interval depending on the contamination of the machine. Component Machine with all units and fittings Recommended cleaning agents:

The cleaning agent must have the following properties:

Other aids:

The following are not permissible:

Cleaning agents may contaminate the cooling lubricant. Take the following precautions:

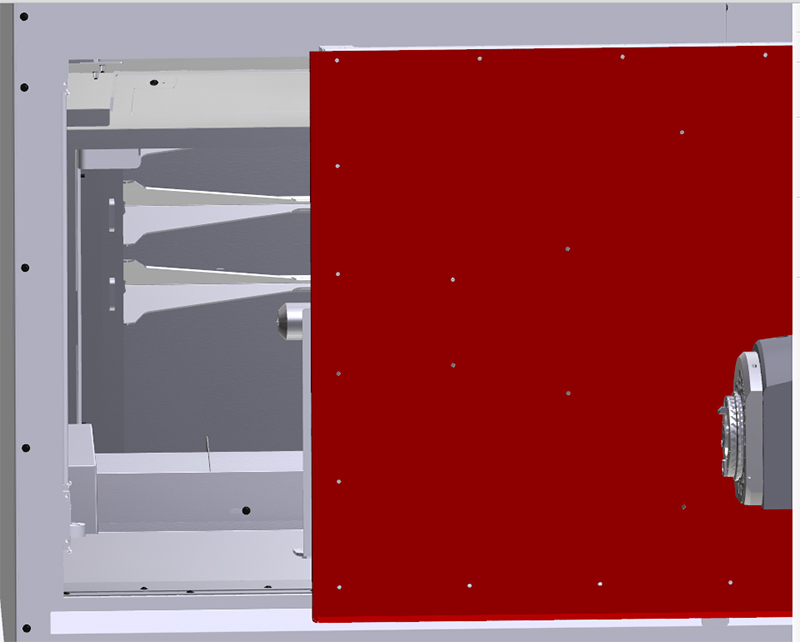

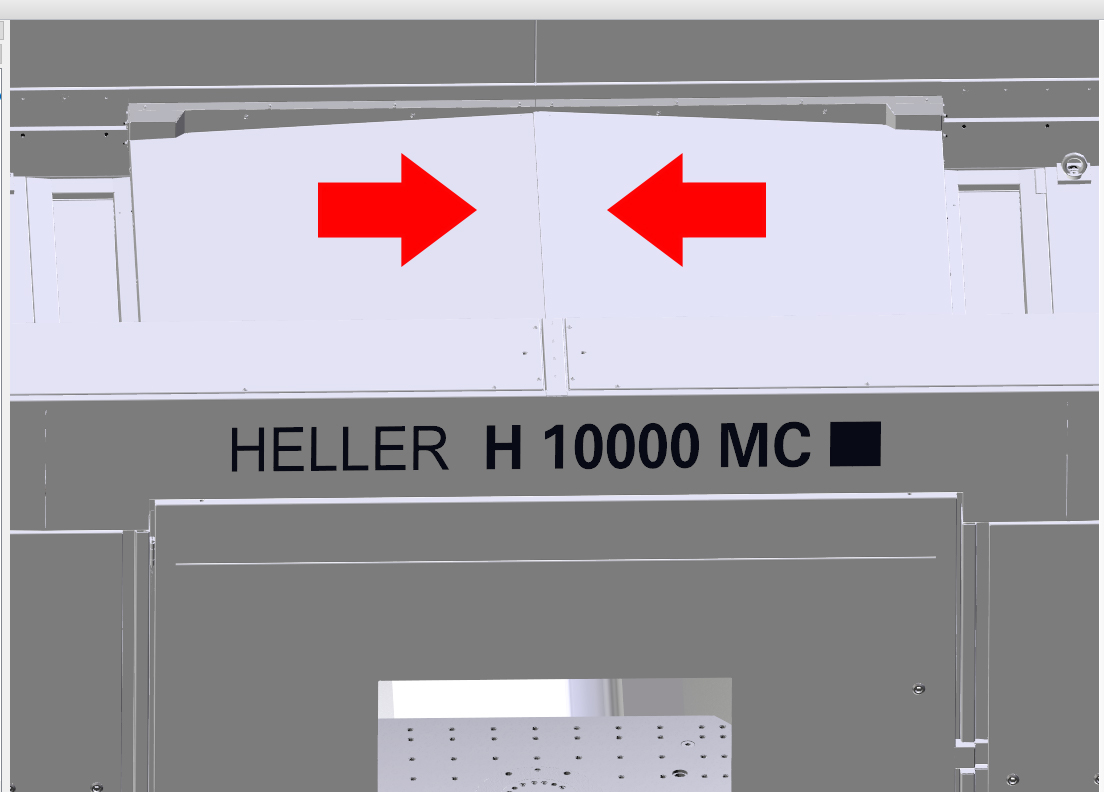

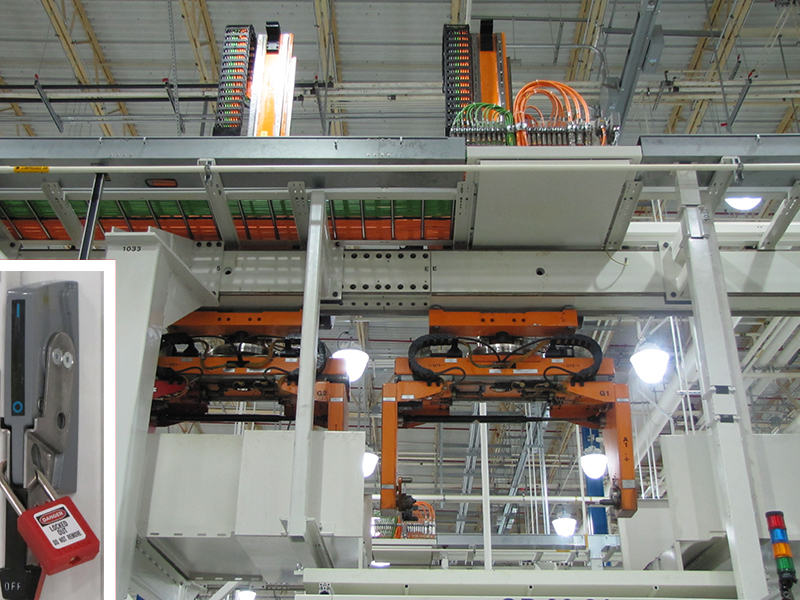

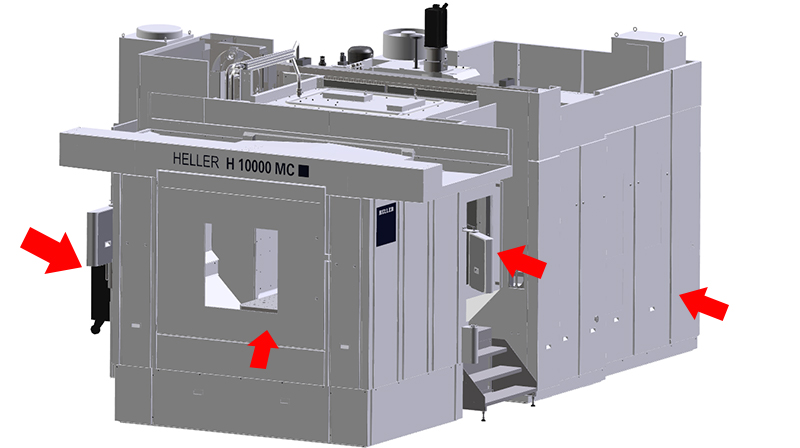

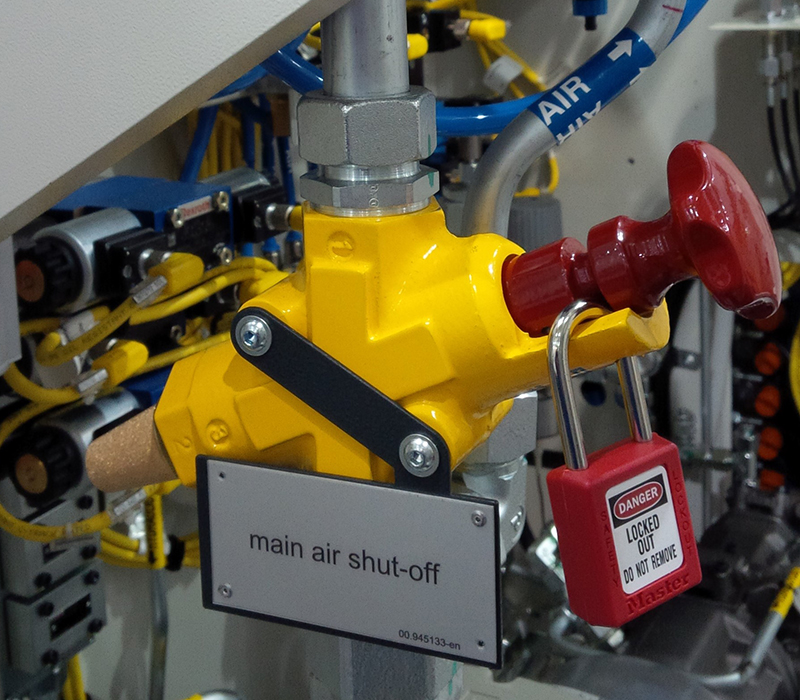

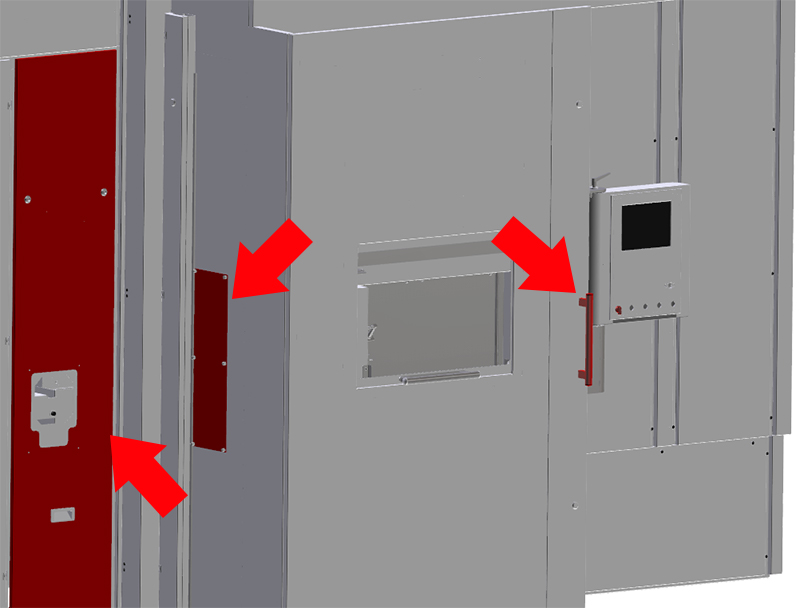

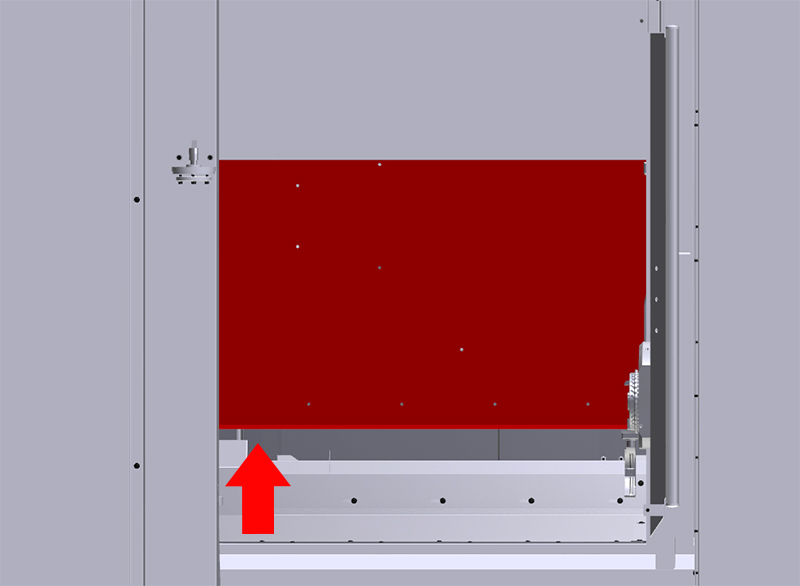

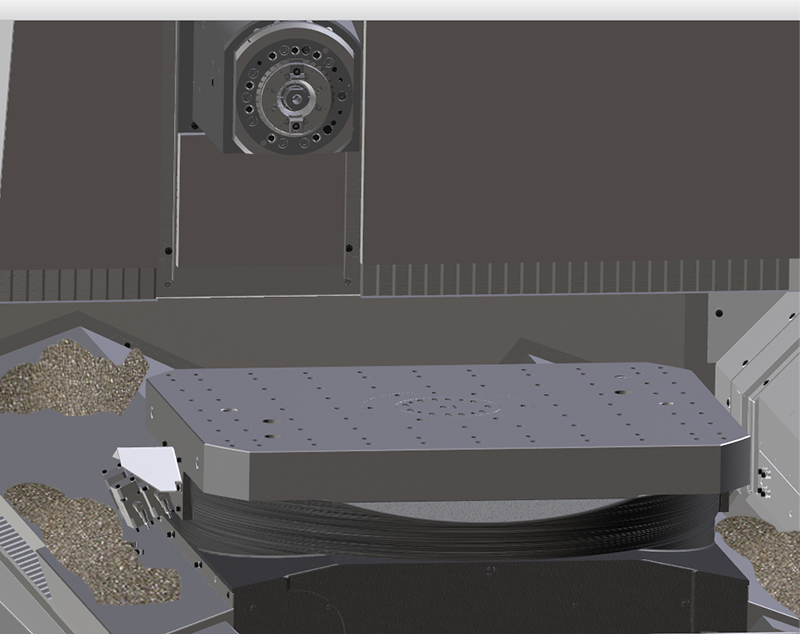

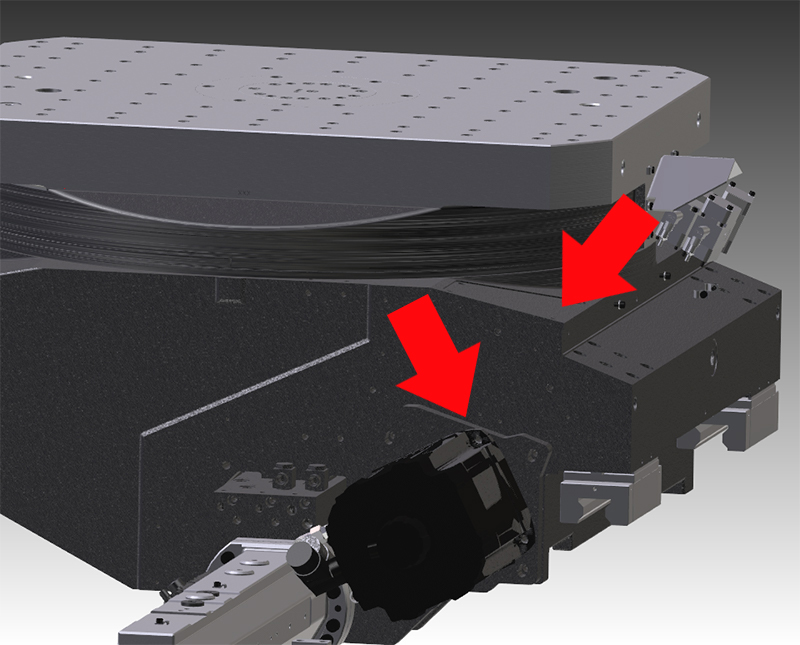

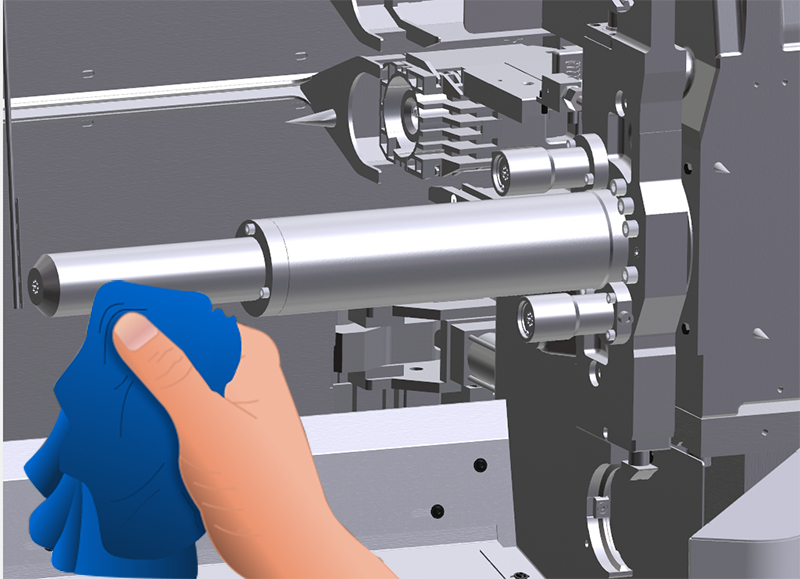

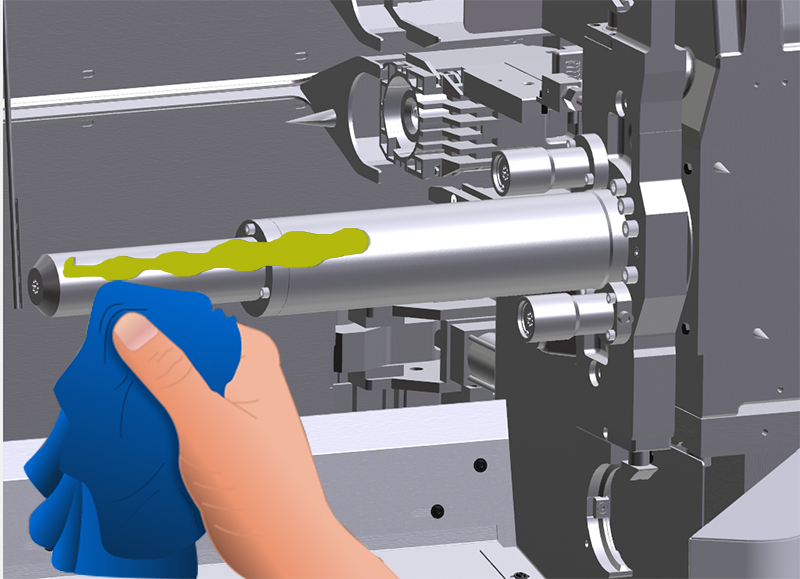

Used oil, grease and cooling lubricants, contaminated cleaning solutions and contaminated cloths should be regarded as special waste and disposed of according to the locally applicable regulations. Having made all machine areas accessible, take the opportunity to check all the fluid equipment. Proceed as follows to avoid doubling work: Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Danger to life within the traversing range of the gantry loader. Before climbing onto the machine, always move the portal loader to its parking position, switch off and secure to prevent it being switched on again. Do not remove gantry loader padlock before end of work or before removing the ladder. Proceed with caution if a tool is placed in the tool spindle whilst you are working within the work area. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Electrically protected doors, if available, open and secured to prevent closing. Step 10:Step 11:Step 12:Step 13:Step 14:Step 15:Step 16:Check all housings with oil filling for escaping oil.

Step 17:Check all fluid equipment components for leakages and visible external damage. For procedure, see: "Inspection of fluid equipment" Step 18:Step 19:Step 20:On machines with "oil pan" option:

Step 21: |