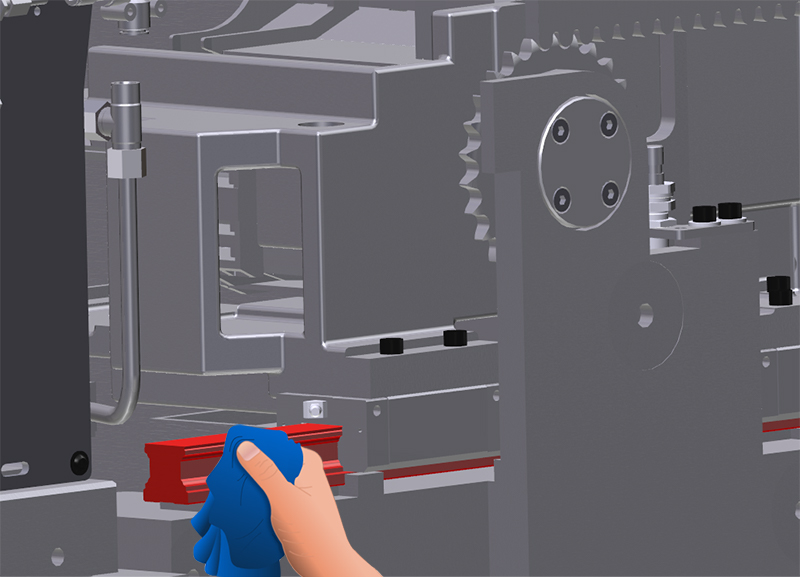

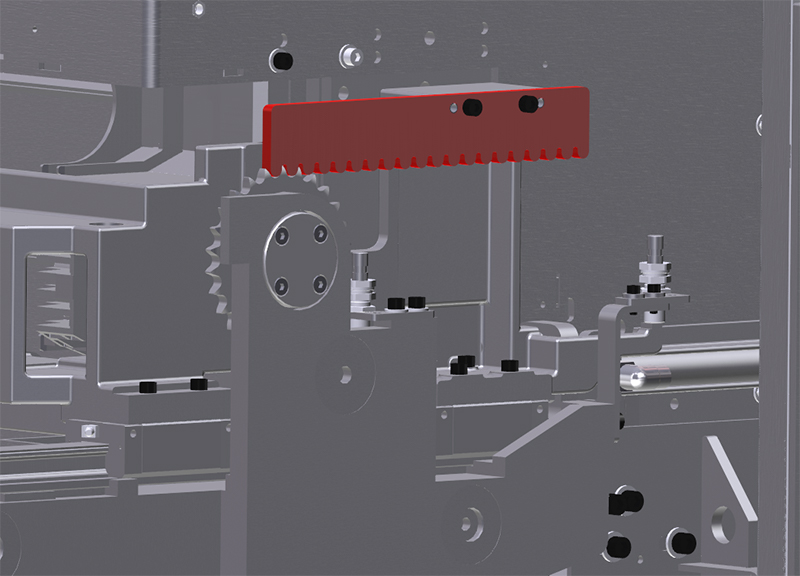

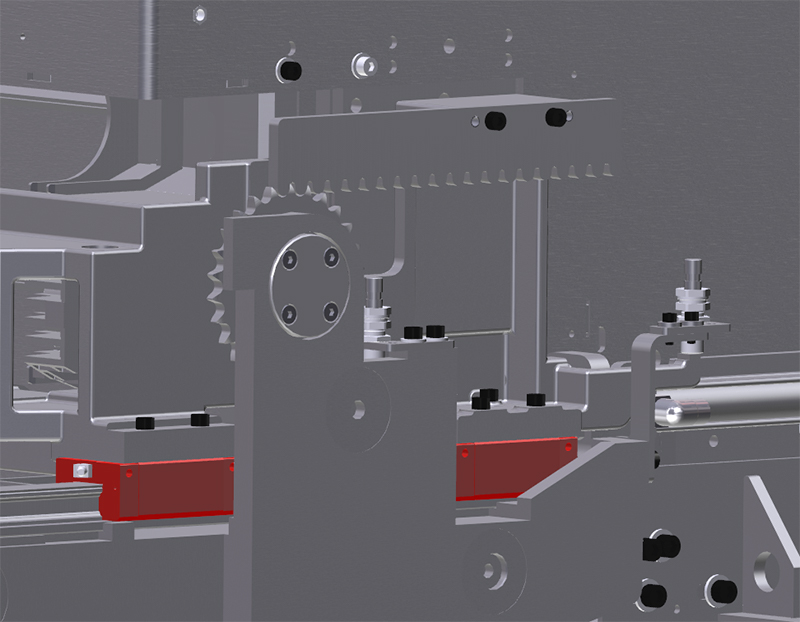

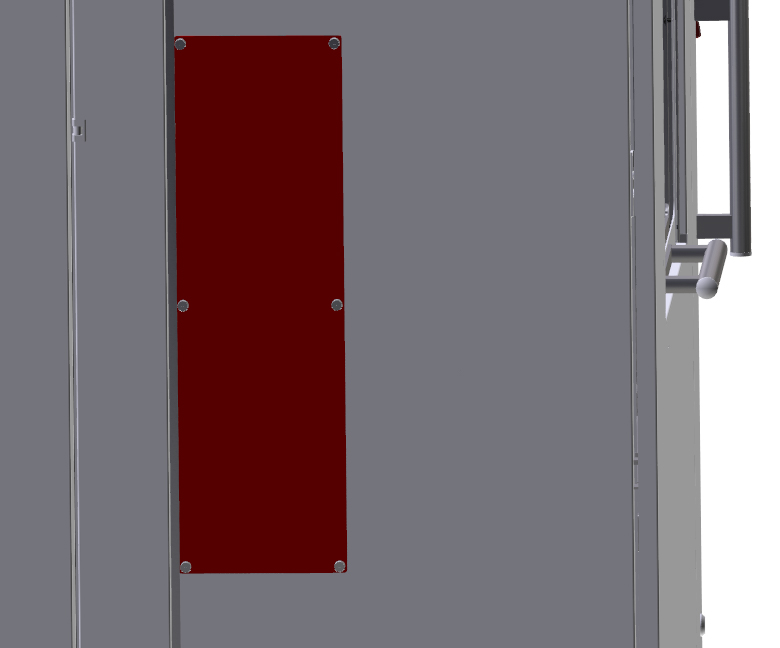

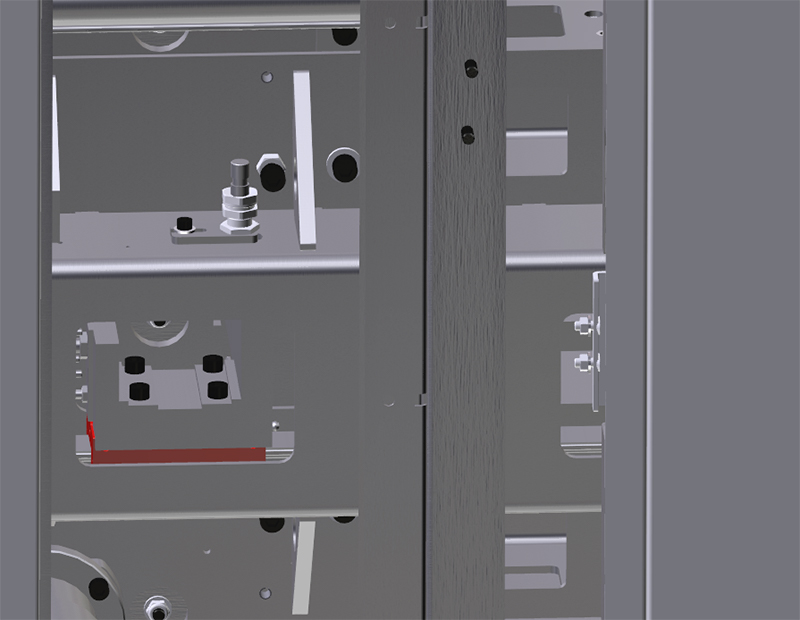

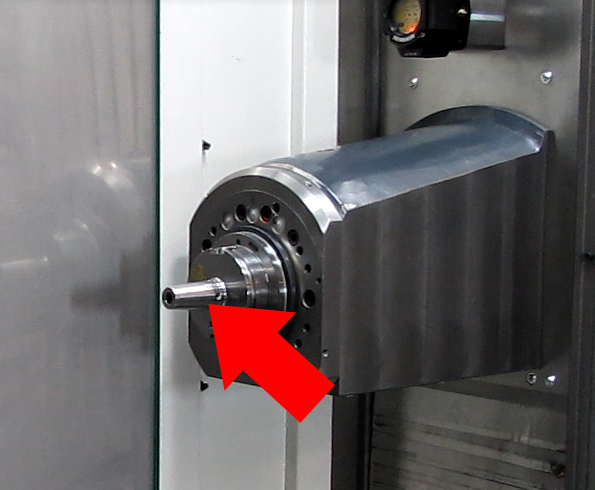

Lubricate Traverse Attachment and Guide of the Tool Setting StationInterval 2 Year(s) Real time Component Traverse attachment for tool transport between tool magazine and tool changer provisioning place, guideway of the slide for tool transport between tool magazine and tool setting station This work should be carried out as part of the basic machine cleaning operation. For basic cleaning of the machine, please refer to: "Cleaning the machine" Consumable Lubricating grease K2K-20 to DIN 51825, Part 2 Used greases and dirty cloths should be regarded as hazardous waste and must be disposed of according to the locally applicable regulations. Please observe "Special safety measures" when entering or leaving the machine. Exercise caution when working inside the machine with the machining unit not secured! Step 1:Step 2:Step 3:Step 4:Step 5:Re-lubricate the two runner blocks with the grease press until clean grease escapes from inside the runner block. Remove the used grease. Step 6:Step 7:Step 8:Re-lubricate the runner blocks with the grease press until clean grease escapes from inside the runner block. Remove the used grease. Step 9:Step 10:Step 11:Step 12: |