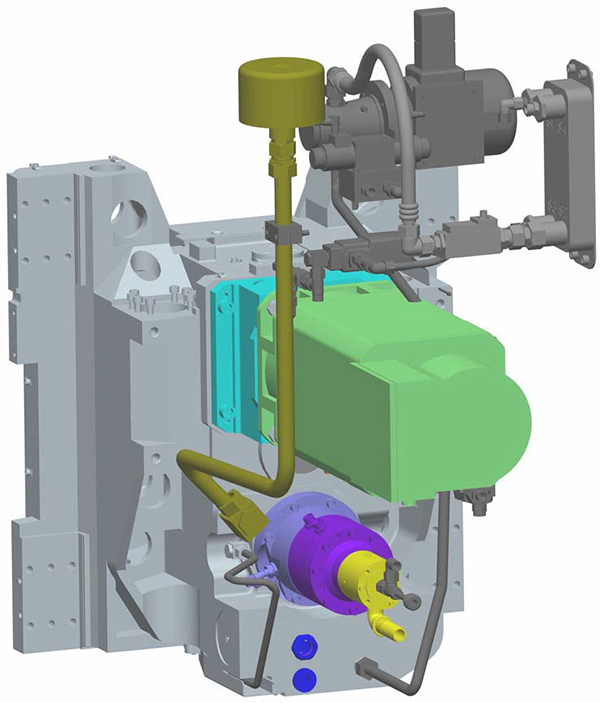

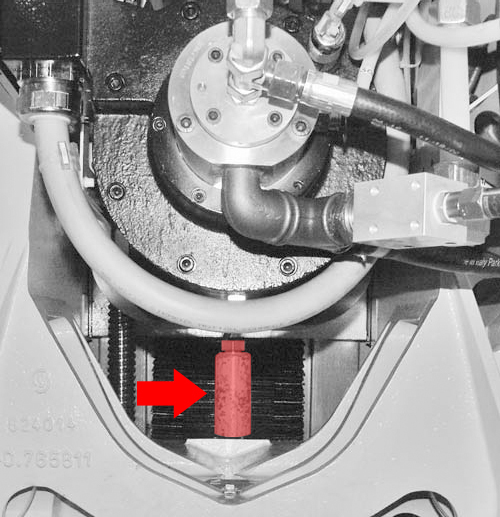

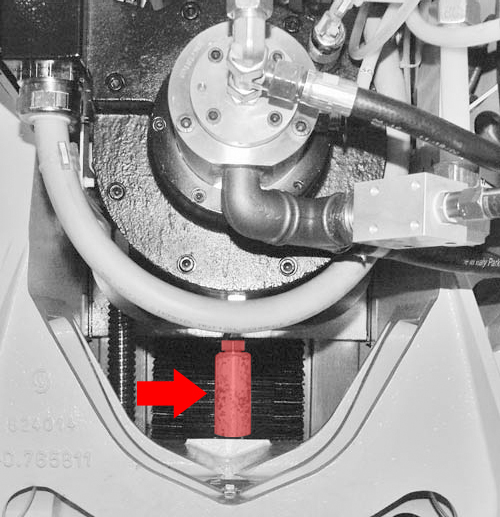

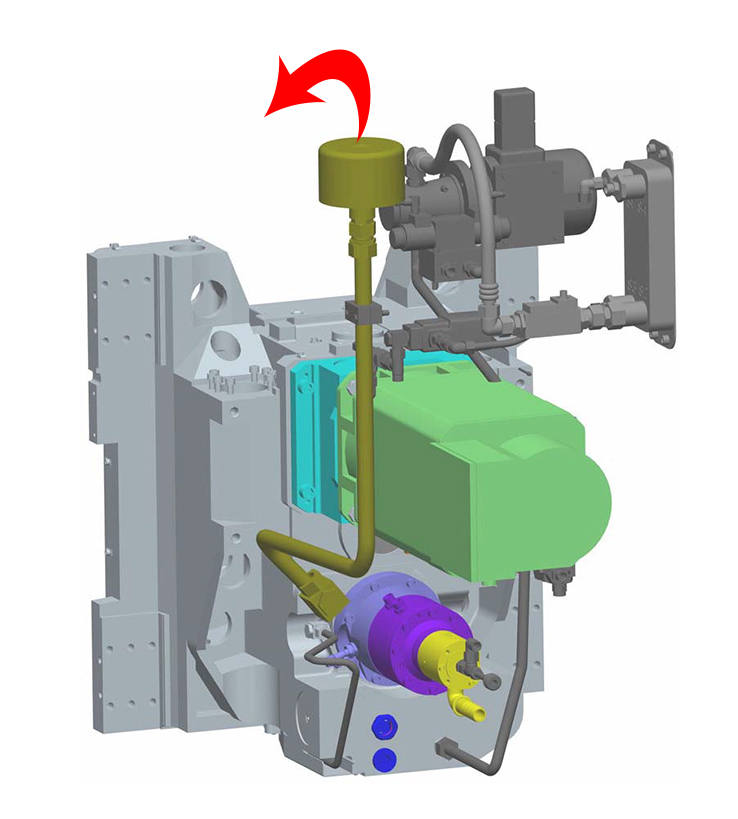

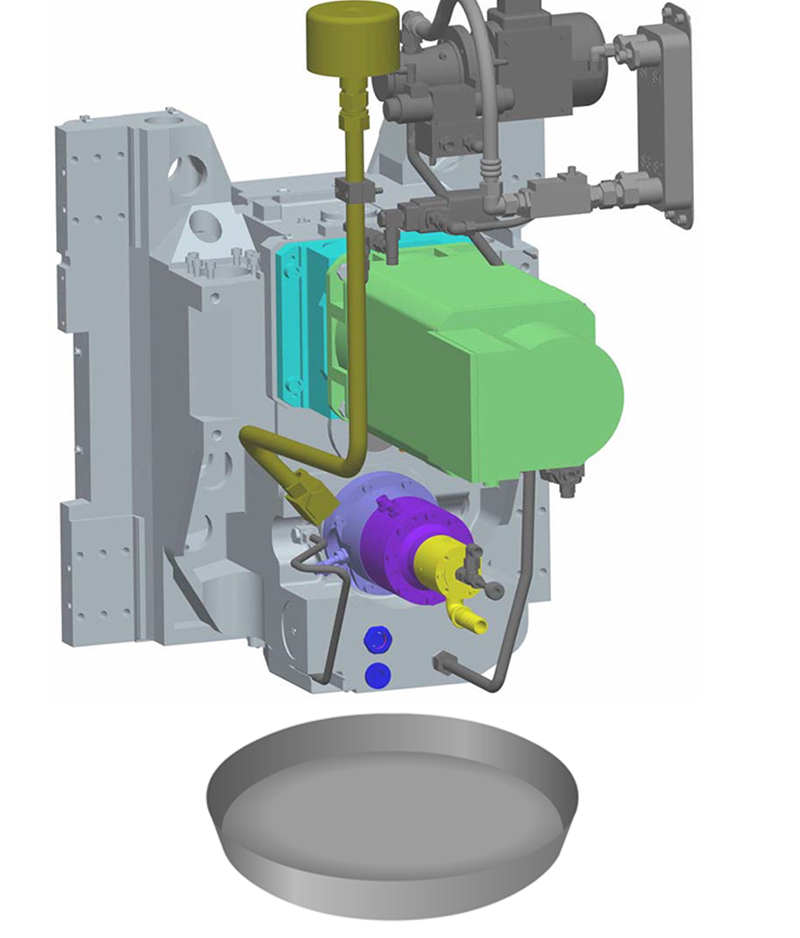

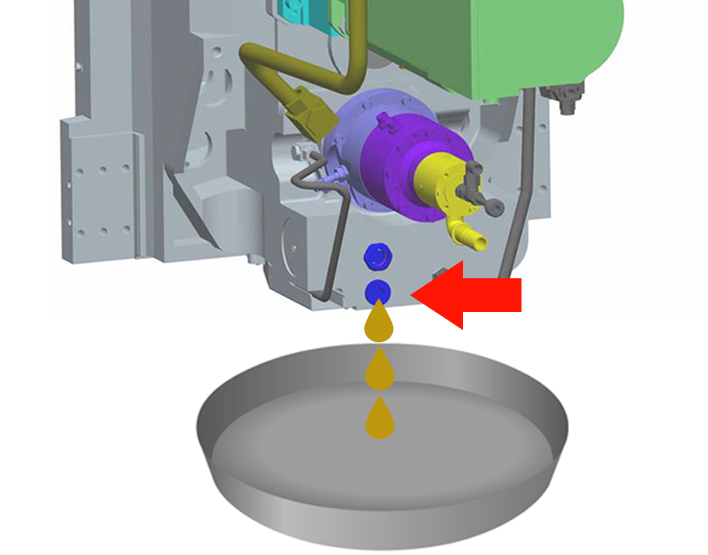

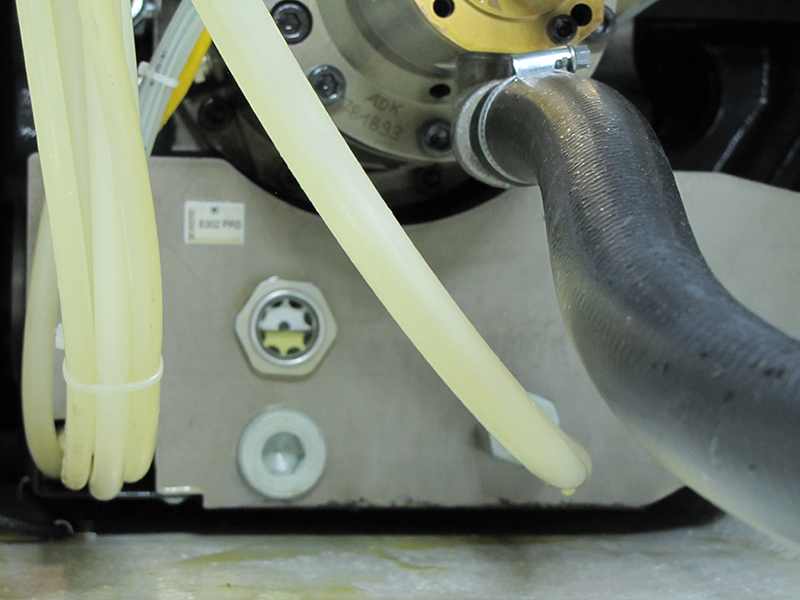

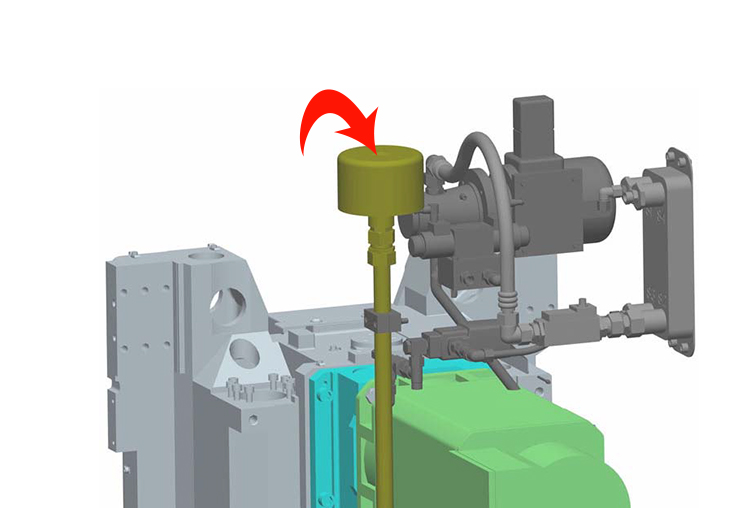

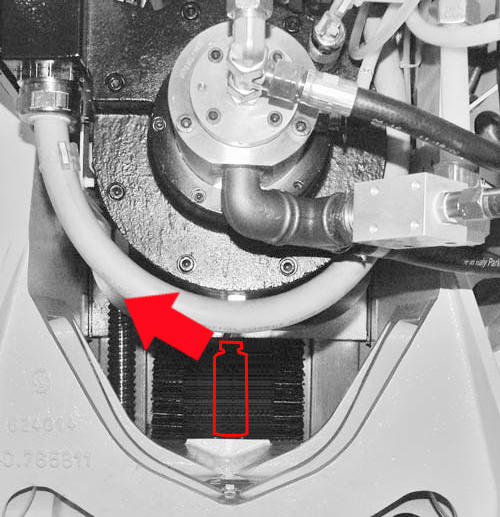

Oil Change in the Guide SlidesInterval 1 Year(s) Real time Component Guide slides of the machining unit Consumable Lubrication oil CLP 46 acc. to DIN 51517, part 3 (ISO-L-CKC 46 acc. to ISO 6743, part 6) Purity class ISO 4406-18/16/13 Container capacity 5 l Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. Used oil must be regarded as hazardous waste and be disposed of according to the locally applicable regulations. Spare part Oil filter screw with seal: screw plug

Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Step 12:Step 13: |