Replace clamping bolt spring

Parts List

Reference Files

Tools Required

Torque Chart

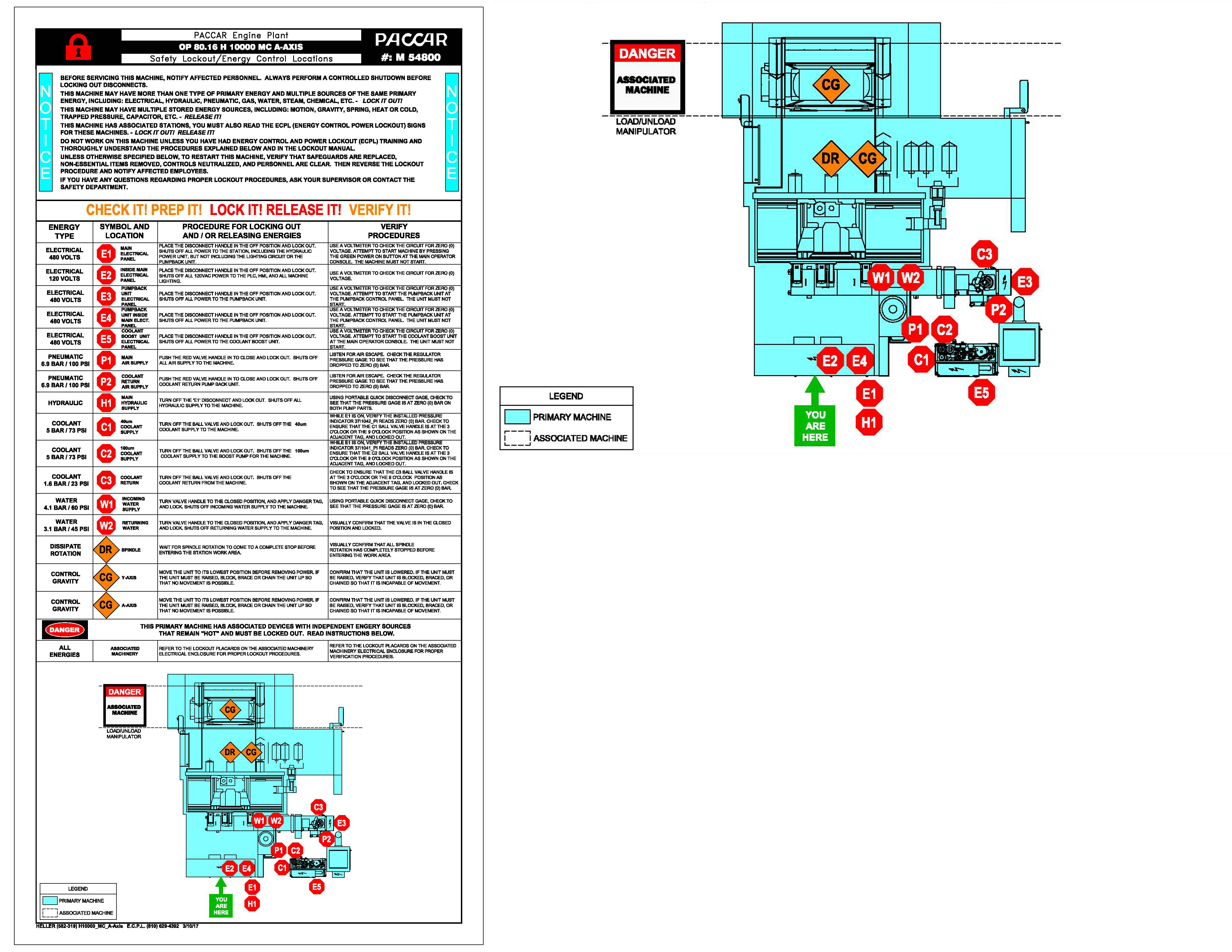

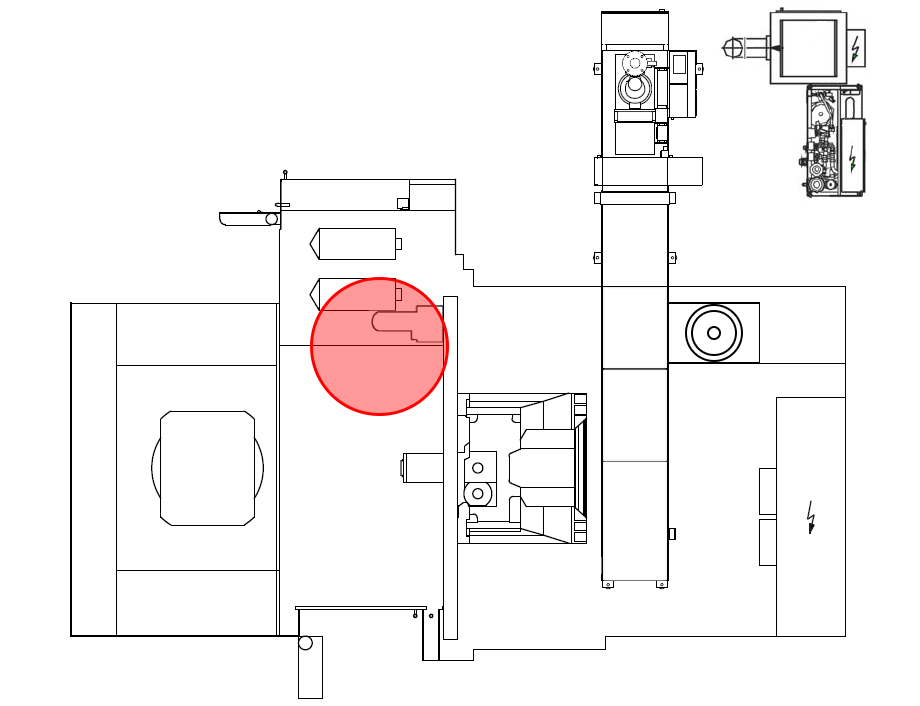

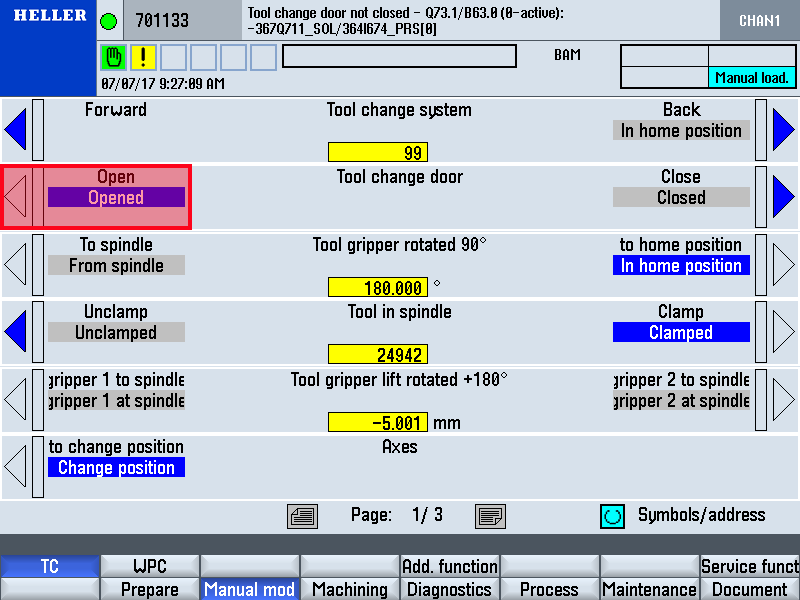

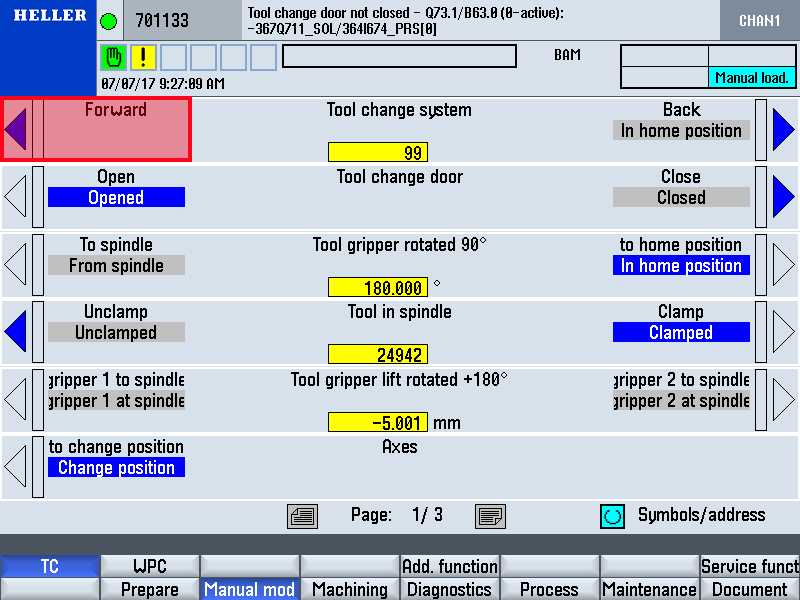

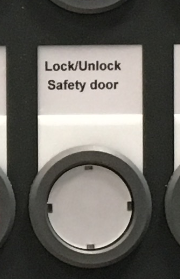

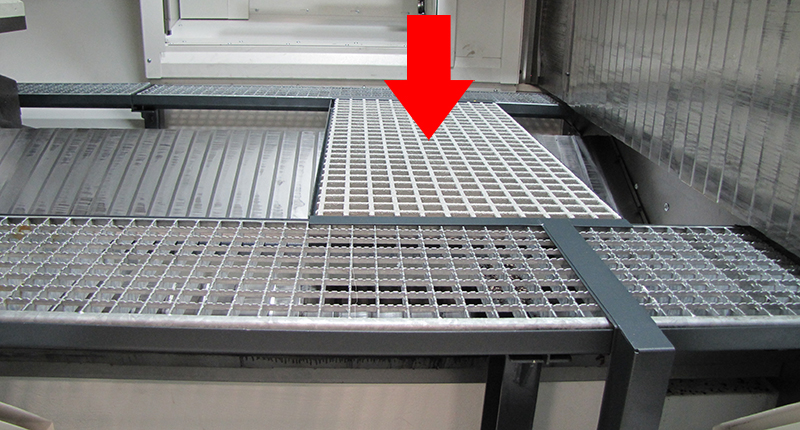

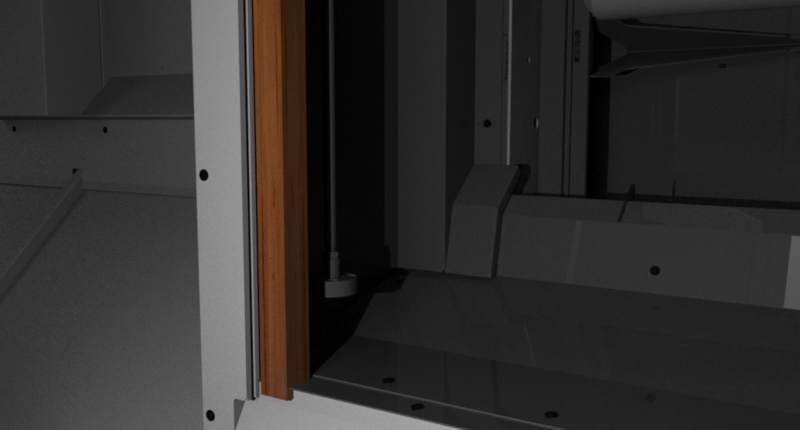

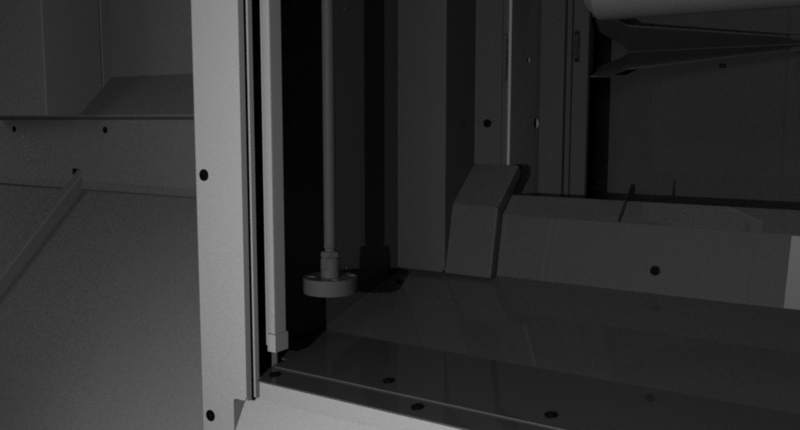

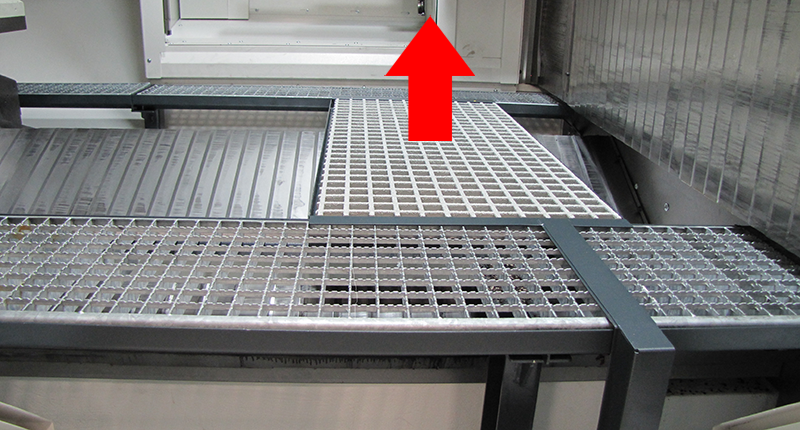

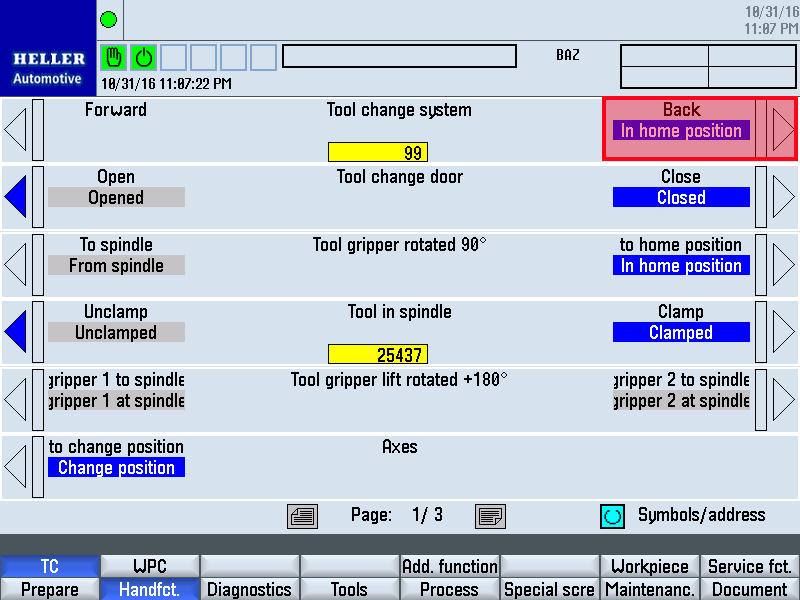

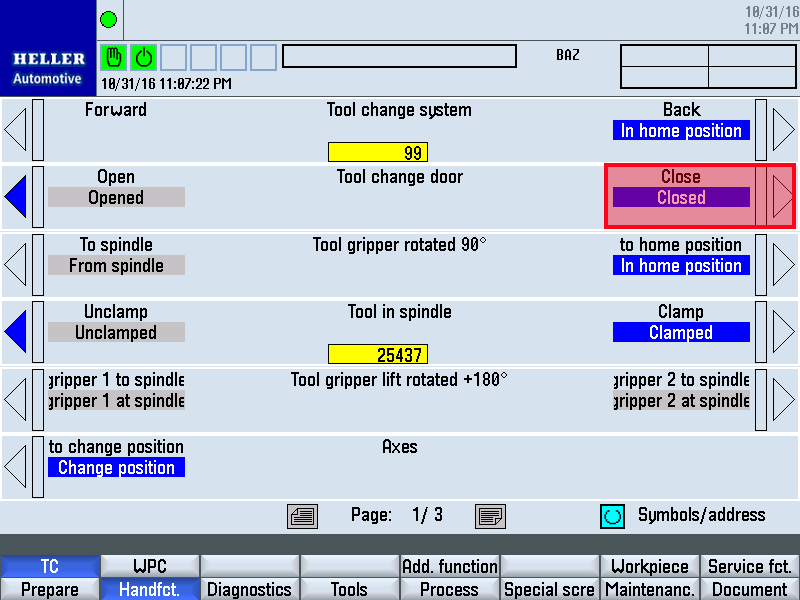

Step 1: ECPLStep 2: Open Tool Change DoorStep 3: Extend Tool ArmStep 4: Open Operator DoorStep 5: Install Work PlatformStep 6: Block Tool Change DoorStep 7: Loosen and Lower Tool Locking MechanismStep 8: Unscrew and Remove Clamping Bolt BushStep 9: Remove Ring and Cap "WARNING: Spring Under High Pressure!"Step 10: Remove Spring and Clean HousingStep 11: Grease SpringStep 12: Lubricate O Ring (Replace as Necessary)Step 13: Insert Spring and Ring and CapStep 14: Screw Bush InStep 15: Tighten Tool Locking MechanismStep 16: Remove BlockStep 17: Remove Work Place PlatformStep 18: Close and Lock Work Area Safety DoorStep 19: Return Arm to Home PositionStep 20: Close Tool Change DoorStep 21: ECPL |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||