Replacing Gear Motor

Parts List

Reference Files

Tools Required

Torque Chart

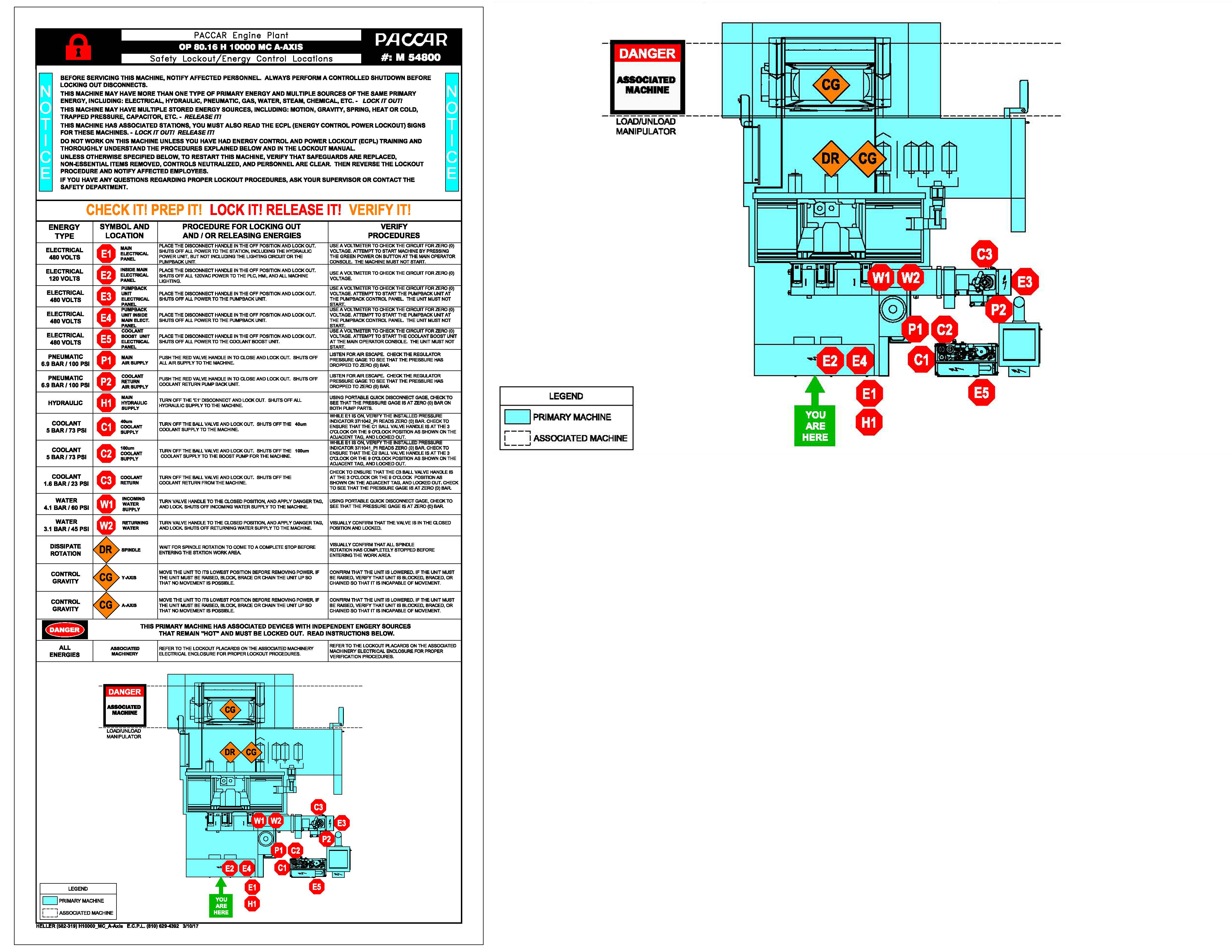

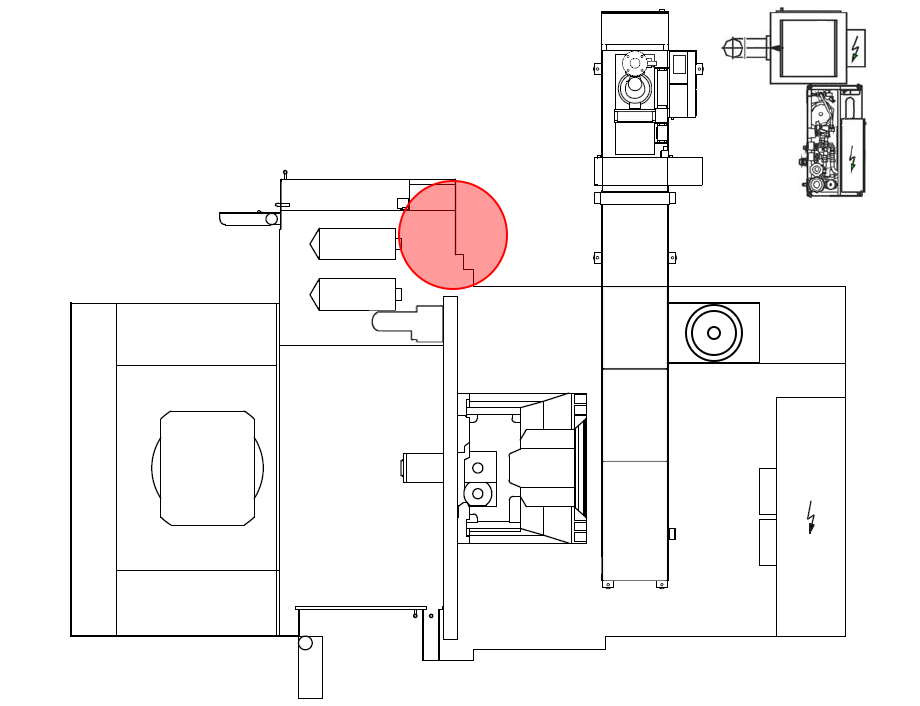

Step 1: ECPLStep 2: Secure With Lifting Device and Remove Motor CablesStep 3: Remove Orifice Screws and Orifice PanelStep 4: Unscrew Fixing ScrewsStep 5: Rotate MotorStep 6: View From Assembly OpeningStep 7: Pull Motor OutStep 8: Remove Servo Motor Screws and Pull Motor OffStep 9: Reinstall Servo MotorStep 10: Mount Motor OnStep 11: Rotate Motor Back and Tighten Clamping BoltStep 12: Rotate and Tighten Fixing ScrewsStep 13: Place Orifice Panel and Insert Orifice SrewsStep 14: ECPL |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||