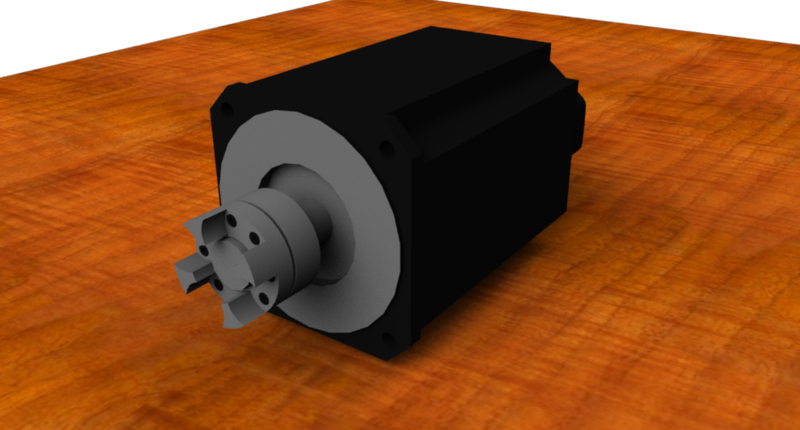

Y-Axis Motor Replacement

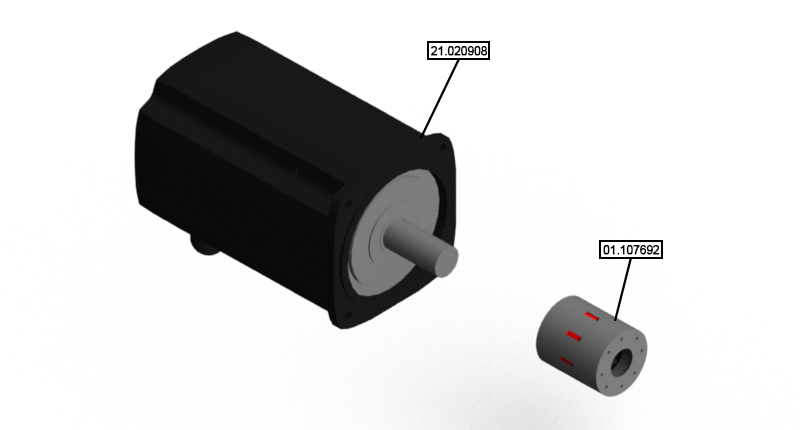

Parts List

Reference Files

Tools Required

Torque Chart

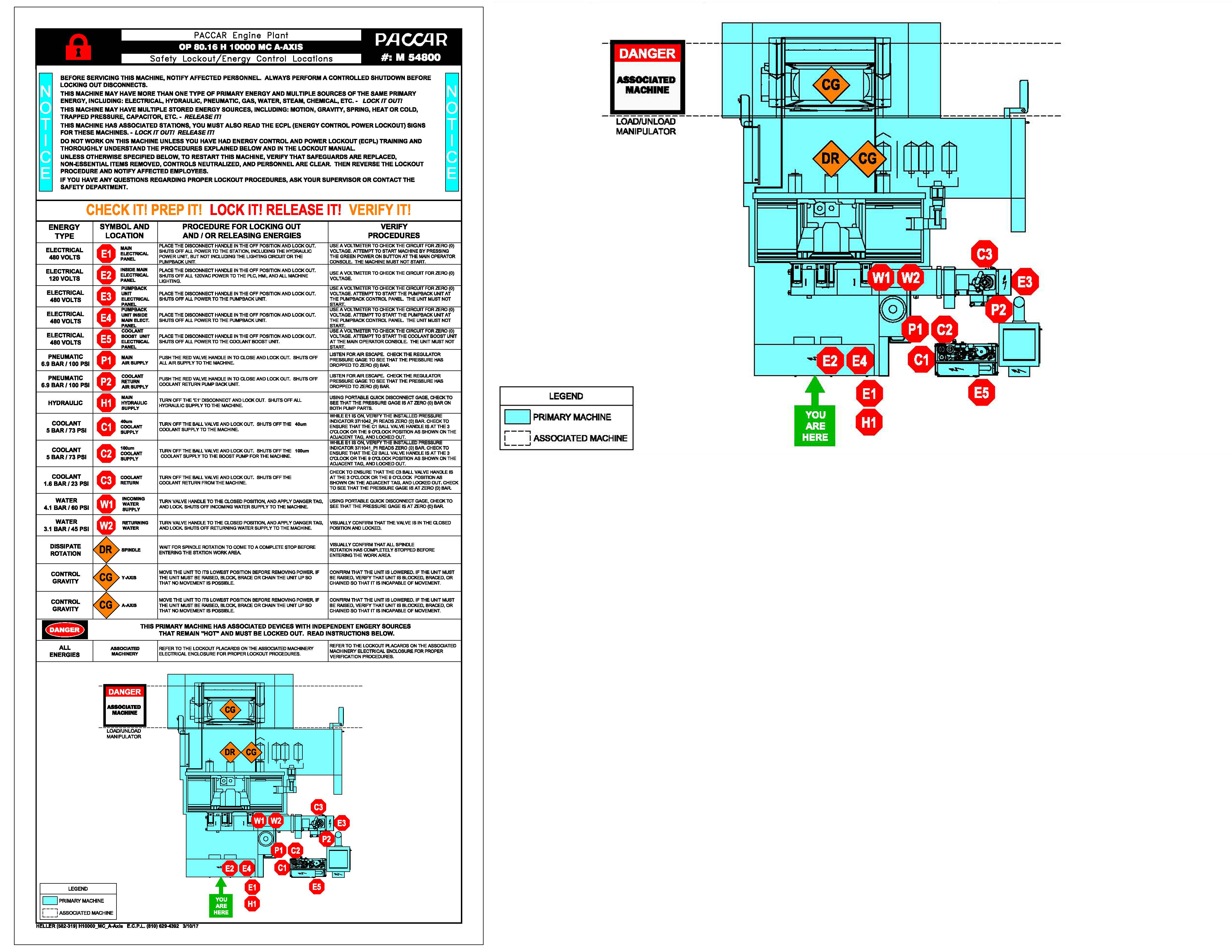

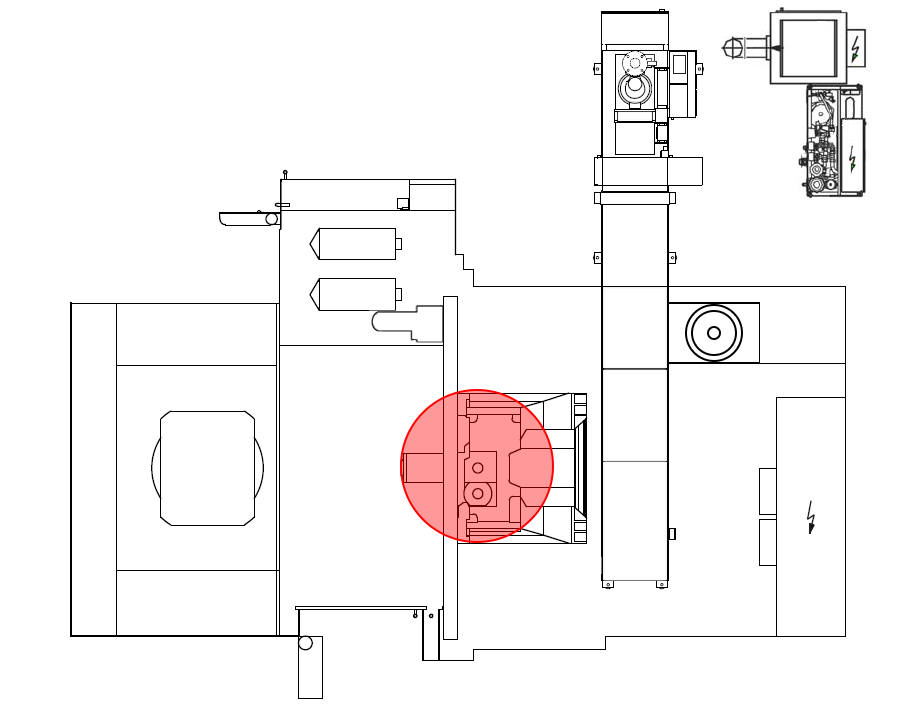

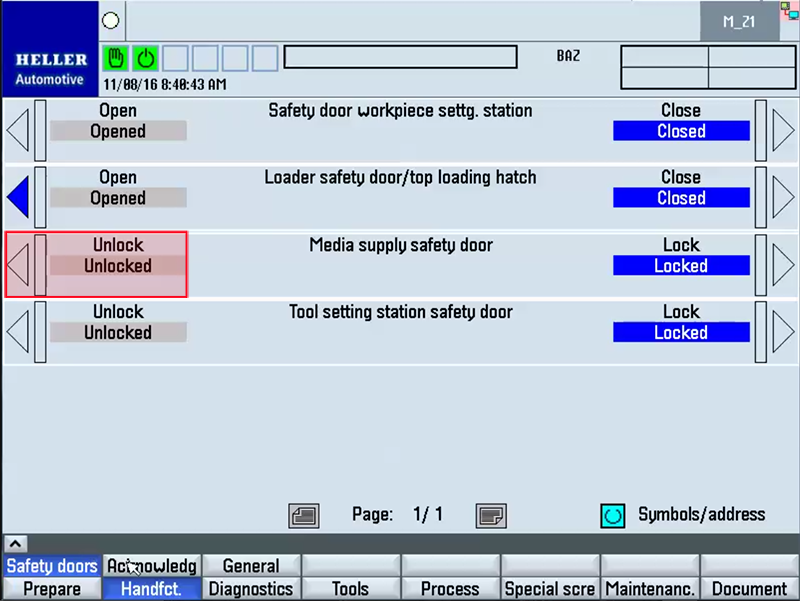

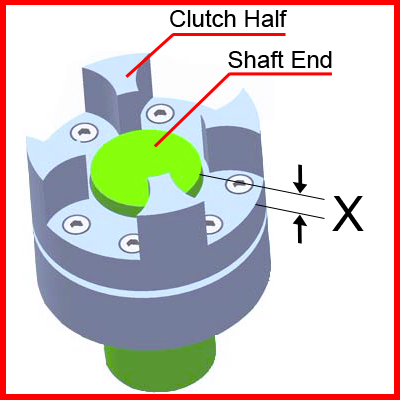

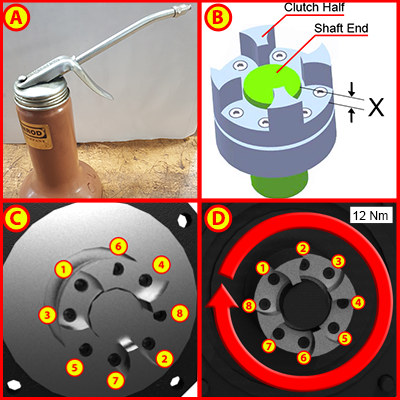

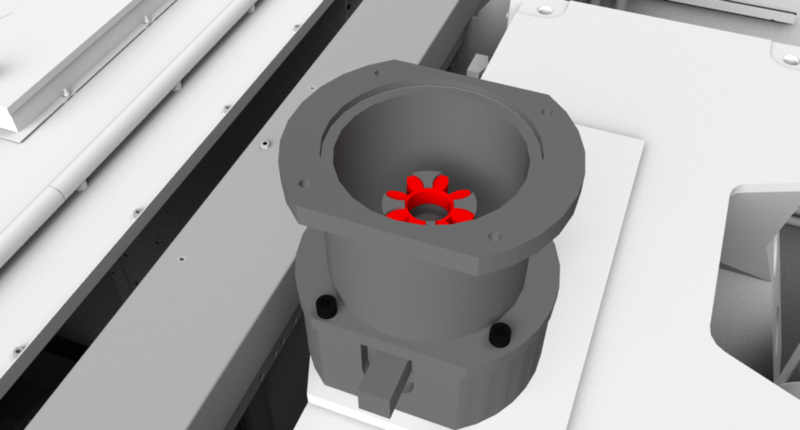

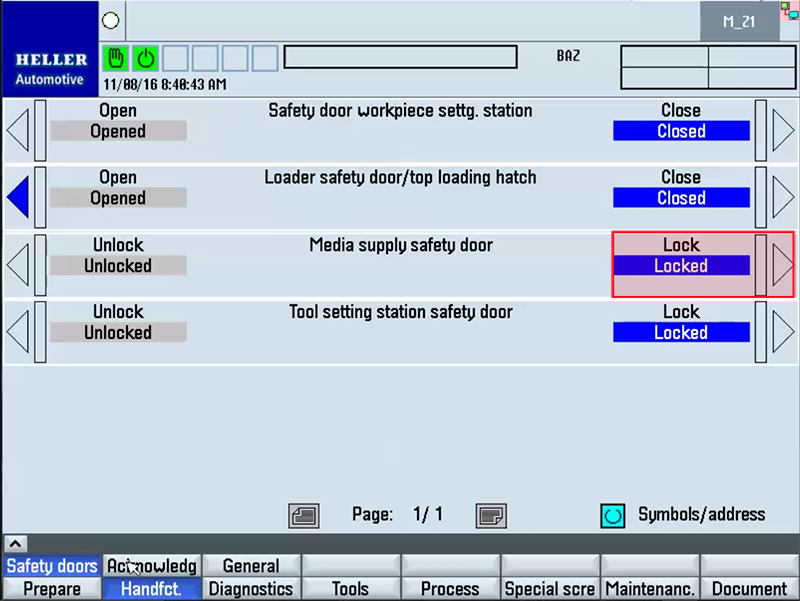

Step 1: ECPLStep 2: Open Maintenance DoorStep 3: Secure Machine From FallingStep 4: Remove Electrical Connection and Secure MotorStep 5: Remove MotorStep 6: Measure CouplingStep 7: Lubricate Motor / Measure Coupling / Install Screws / TorqueStep 8: Remove CouplingStep 9: LubricateStep 10: Install CouplingStep 11: Install Absorbing InsertStep 12: Secure Motor With lifting DeviceStep 13: Make Sure Mounting Surface is CleanStep 14: Install MotorStep 15: Remove Lift Assist / Install Motor ConnectionsStep 16: ECPLStep 17: Close Maintenance DoorStep 18: Jog AxisStep 19: Open Maintenance DoorStep 20: Remove BlockStep 21: Close Maintenance DoorStep 22: ECPL |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||