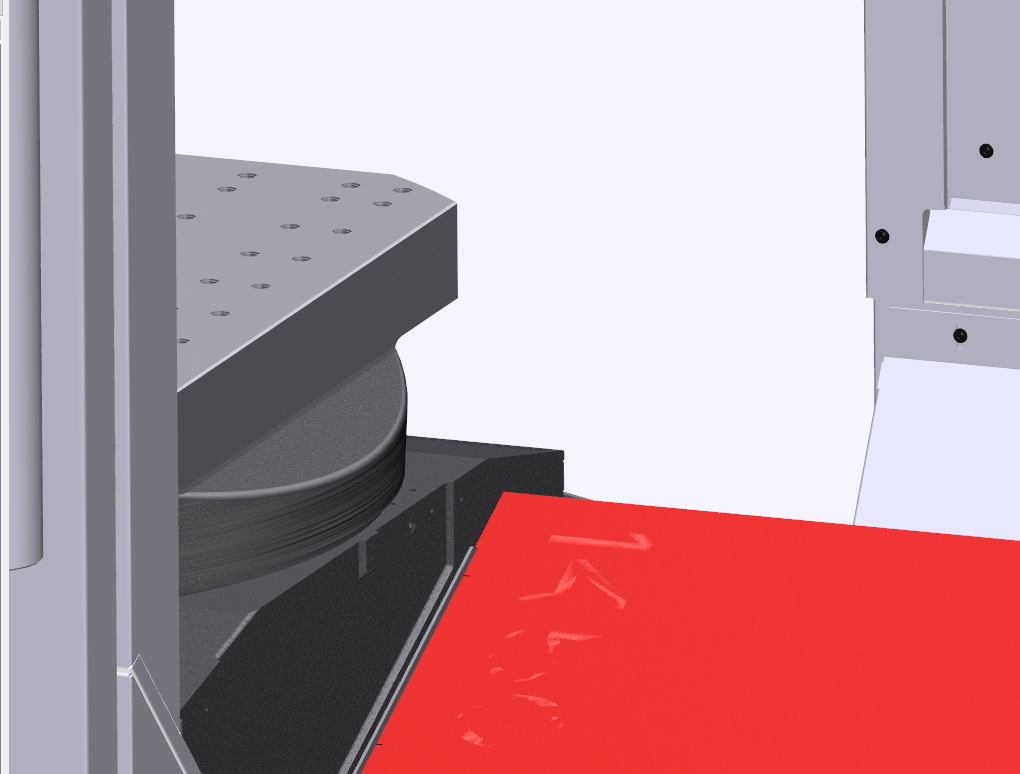

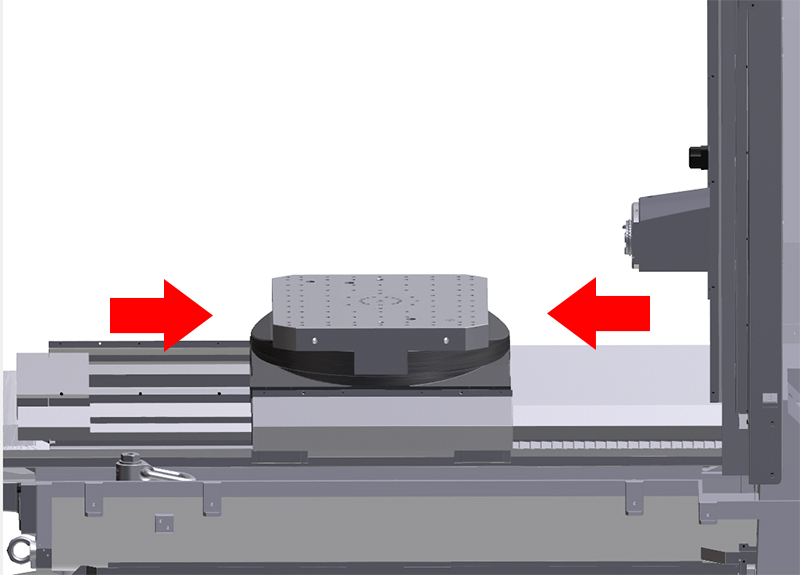

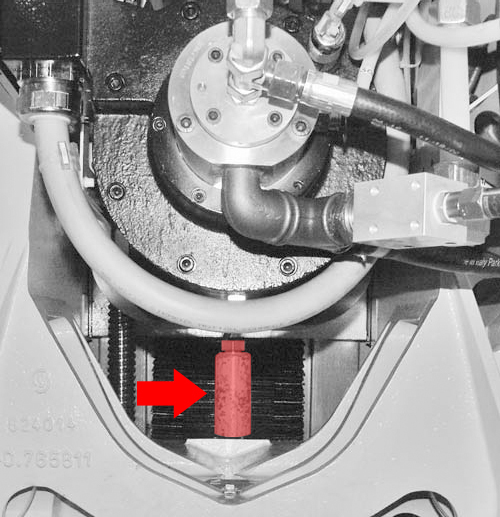

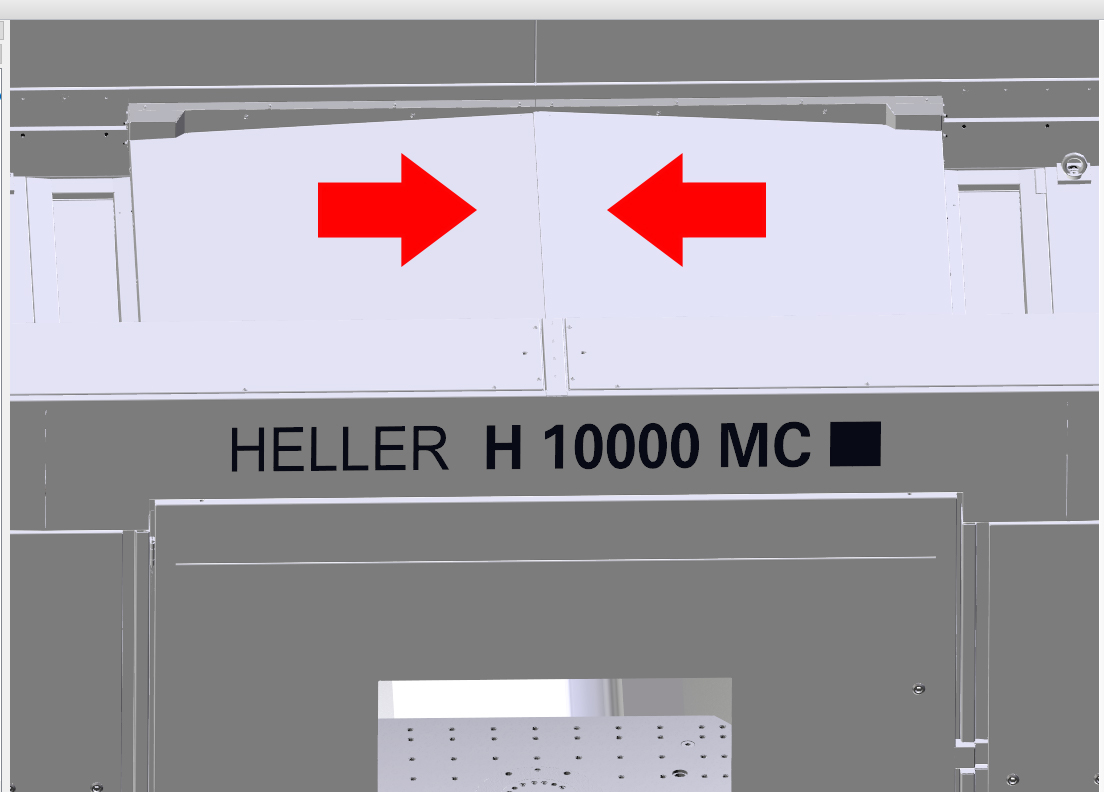

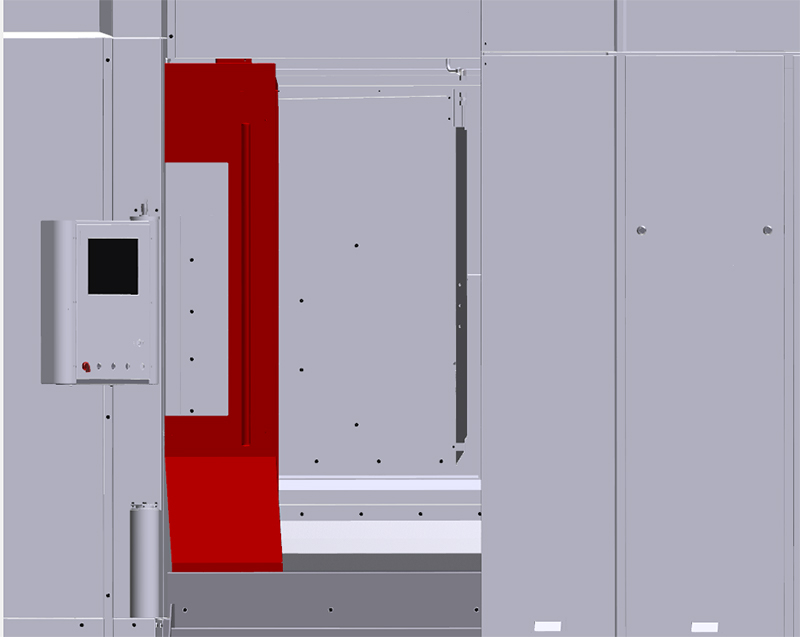

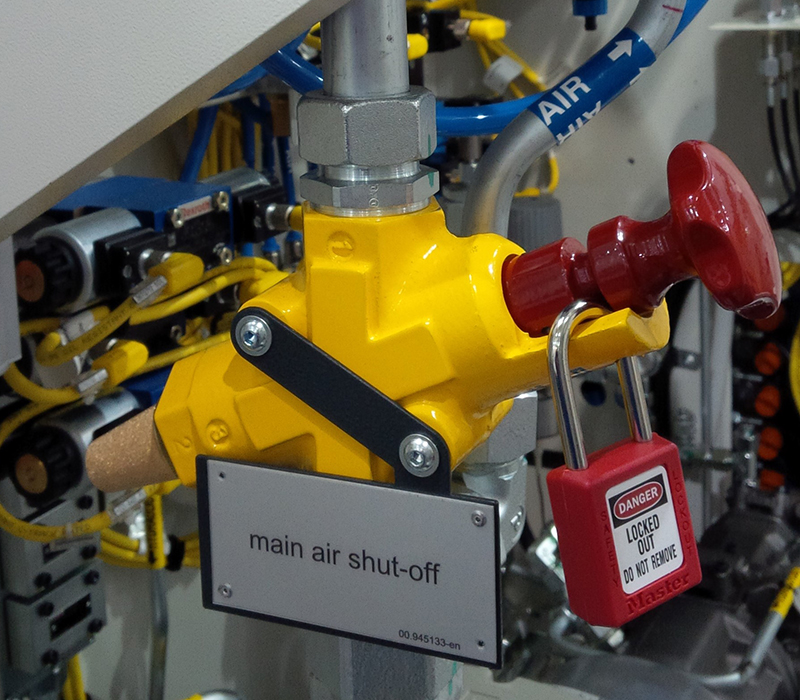

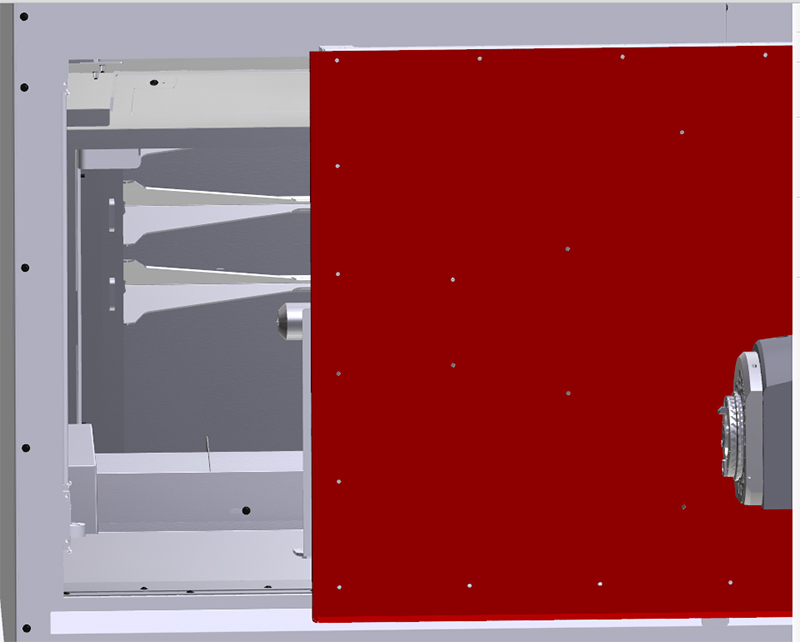

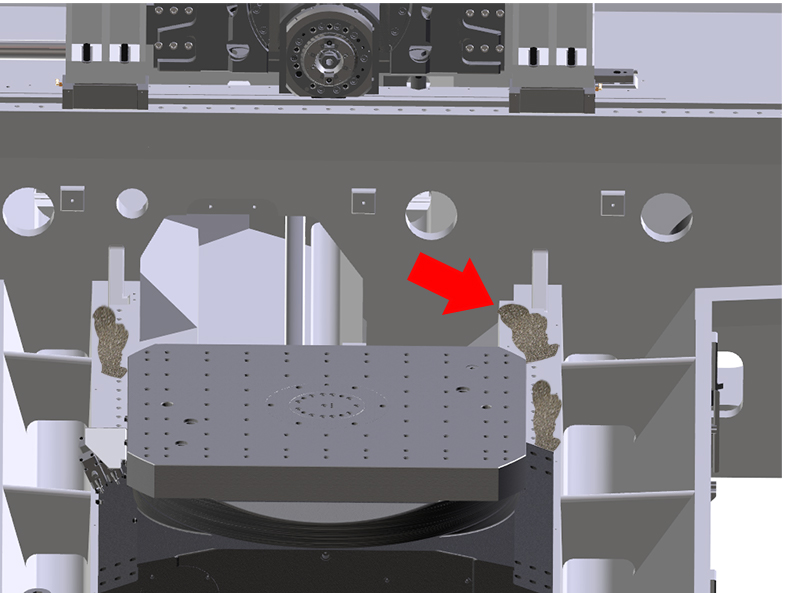

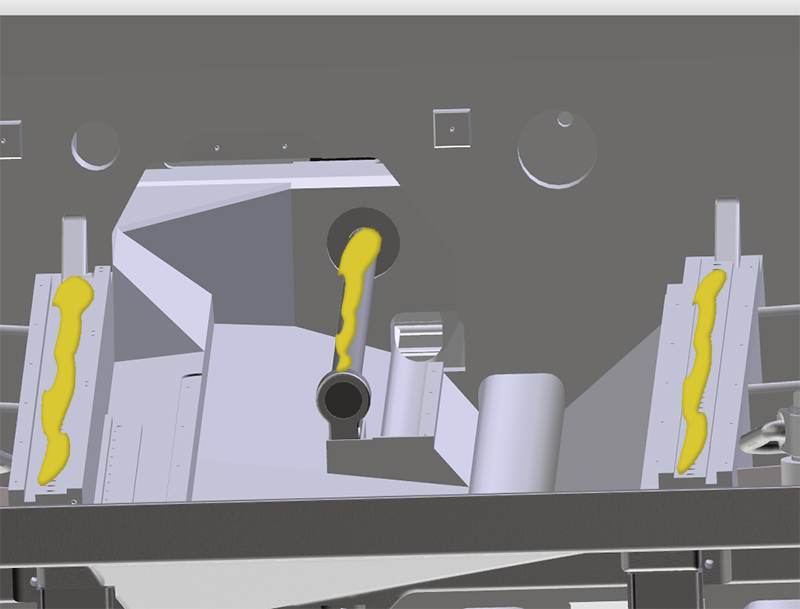

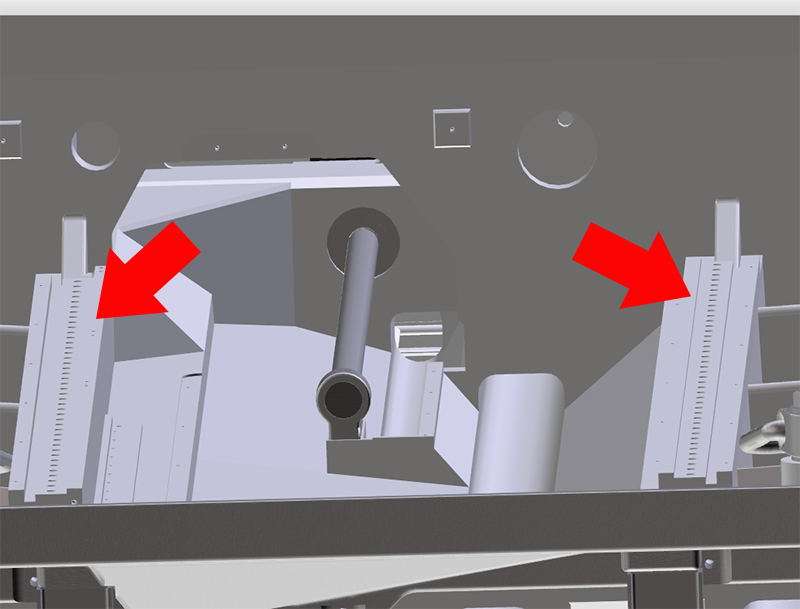

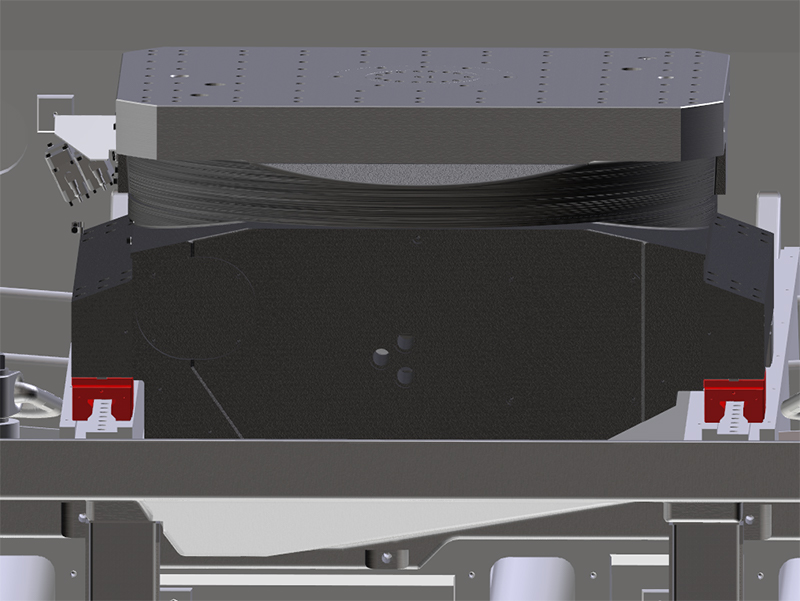

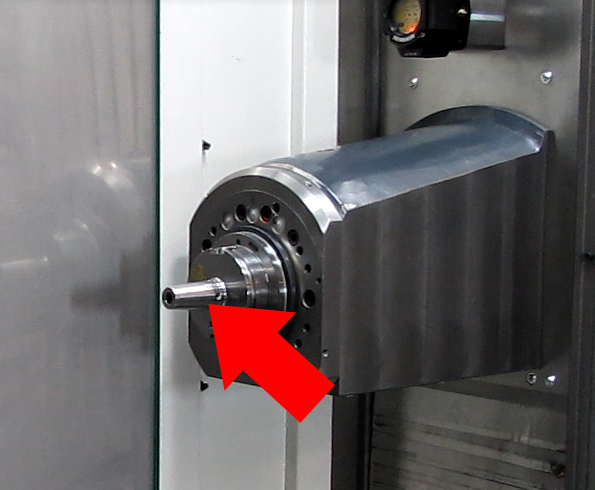

Checking Linear Roller Guides Axis DrivesInterval 2000 Hour Operating time Component Linear roller guides and axis drives for the X-, Y-, and Z-axes Spare part Guide carriages of the X, Y and Z-axis with integrated seal and outer seal. See wearing and spare parts list (VS). The Wear Parts List contains the factory-mounted cover strips. These are loose cover strips, tightly fitted and 0.30 mm thick. For raising and attaching the cover strips of the guide rails: Assembly aid lifting plate according to the installation instructions of Messrs. Bosch Rexroth. For installation instructions on replacing cover strips and wipers, see Subsupplier's Information (ZI) from "Bosch Rexroth". For lube points, see media diagram (MP). Make Axes AccesiblePlease observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Step 12:Maintenance door of the tool magazine opened and secured to prevent closing. (Only applicable with rack-type magazine) Step 13:Step 14:InspectionsWhere visible, check the components from all sides. One side of the X-axis is shown here as an example. Step 1:Step 2:Check lubrication of guideways and ball screw drives:

Step 3:

Inspect the rails to check that:

Step 4:Align an incorrectly seated cover strip according to the installation instructions of Messrs. Bosch Rexroth. Step 5:In the event of damage, shut down the machine. Call customer service. Do not operate machine with damaged guide! Indentations, scoring, scratches and discolouration indicate a faulty runner block. Guide rail/cover strip and both runner blocks must be replaced if any of these appear. Step 6:Check wipers on runner block for penetrated swarf. If chips have penetrated or the wiper is damaged, replace the complete sealing set. Step 7:Prepare machine for operationStep 1:Step 2:Step 3:Before closing the safety doors and maintenance openings, ensure that nobody is behind the guard panels. Close safety doors and maintenance openings. Step 4:Step 5:Step 6:Traverse Z-axis to and from over the entire stroke and check that the concertina covers are running smoothly. Step 7:Step 8: |