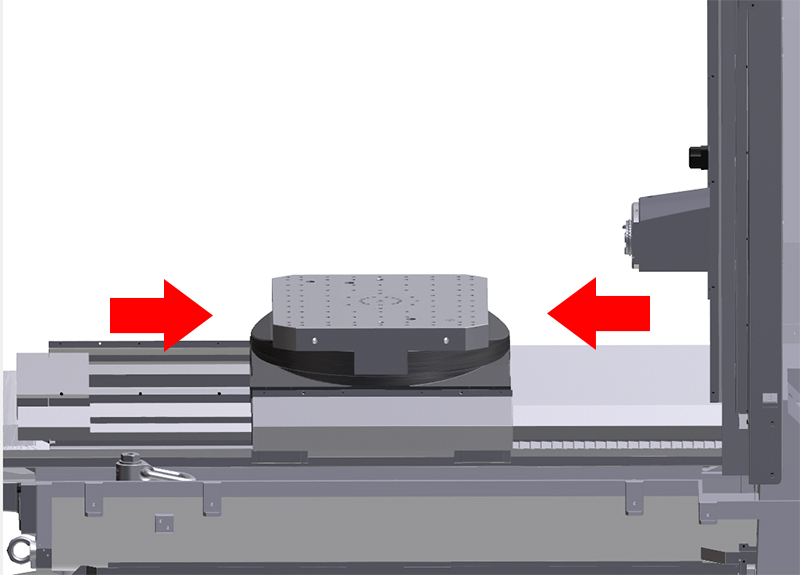

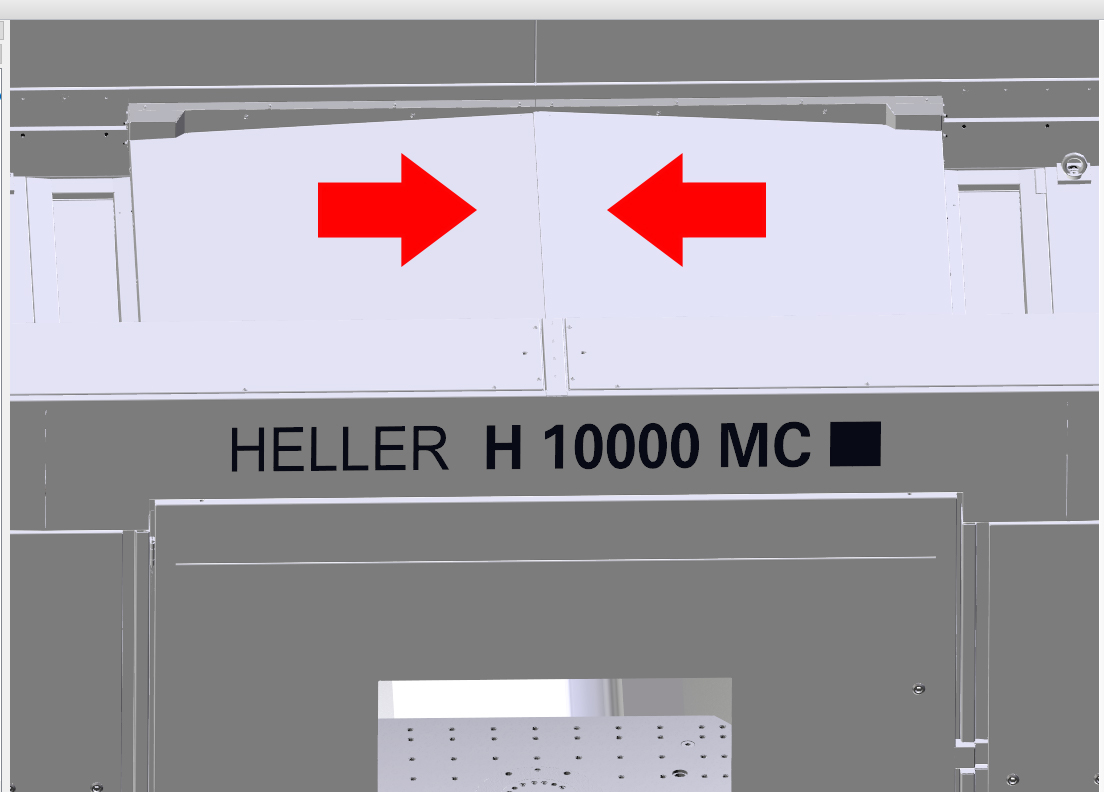

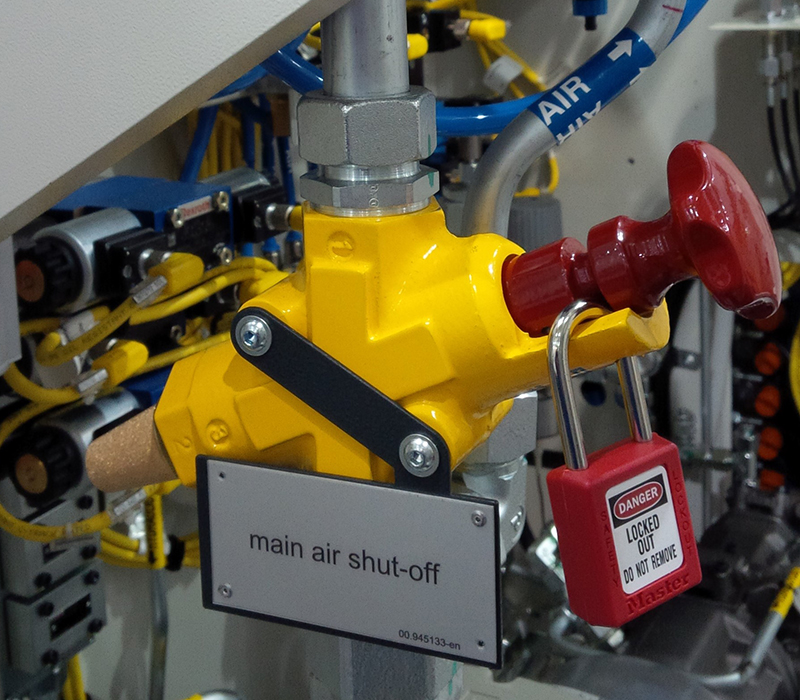

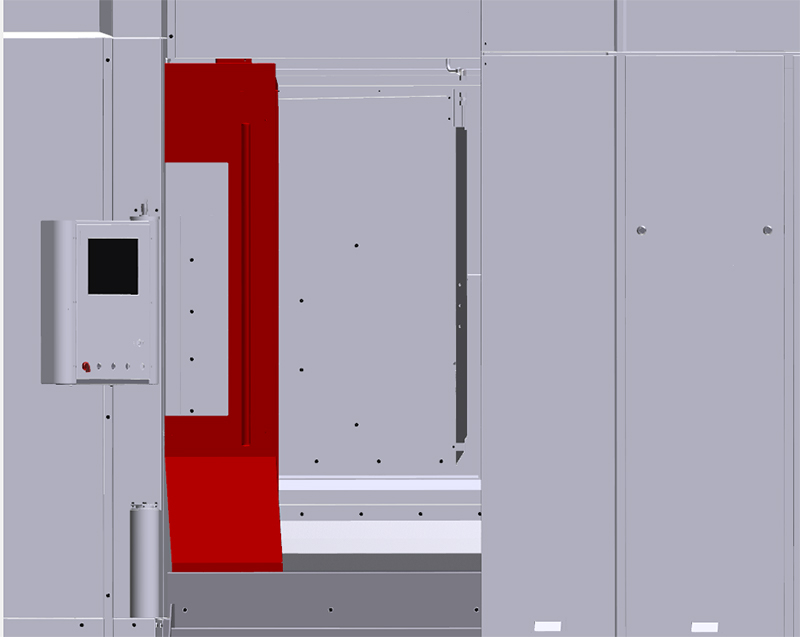

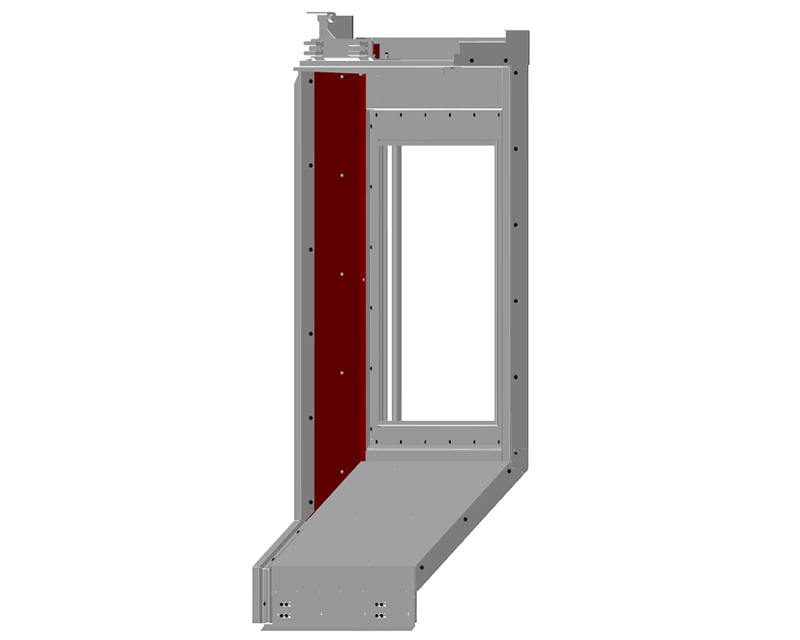

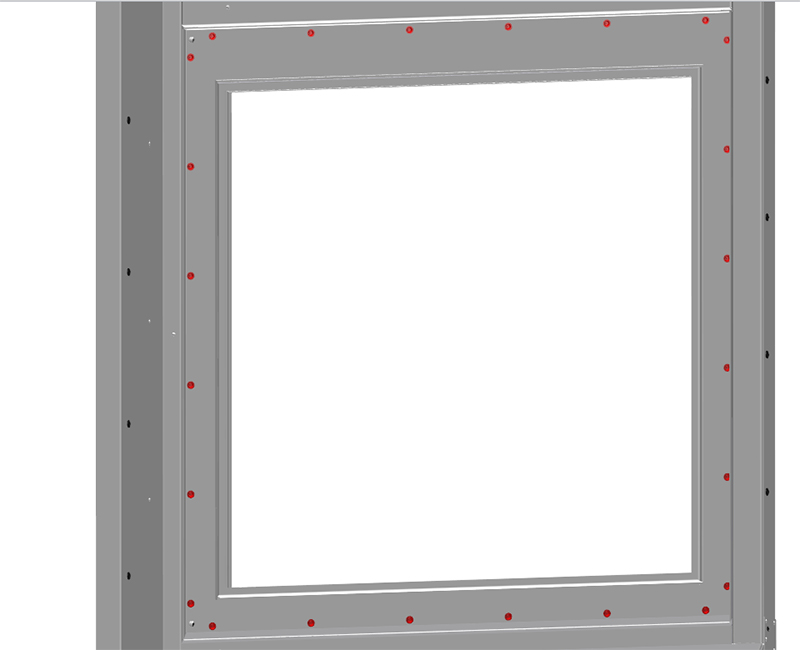

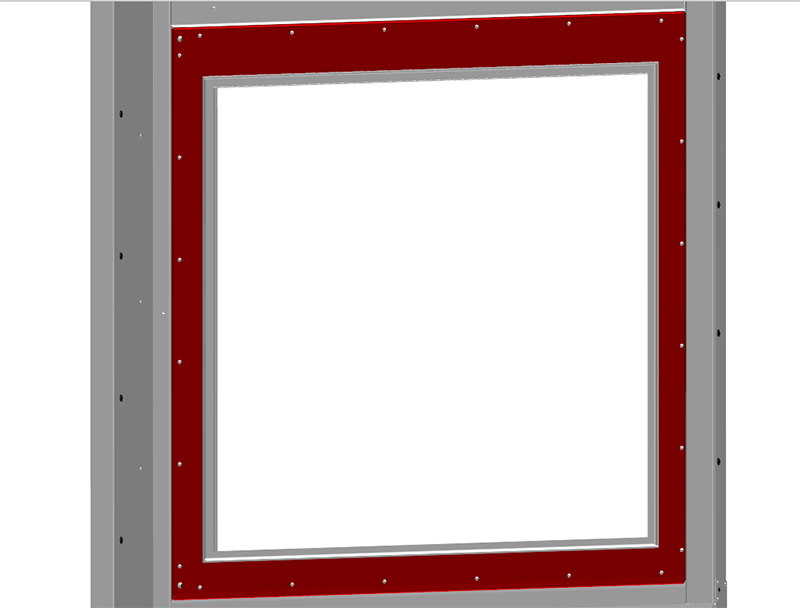

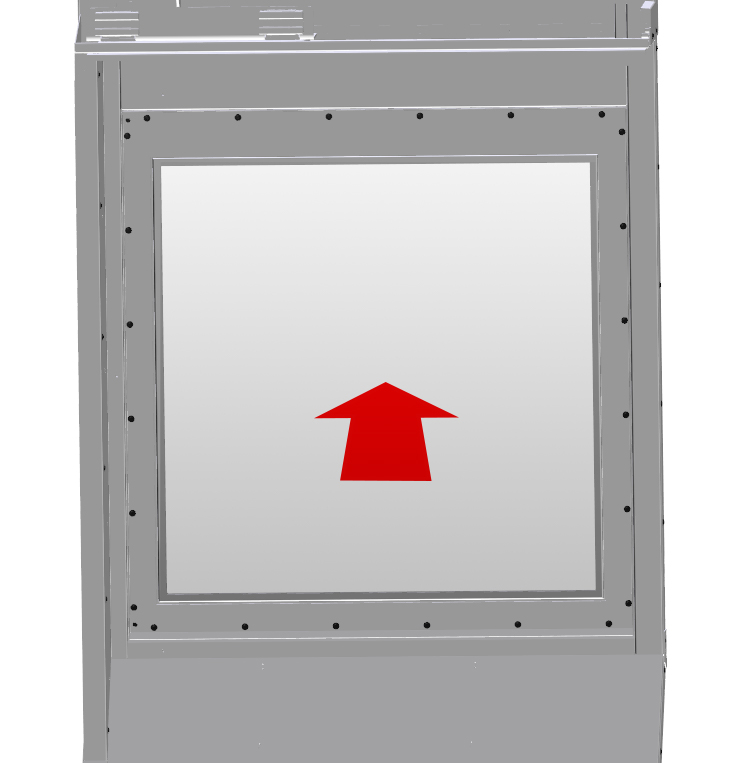

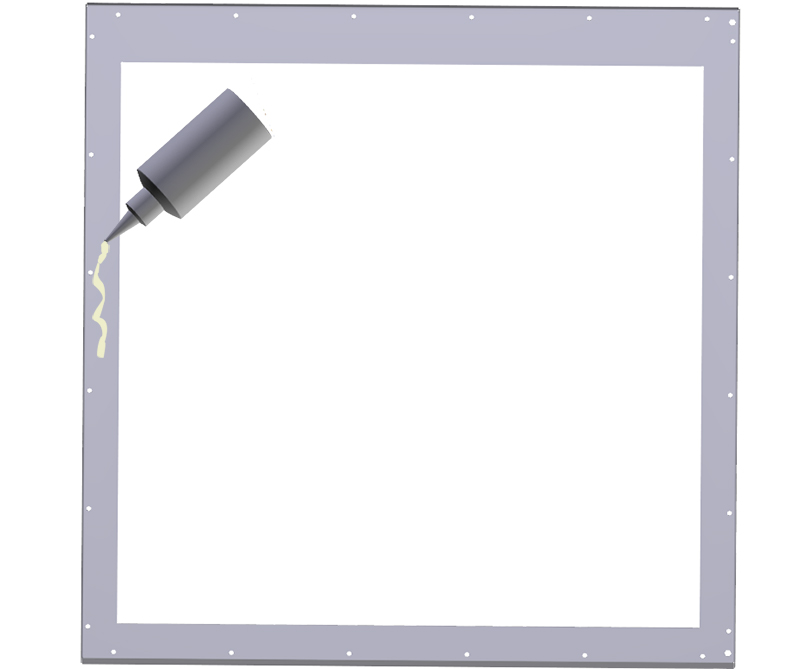

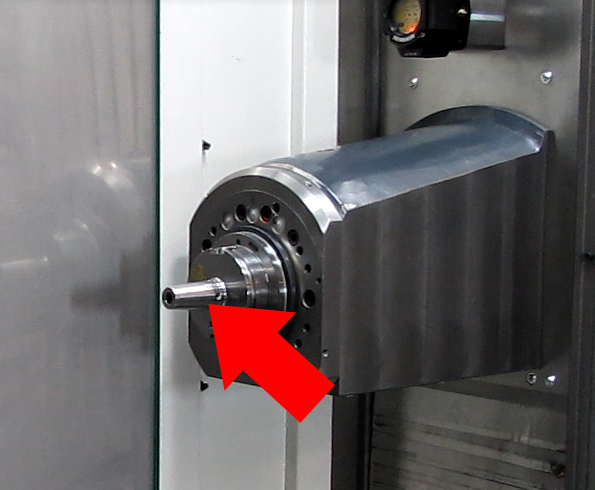

Replacing Safety Pane of the Work Area Safety DoorInterval 8 Year(s) Real time The safety pane consists of polycarbonate, which is protected on the inside by single-layer safety glass and on the outside by blown film. Polycarbonate can age and become brittle, which reduces its impact resistance. It is not possible to see this embrittlement! In order to protect persons in the machine surroundings, replace the safety pane after eight years as a precautionary measure. Component Safety pane of work area safety door Spare part Safety pane, Sealing strip, Joint sealant(Polyether to DIN 18454) See wearing and spare parts list (VS). Removing Safety PanePlease observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Exercise caution when working inside the machine with the machining unit not secured! Step 1:Step 2:The linear axes are positioned so as to make the inside of the work area safety door easily accessible.

Step 3:Step 4:Step 5:Step 6:Step 7:Unscrew cover plate to make the duct union of the air supply and all fixings of screen blow-off device accessible. Step 8:Step 9:Step 10:Step 11:Step 12:Installing Safety PaneStep 1:Step 2:Step 3:Step 4:Step 5:Connect the screen blow-off device to the air supply and fix to the retaining plate using retaining angles. Step 6:CloseStep 1:Before closing the work area safety door, ensure that nobody is behind the guard panels. Close work area safety door. Step 2:Step 3:Step 4:Step 5:Step 6: |