Replace ZT1 axis drive motor

Parts List

Reference Files

Tools Required

Torque Chart

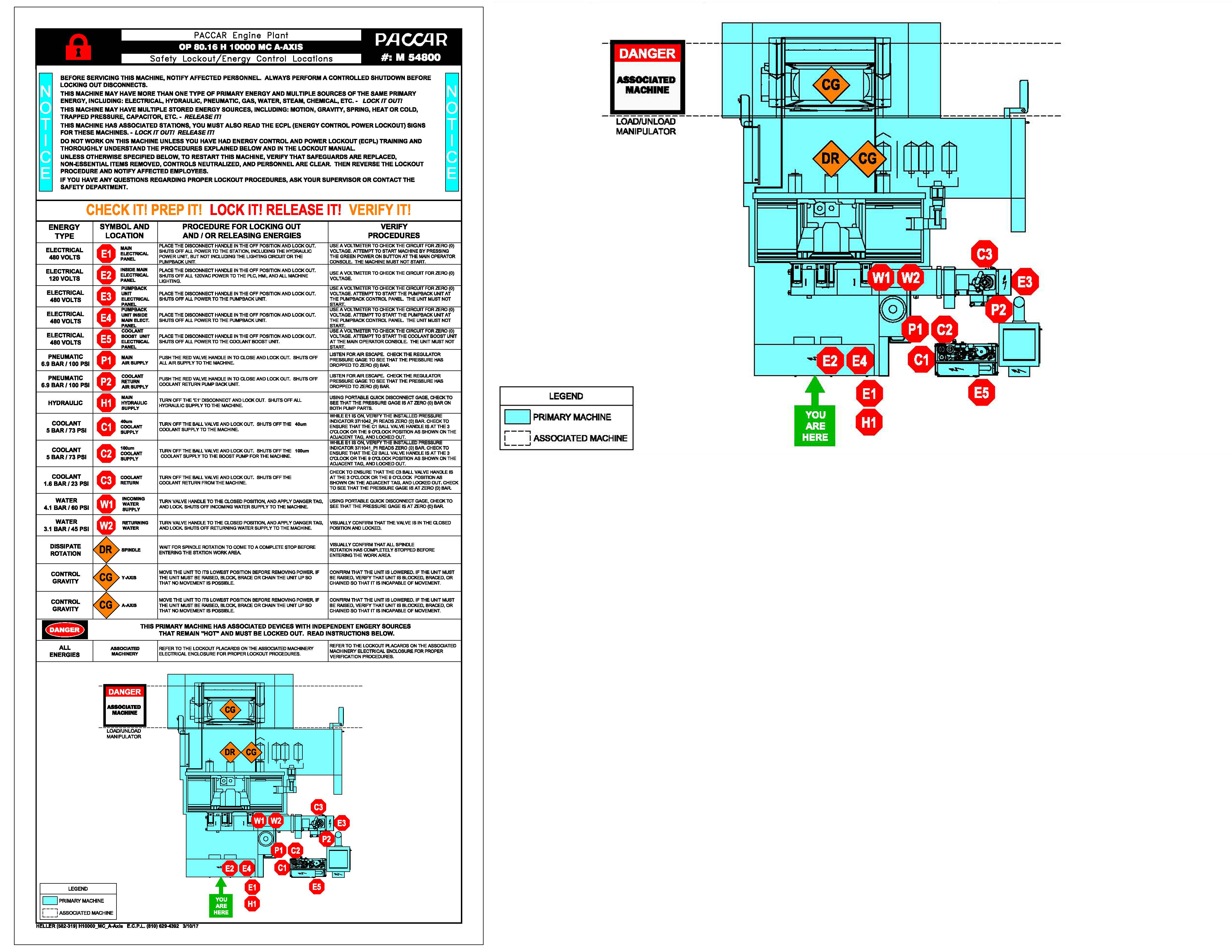

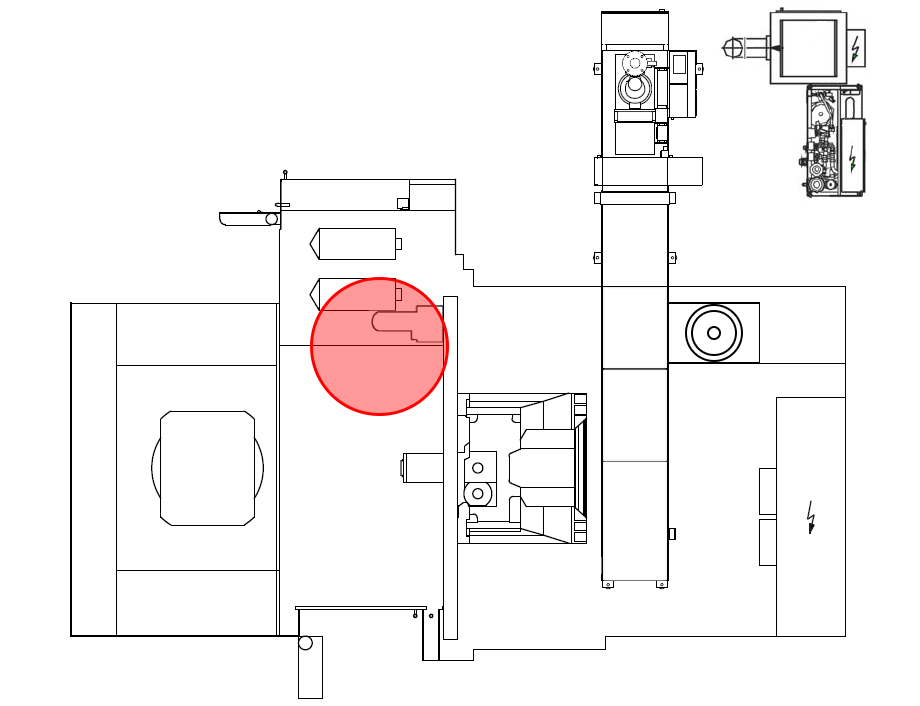

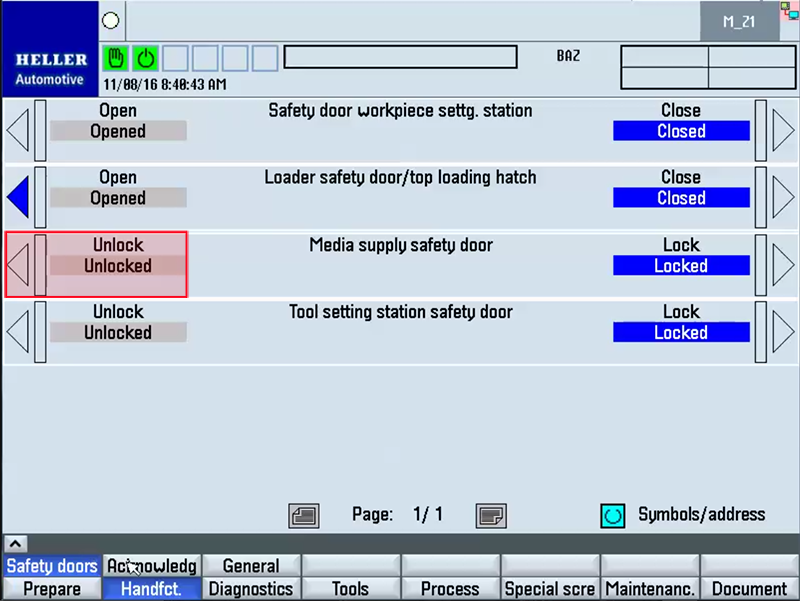

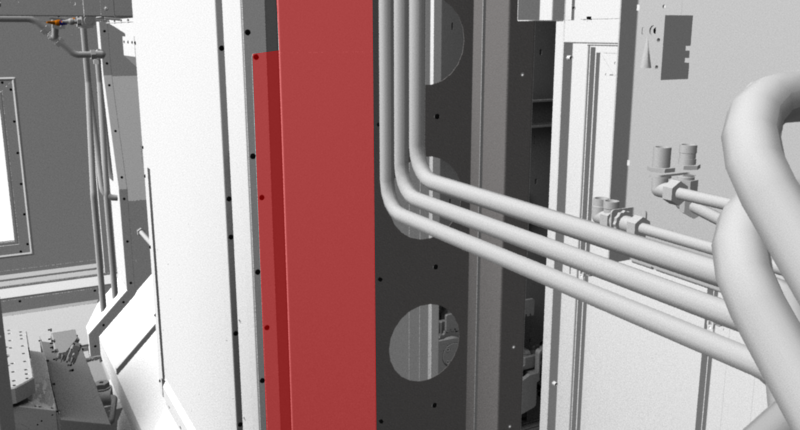

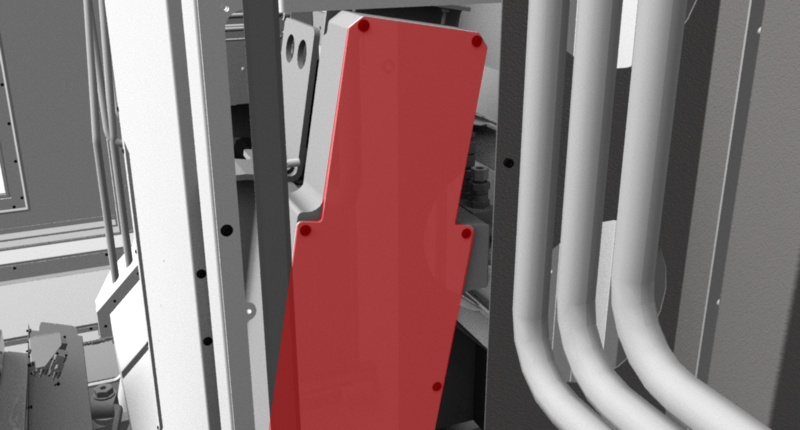

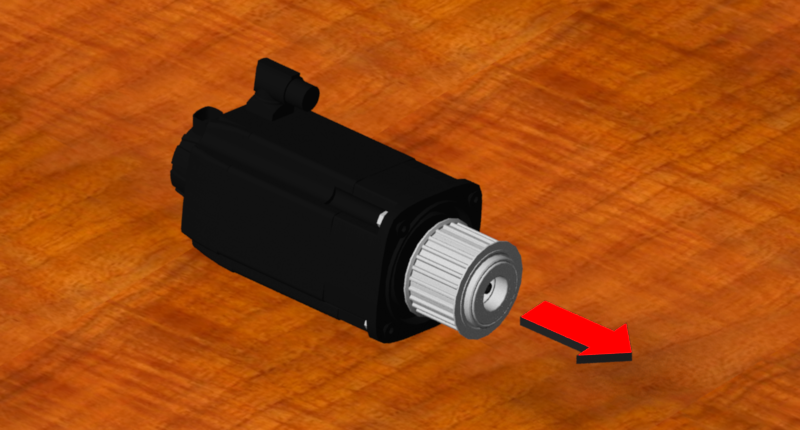

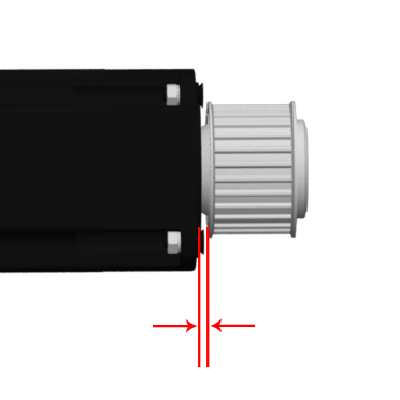

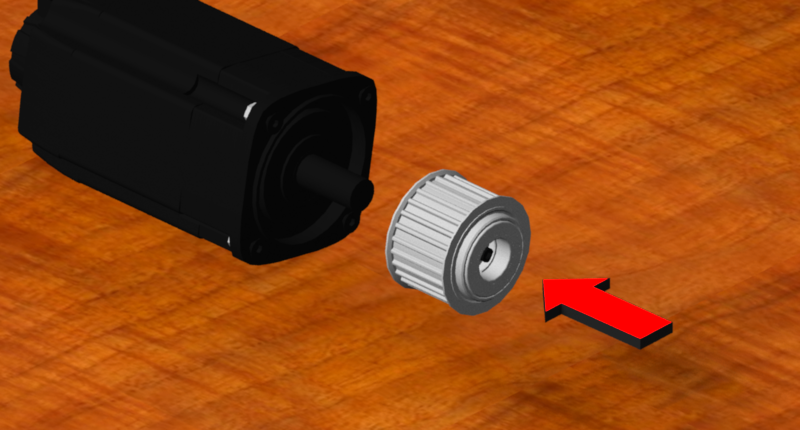

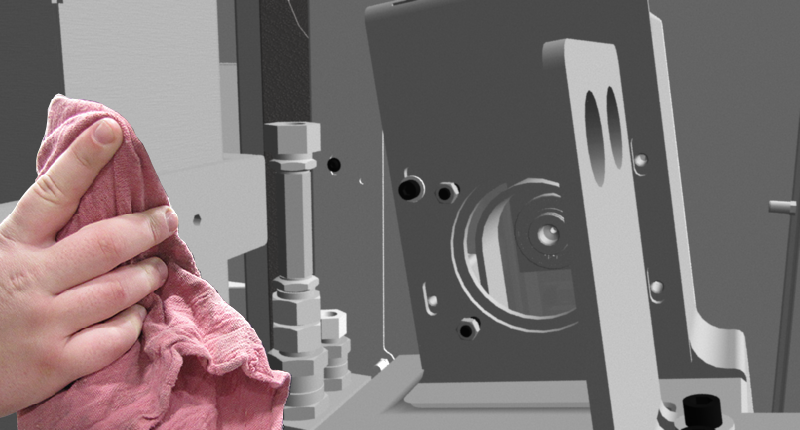

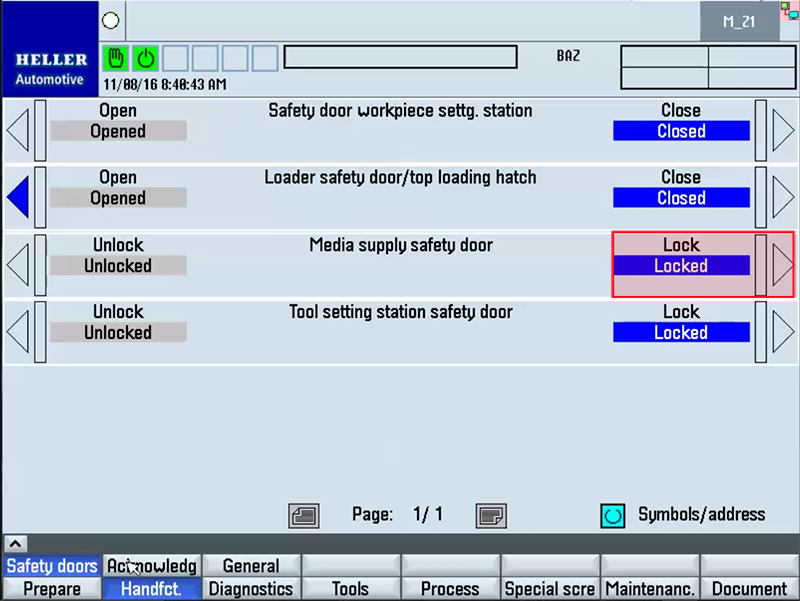

Step 1: ECPLStep 2: Open Maintenance DoorStep 3: Open Work Area Safety DoorStep 4: Open Concertina and Access PanelStep 5: Open Panel Above Tool Change DoorStep 6: Disconnect ServicesStep 7: Open Motor Maintenance panelsStep 8: Remove Adjustment BoltStep 9: Remove Lifting PlateStep 10: Loosen MotorStep 11: Lower MotorStep 12: Remove Counter BearingStep 13: Remove Plate and PulleyStep 14: Remove MotorStep 15: Check Depth / Remove Motor CouplingStep 16: Install Motor / Check DepthStep 17: Clean Mounting SurfacesStep 18: Install Motor (at lowest point)Step 19: Install BeltStep 20: Use Jack Bolt to Raise Motor UpStep 21: Install Motor ScrewsStep 22: Install Counter BearingStep 23: Install Adjustment BoltStep 24: Torque Motor ScrewsStep 25: Connect ServicesStep 26: Close Panel Above Tool Change DoorStep 27: Close Work Area Safety DoorStep 28: Close PanelsStep 29: Close Maintenance DoorStep 30: ECPLStep 31: Set Reference PointsSet the reference points for the ZT motor. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||