Changing Cooling Water in Cooling Unit

The container in the cooling unit holds 42 l. You therefore require approx. 27 litres of water and 15 litres of Antifrogen N. HELLER item number 49.200333 will give you coolant water as a prepared mixture. Handling demineralised water and auxiliary materials:

Safety precautions for Antifrogen N:

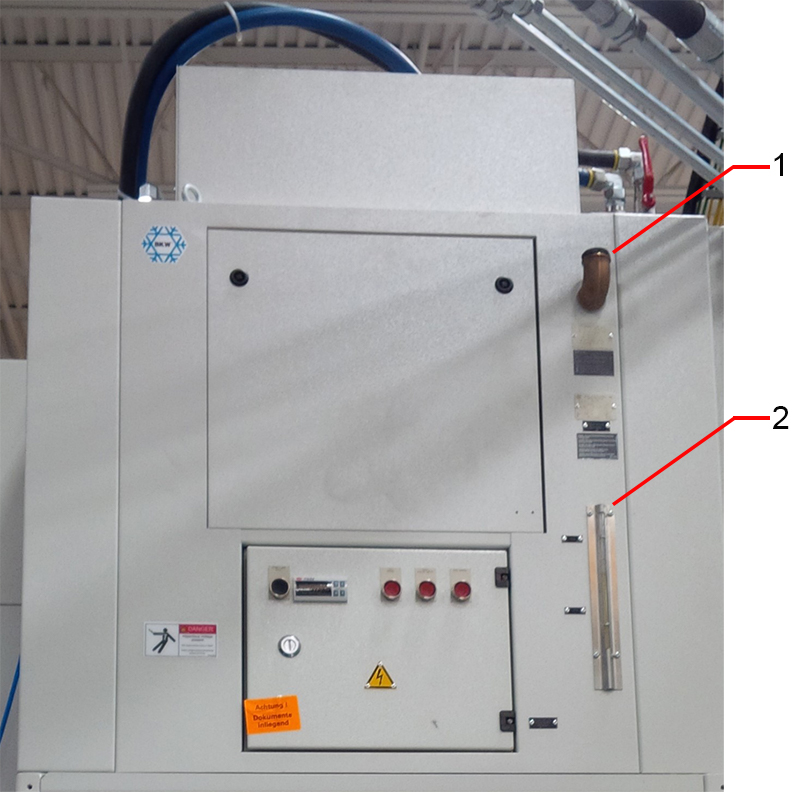

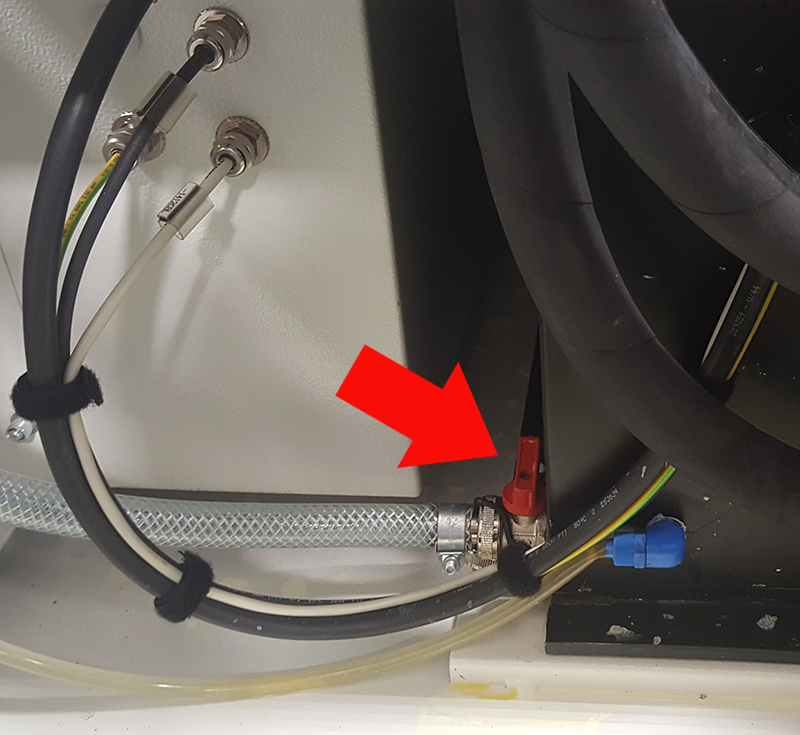

Furthermore, observe the safety instructions on the product packaging. Ladder, Container for collecting used cooling and rinsing water Drinking water for rinsing the cooling circuit, Clean vessel for preparing the mixture, Clean equipment for filling (jug, funnel) For manufacturer's documentation on the cooling unit, see Subsuppliers' Information (ZI) from "Clariant". For structure of the cooling unit, see the cooling water diagram. Dispose of the used cooling water according to the locally applicable regulations. Draining Cooling WaterStep 1:Step 2:Machine switched off at main switch and secured against being switched on again. This switches off the cooling unit. Step 3:Step 4:Step 5:Step 6:Step 7:Before closing the maintenance safety door, ensure that nobody is behind the guard panels. Close maintenance area safety door. Filling with Flushing Water and Purging Cooling CircuitUse pure drinking water as flushing water. Step 1:Fill with flushing water through the filling opening up to the maximum mark on the filling level indicator.

Step 2:Switch on machine at main switch and wait approx. 5 minutes. The cooling unit is running, the cooling circuit is vented. Step 3:Check level at the filling level indicator. Top up flushing water to maximum mark.

Step 4:Step 5:Draining Flushing WaterStep 1:Step 2:Machine switched off at main switch and secured against being switched on again. This switches off the cooling unit. Step 3:Step 4:Step 5:Step 6:Step 7:Before closing the maintenance safety door, ensure that nobody is behind the guard panels. Close maintenance area safety door. Filing with Cooling WaterDo not allow the machine to stand empty after flushing, refill with cooling water immediately. Use only freshly prepared mixtures with reference ratio 65:35 percent by volume. Do not add the constituents separately, prepare the mixture beforehand. Step 1:Fill with cooling water through the filling opening up to the maximum mark on the filling level indicator.

Step 2:Switch on machine at main switch and wait approx. 5 minutes. The cooling unit is running, the cooling circuit is vented. Step 3:Check level at the filling level indicator. Top up with cooling water to maximum mark.

Step 4: |

||||||||||||||||||||||||||||||||||||