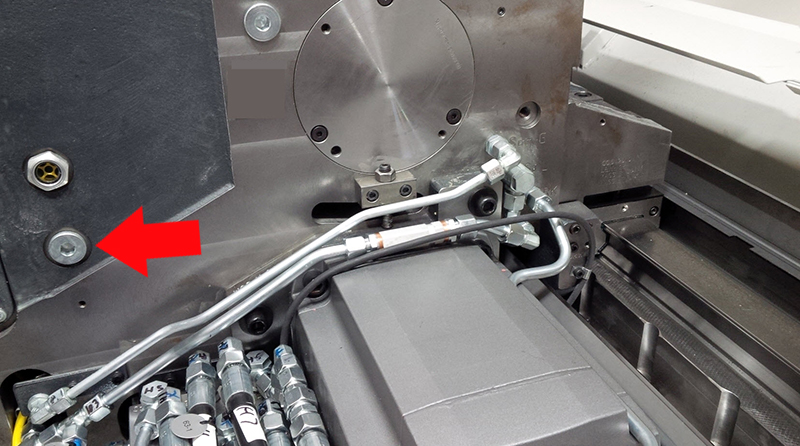

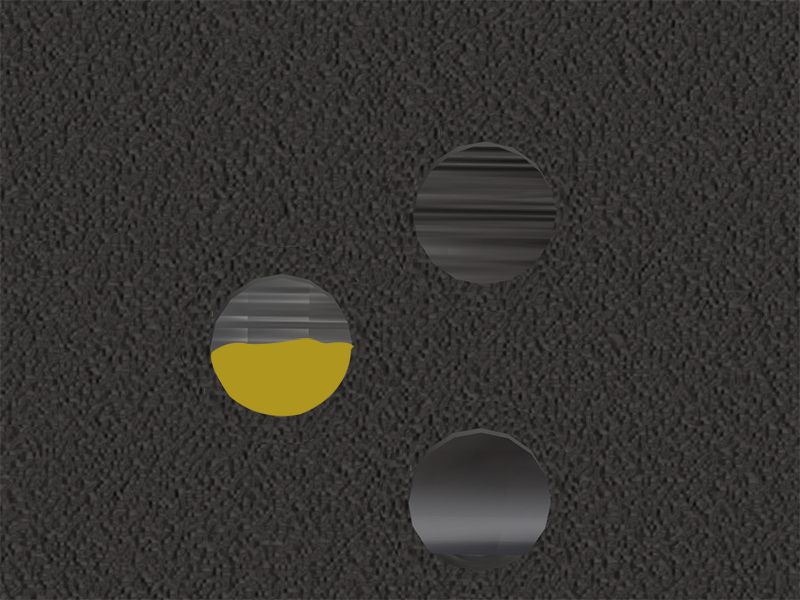

Oil Change in Rotary Feed TableInterval 1 Year(s) Real time Component Rotary feed table Consumable Lube oil SAE 80W GL-4 according to DIN 51502 Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. Used oil must be regarded as hazardous waste and be disposed of according to the locally applicable regulations. Spare part Oil filler screw or oil drain screw with seal: screw plug See wearing and spare parts list.

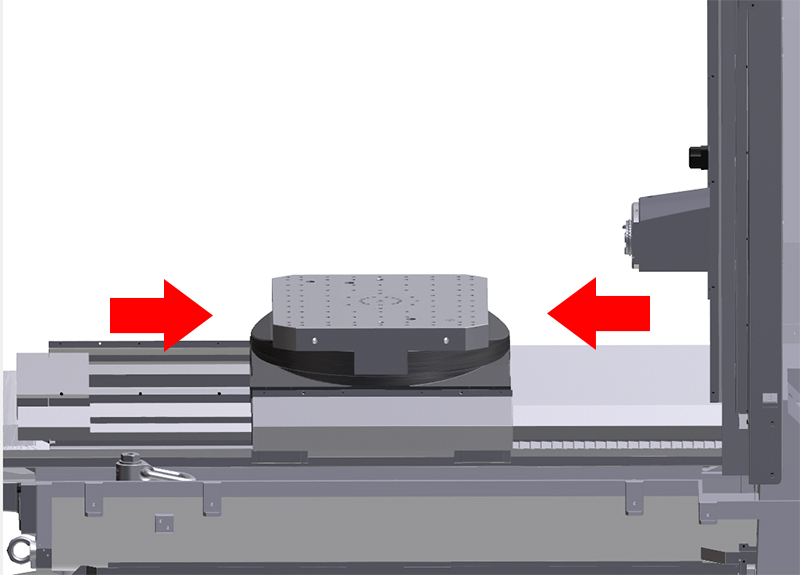

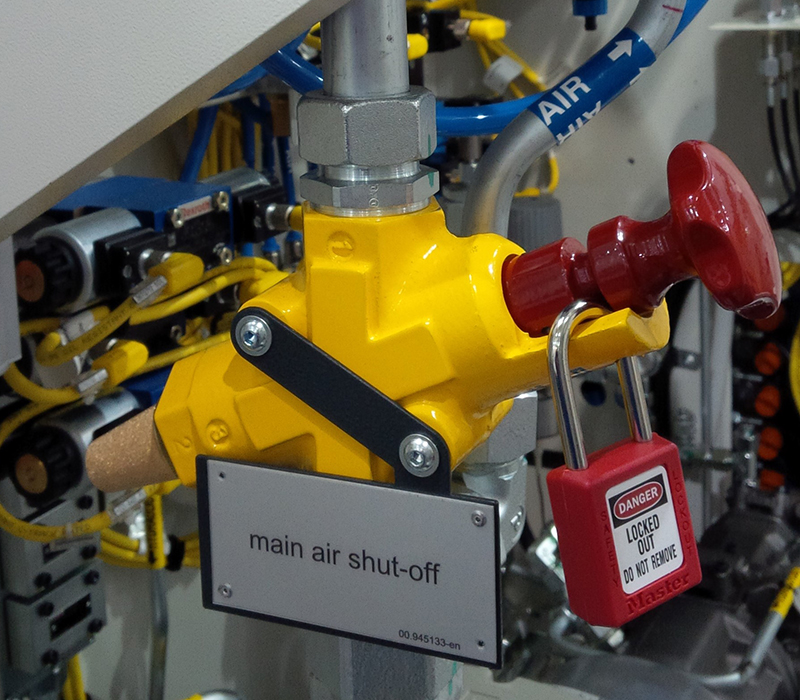

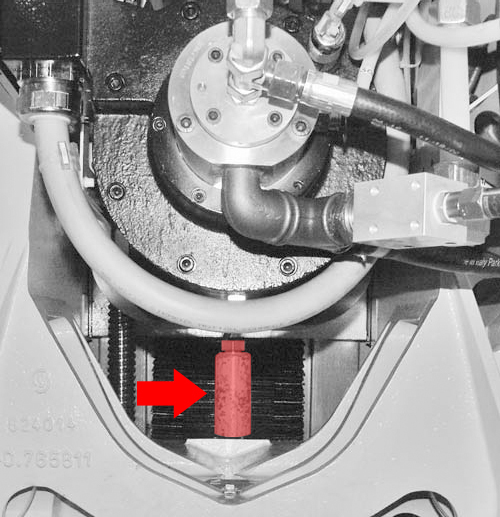

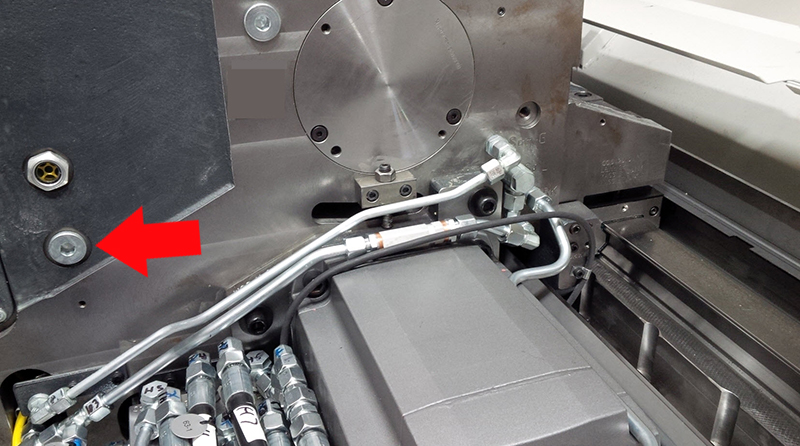

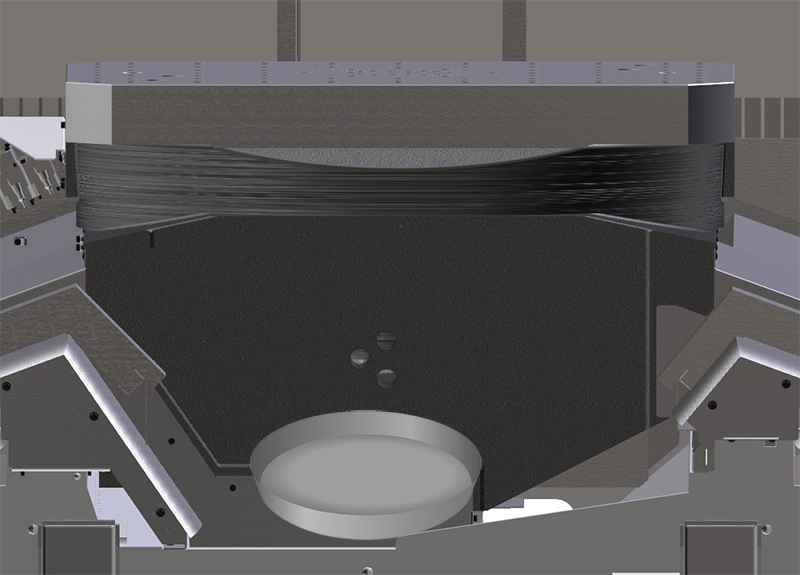

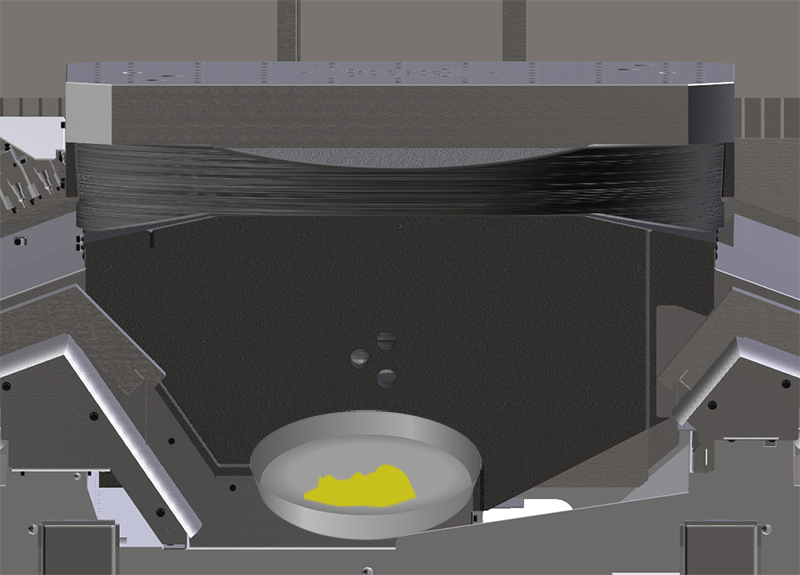

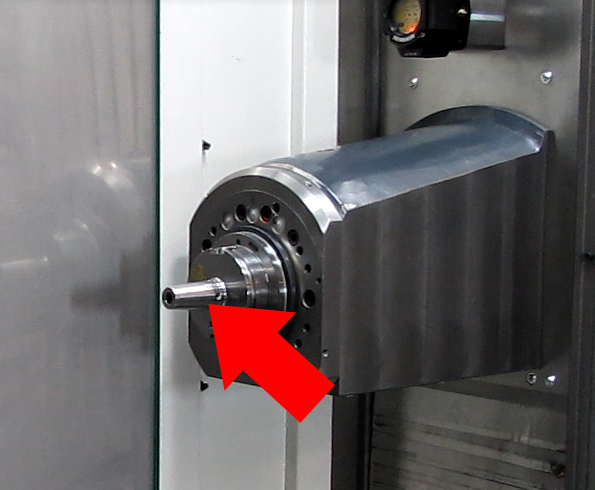

Procedure Please observe "Special safety measures" when entering or leaving the machine. Exercise caution when working inside the machine with the machining unit not secured! Step 1:The rotary feed table is warm to the touch. Step 2:Step 3:The linear axes are positioned so as to make the rotary table easily accessible.

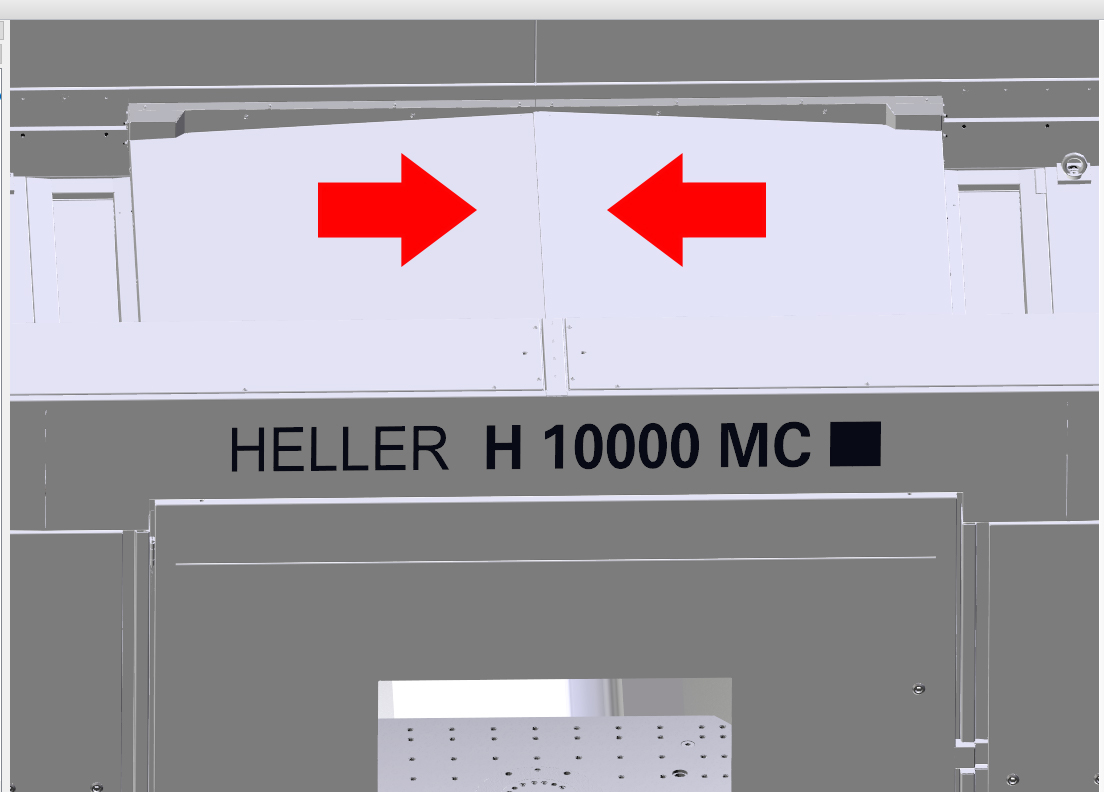

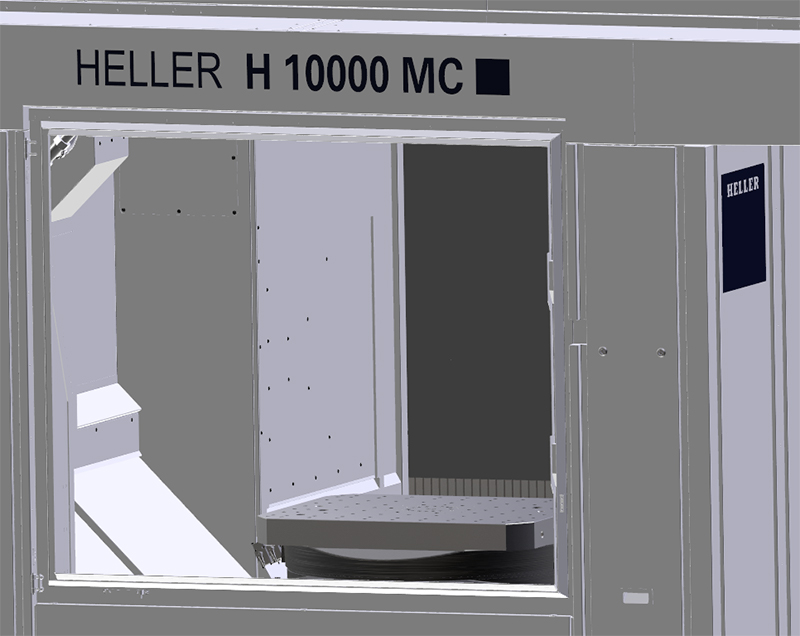

Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Step 12:Step 13:Step 14:Step 15:Step 16:Before closing the safety door, ensure that nobody is behind the guard panels. Close workpiece setting station safety door (front door). Step 17:Step 18:Before closing the safety door, ensure that nobody is behind the guard panels. Close maintenance area safety door. Step 19:Step 20:Step 21:Step 22:Step 23: |