Checking Tool Holder Blow-offInterval Component

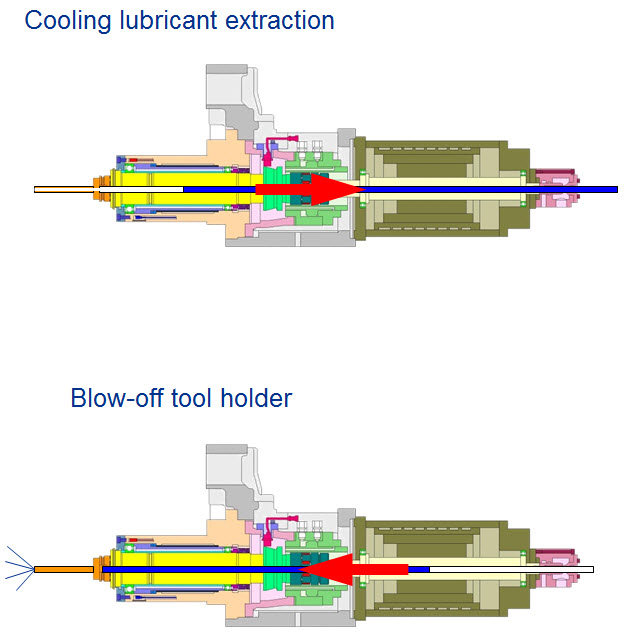

50 Hours Operating time Tool Spindle The tool holding fixture is cleaned in two stages during the tool change operation:

A malfunctioning extraction device is indicated by an increased volume of cooling lubricant being drawn into the tool magazine. Problems with clamping the tool into the tool spindle or reduced machining accuracy indicate inadequate blow-off. Procedure The machining program runs in automatic mode. Check wither the tool holding fixture is effectively blown off during a tool change cycle.

In the absence of an air flow, check air supply to the tool spindle.

For procedure see: |