Replacing drive motor

Parts List

Reference Files

Tools Required

Torque Chart

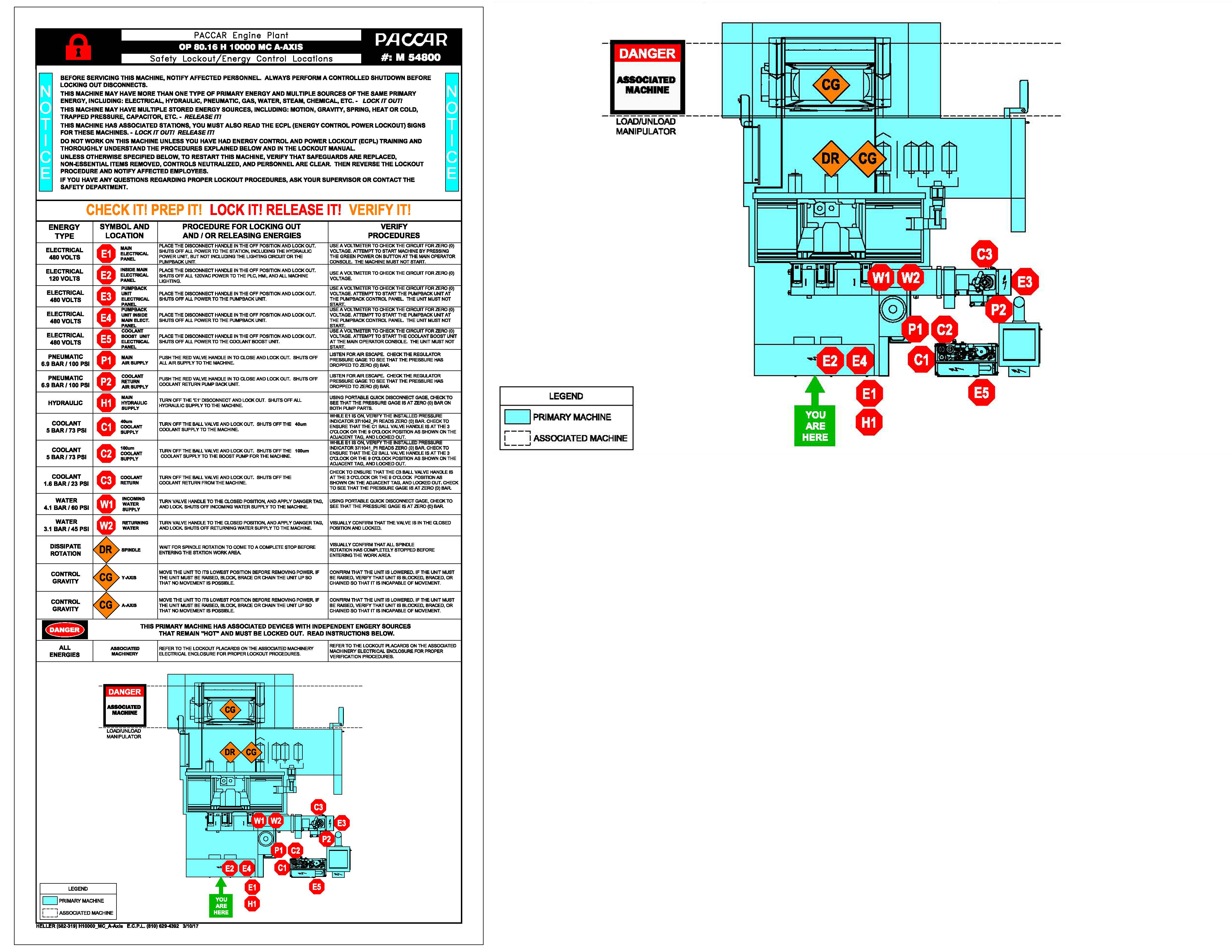

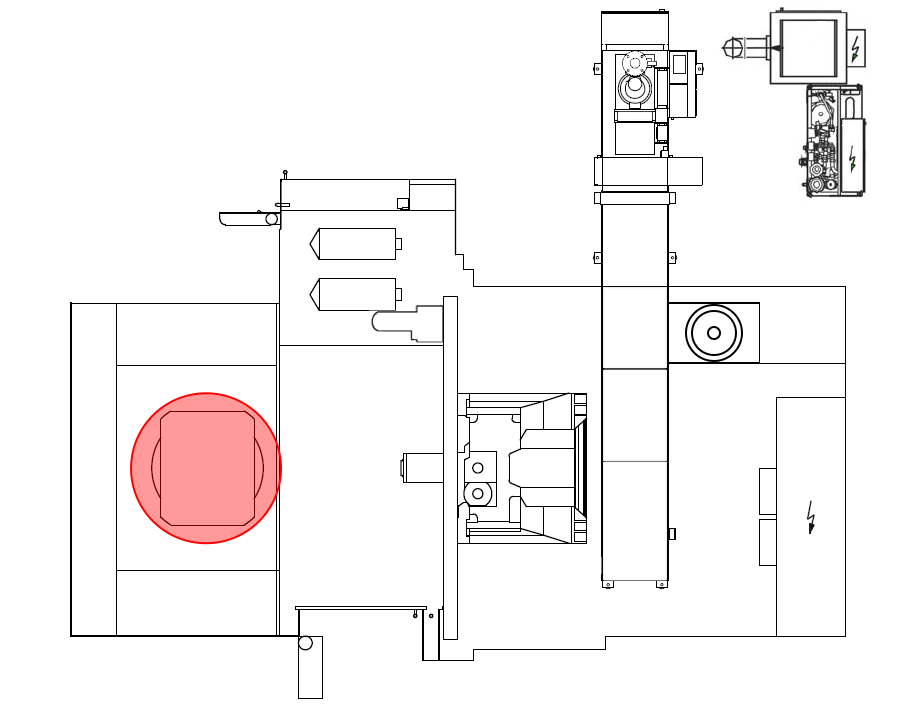

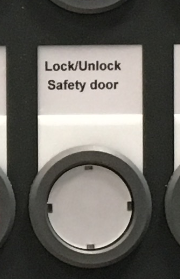

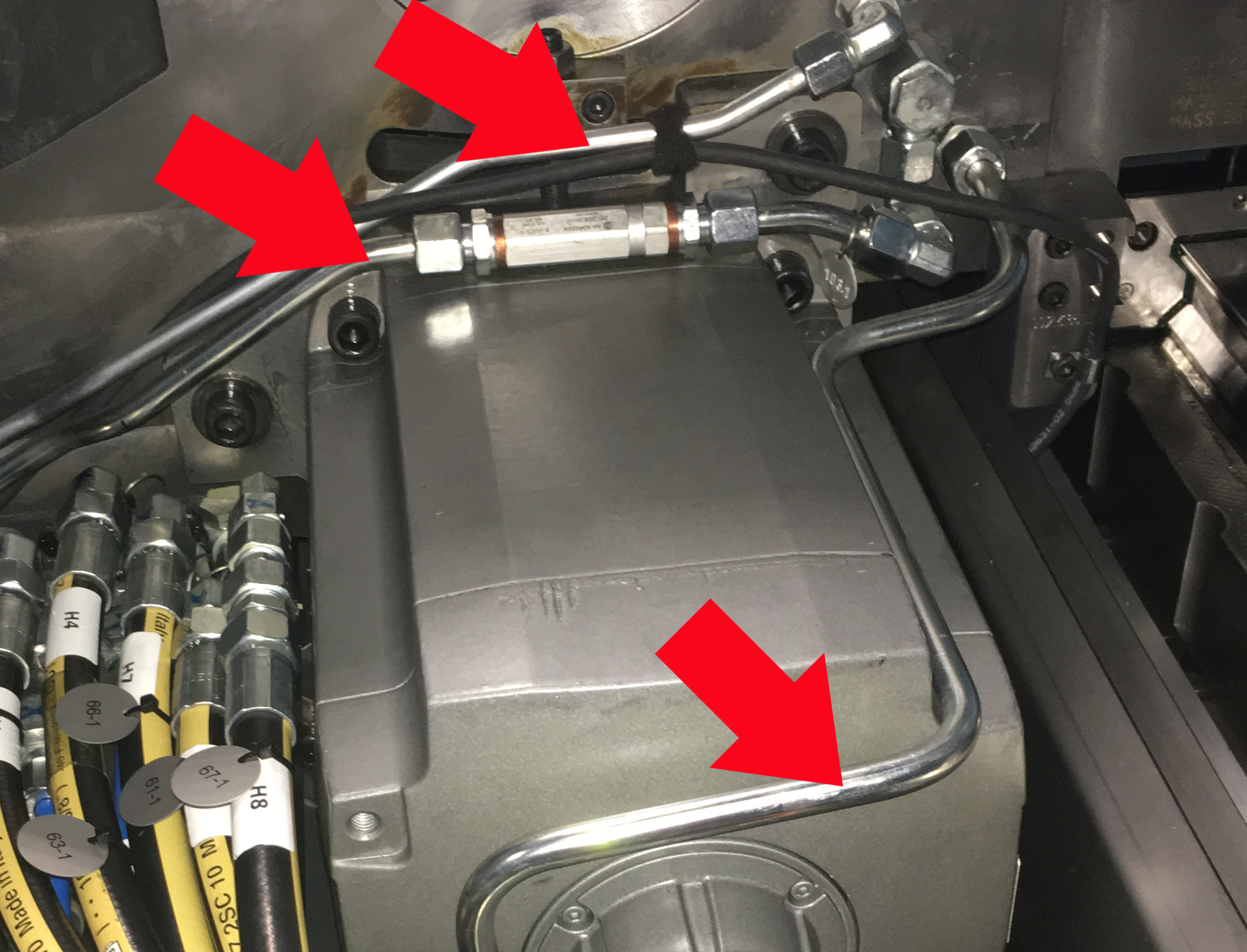

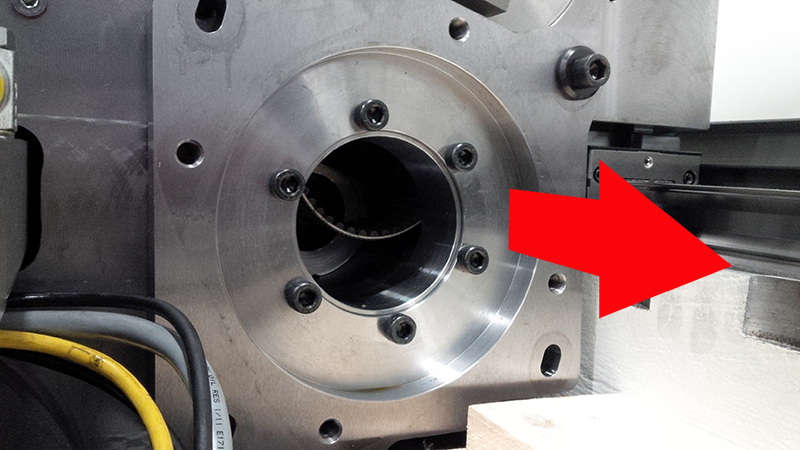

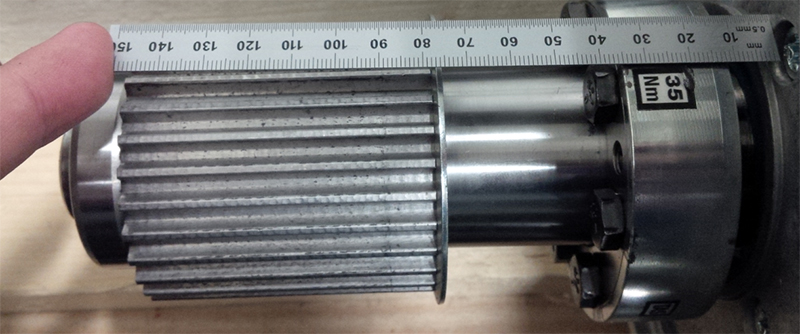

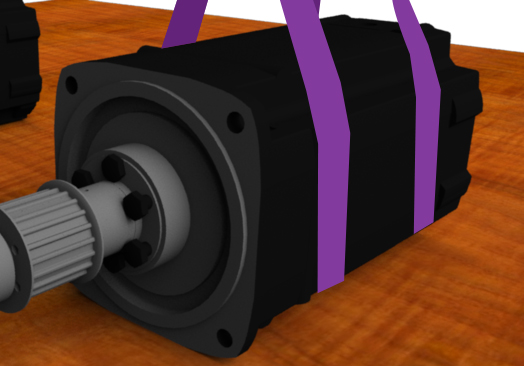

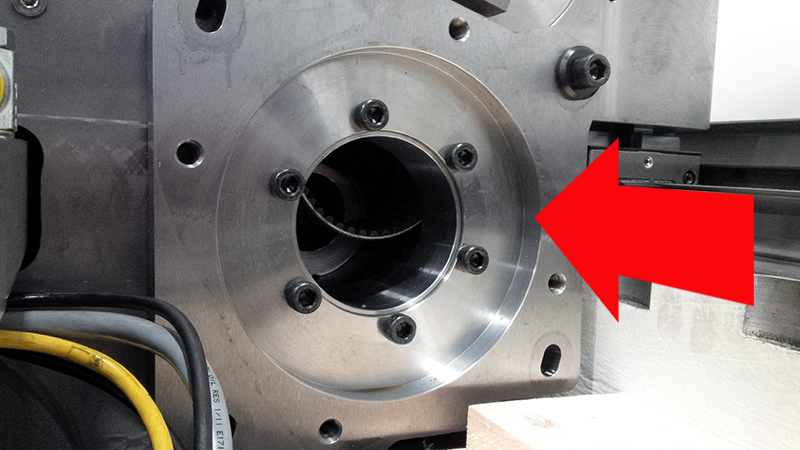

Step 1: ECPLStep 2: Jog Z-Axis in Positive DirectionStep 3: Open Work Area Safety DoorStep 4: Remove Z-Axis Concertina CoverStep 5: Loosen Belt Tension NutStep 6: Disconnect Motor CablesStep 7: Disconnect Motor LinesStep 8: Loosen Motor Housing ScrewsStep 9: Remove Motor ScrewsStep 10: Remove MotorStep 11: Remove Belt Access PlateStep 12: Measure Motor Flange / CouplingStep 13: Loosen BoltsStep 14: Separate CouplingStep 15: Install Coupling on New MotorStep 16: Measure Motor Flange / CouplingStep 17: Install Bolts into CouplingStep 18: Secure Motor with AssistStep 19: Install MotorStep 20: Install Motor ScrewsStep 21: Install Belt Tension NutStep 22: Tighten Motor Housing ScrewsStep 23: Reinstall Belt Access PlateStep 24: Reconnect Motor CablesStep 25: Reconnect Motor LinesStep 26: Reinstall Concertina CoverStep 27: Close Work Area Safety DoorStep 28: ECPL |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||