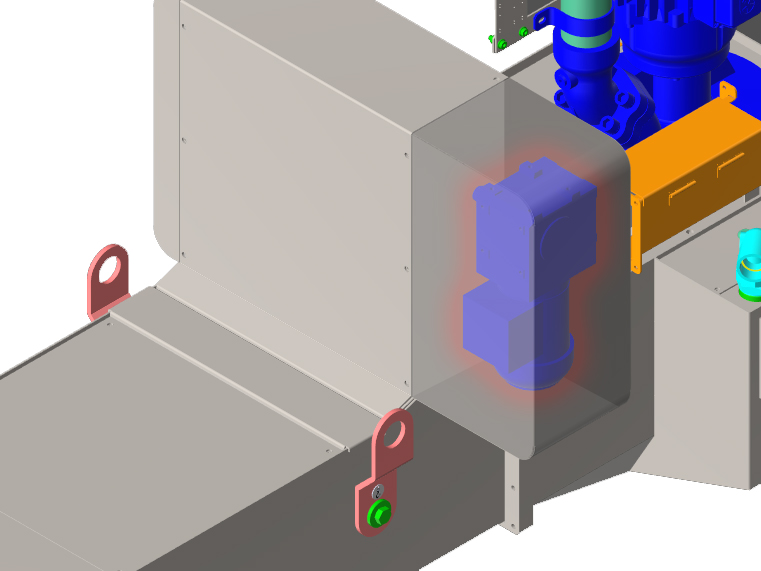

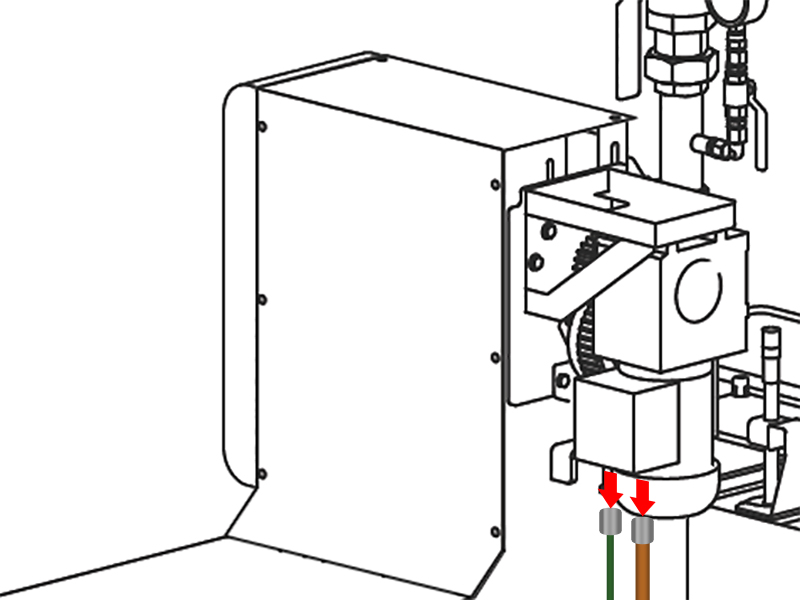

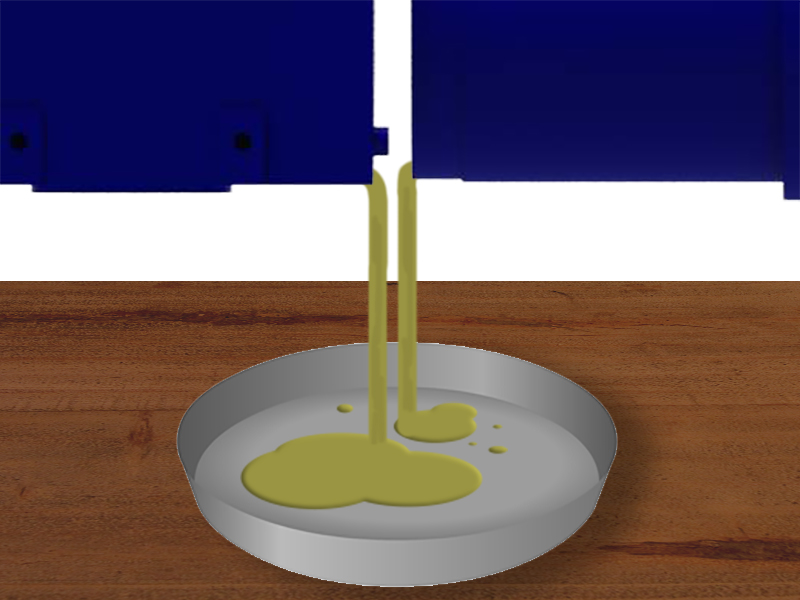

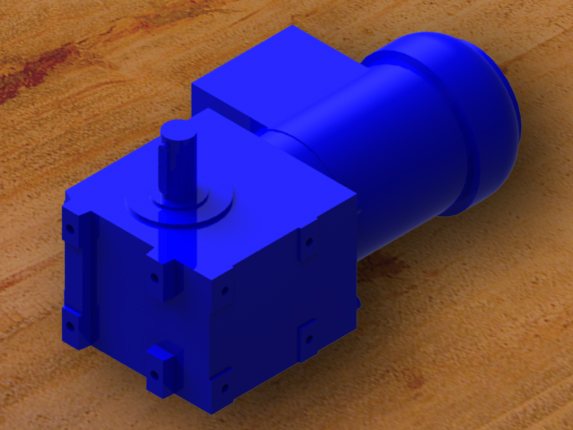

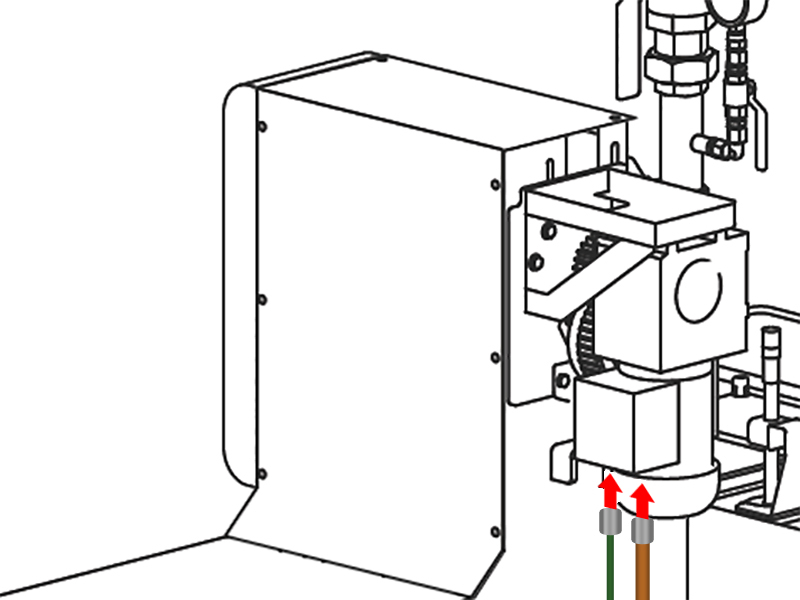

Oil Change on the Belt Drive Gear UnitInterval 3 Year(s) Real time Component Gear motor for driving the conveyor belt Consumable Synthetic lube oil CLP PG 220 according to DIN 51502 Purity class ISO 4406-18/16/13 Container capacity 0.42 l Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. Used oil must be regarded as hazardous waste and be disposed of according to the locally applicable regulations. Container for collecting the used lubrication oil For manufacturer's documentation on the gear motor, see Subsuppliers' Information (ZI) from "Knoll", documentation from Danfoss Bauer. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Drain-off oil:

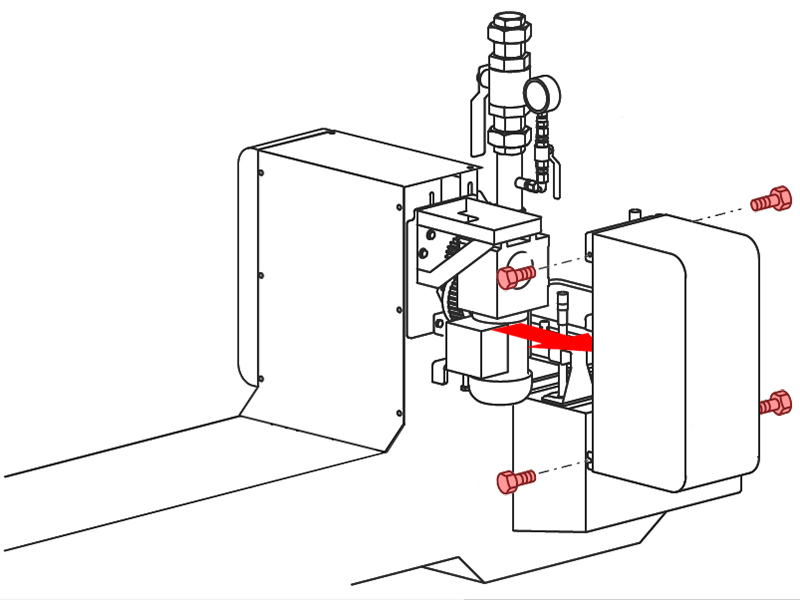

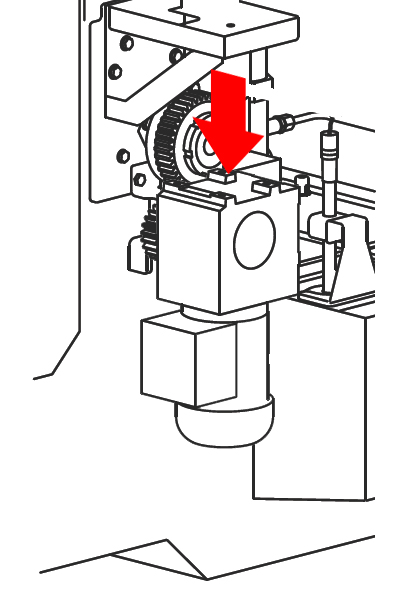

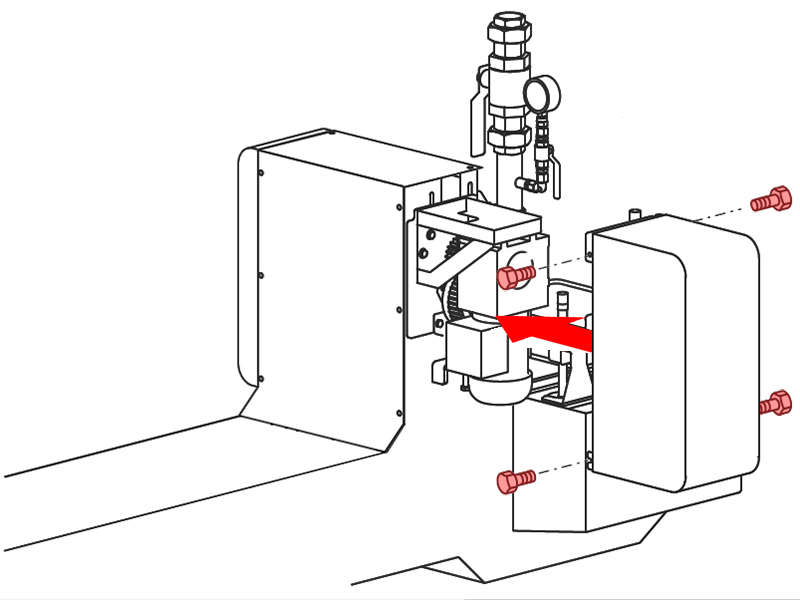

Step 9:Flush gear unit with fresh oil and refill. Step 10:Step 11:Insert the gear motor and fasten loosely:

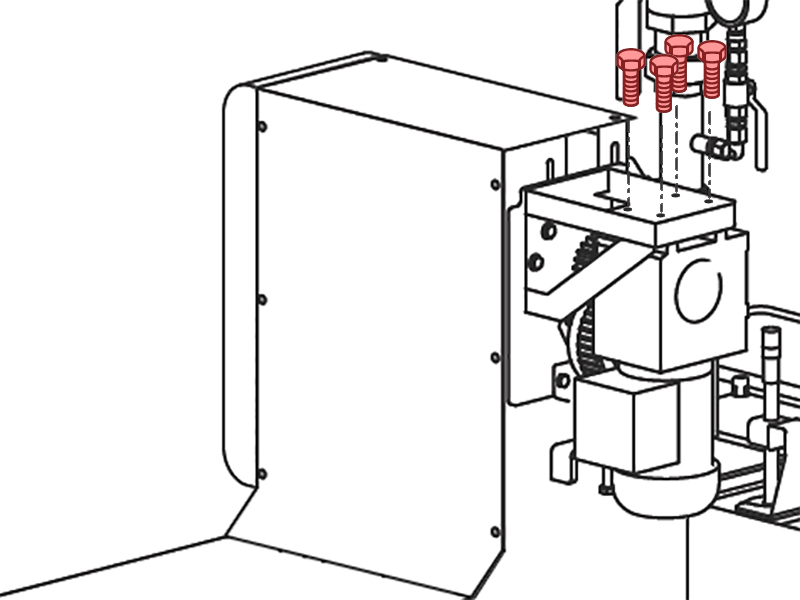

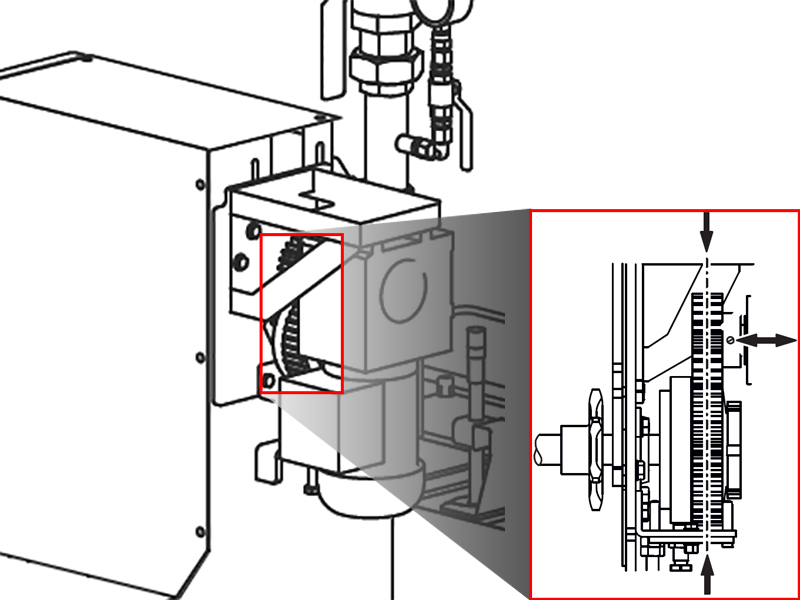

Step 12:Adjust and fasten gear motor:

Step 13:Step 14: |