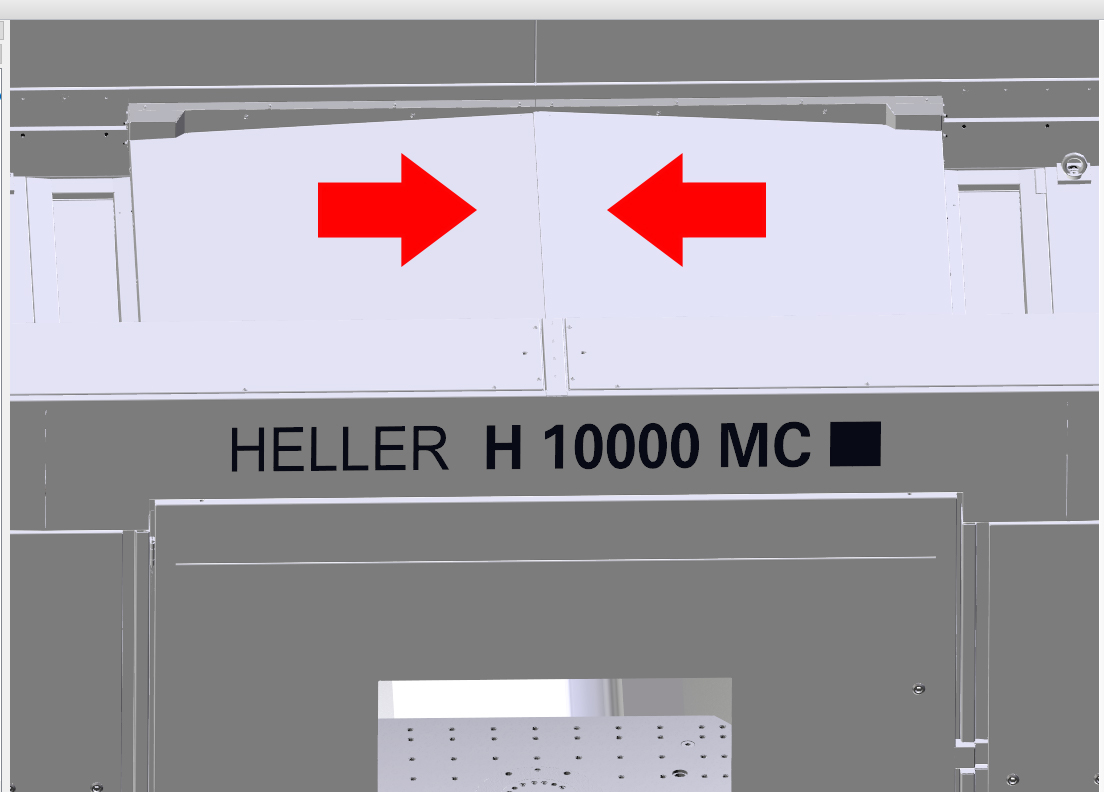

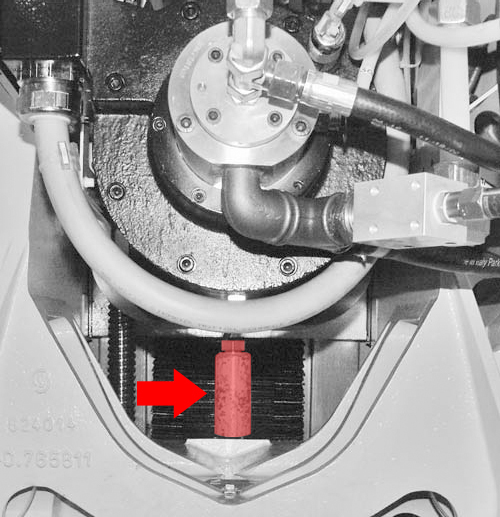

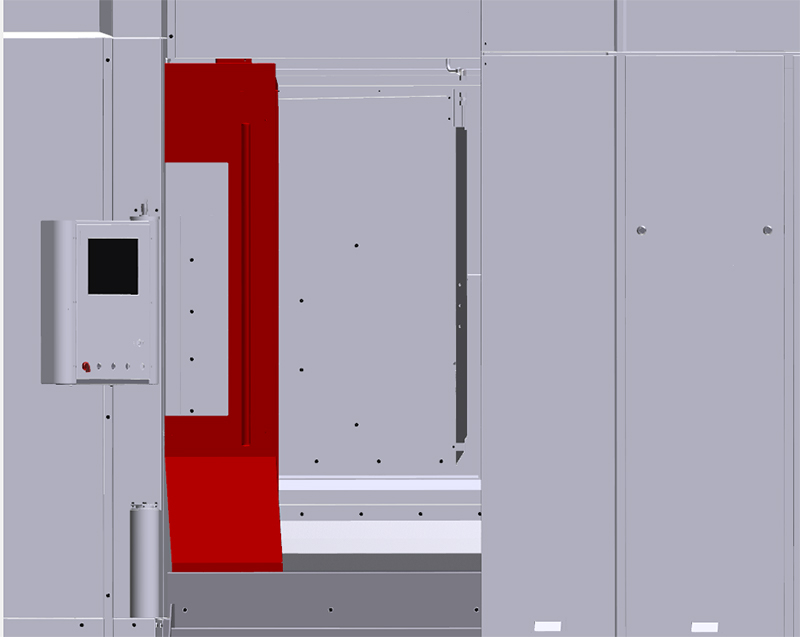

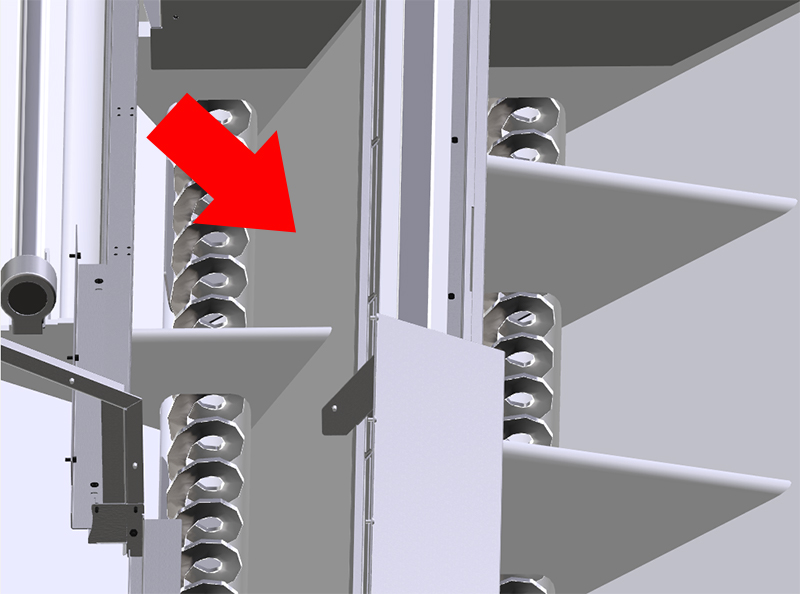

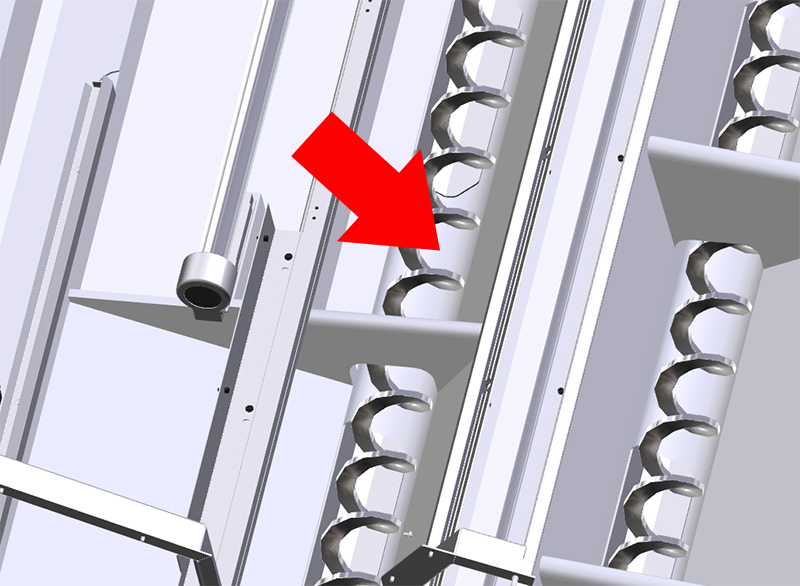

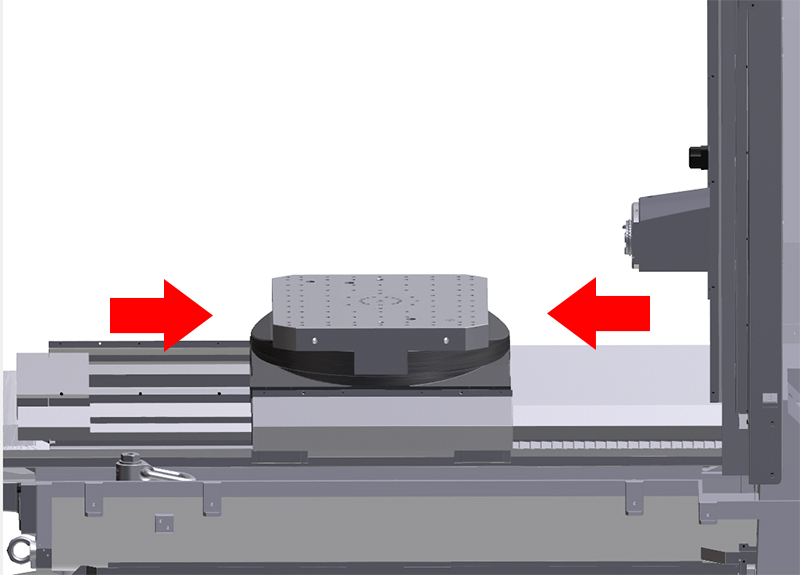

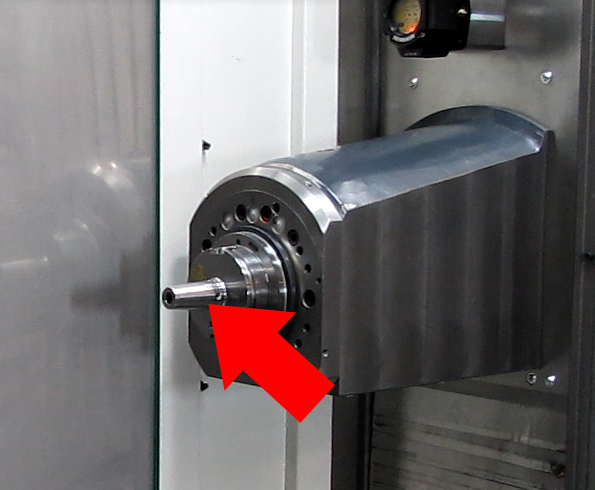

Check Conveyor Helixes and Slide Rails for WearInterval 2 Year(s) Real time Component Conveyor helixes and slide rails in machine bed The 3 conveyor helixes that transport the chips out of the work area are located on slide rails, which are screwed onto the conveyor channel. Certain types of chips may cause shrinkage of slide rails and conveyor helixes over the years, despite of their robust material. Replace the parts in good time. Wear limit is reached at the latest when the thickness of a slide rail decreases to 2 mm at the thinnes point. Always replace the entire set, conveyor helixes and slide rails. The following inspection is best carried out when the machine undergoes its annual basic cleaning. For slide rails and conveyor helixes, see wear and spare parts list. (VS). Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Prepare machine for operation. Move Z-axis to the machining unit, and check the side behind the rotary table in the same way. Step 12:Worn conveyor helixes and slide rails shall be replaced by the customer service. Step 13:Step 14:Before closing the safety doors, ensure that nobody is behind the guard panels. Close the work area safety door and the maintenance area safety door Step 15:Step 16:Step 17: |