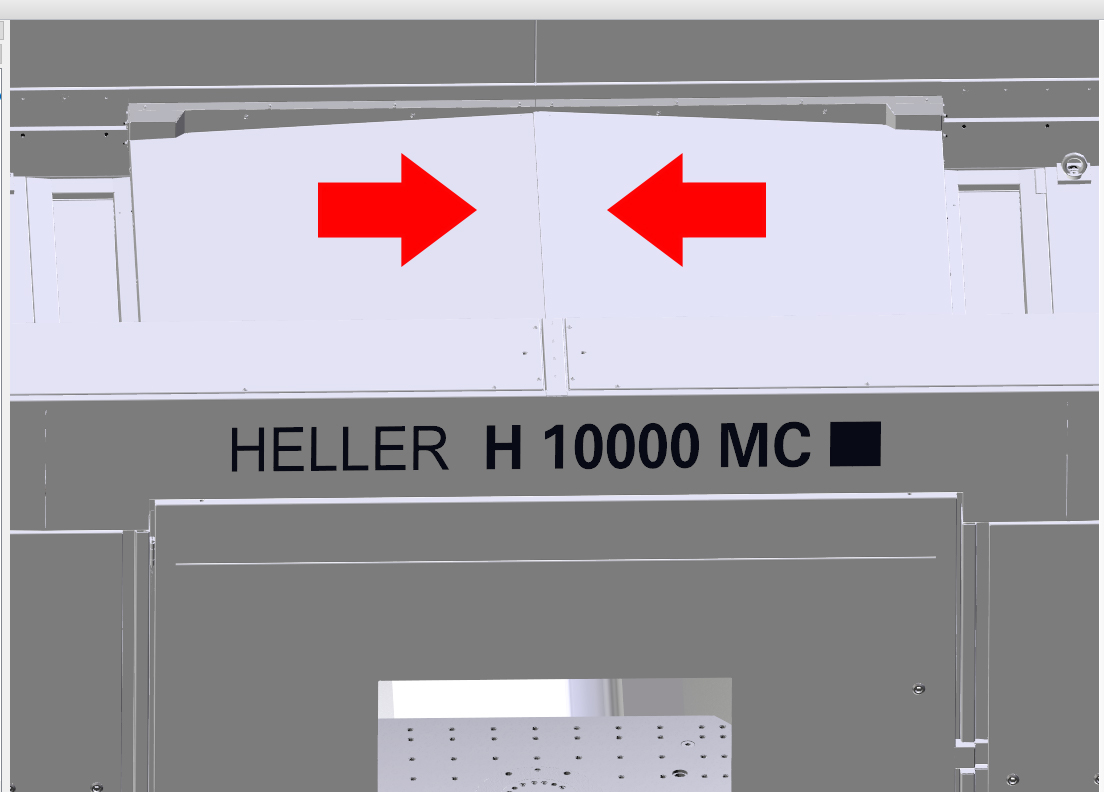

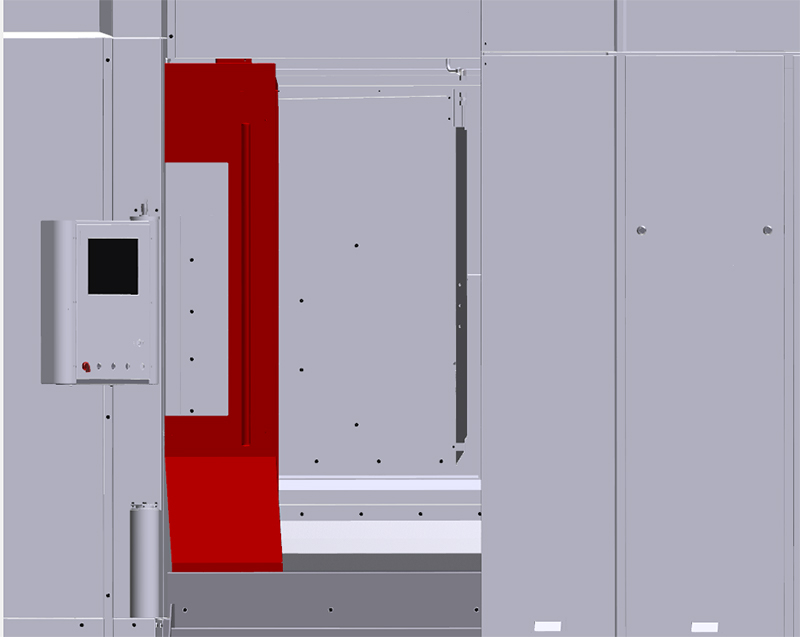

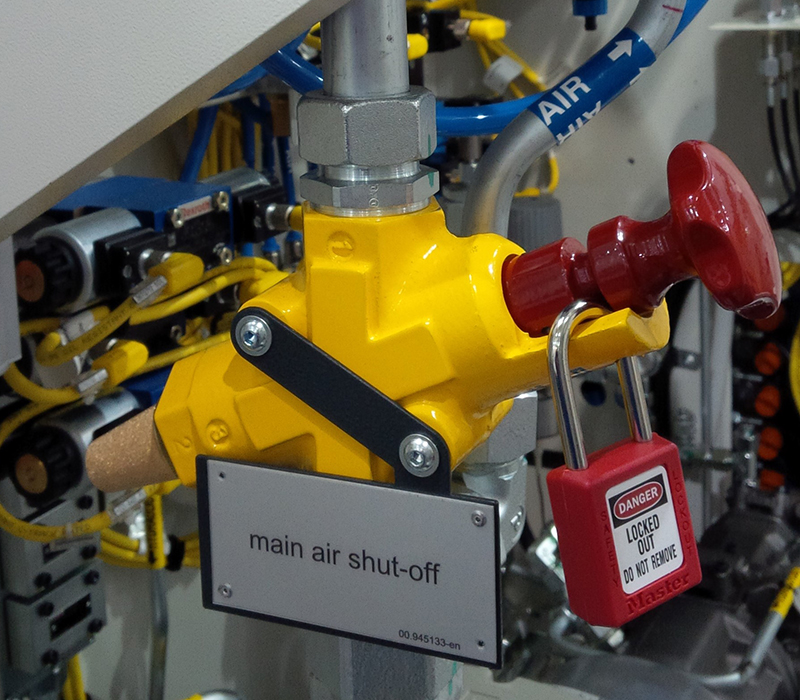

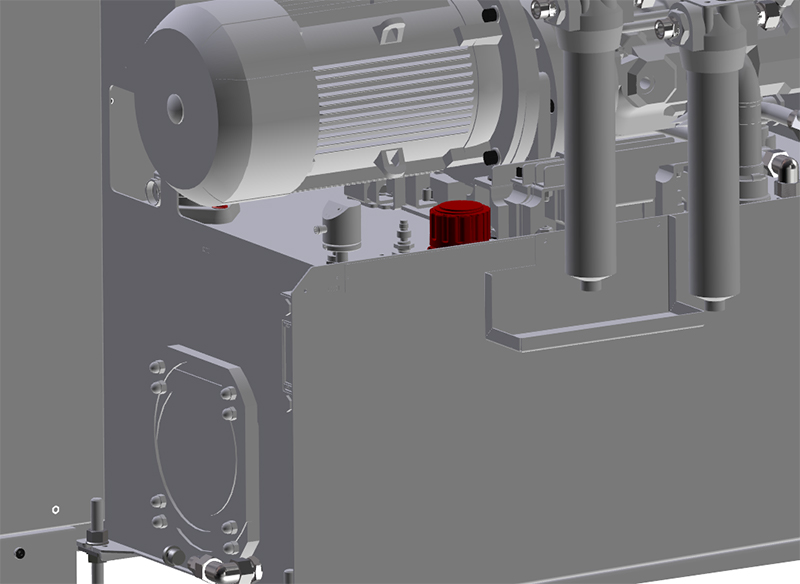

Hydraulic Oil Fill Level Pre-warningComponent Hydraulic unit Action Check hydraulic equipment for tightness, replenish oil The hydraulic cycle is a closed system where only little of the hydraulic oil may be lost through leakage. Substantial oil loss indicates leakage. Leakage oil can damage your equipment and the environment. Consumable Hydraulic oil HLP 46 to DIN 51524, Part 2 (ISO-L-HM 46 to ISO 6743, Part 4) Purity class ISO 4406-18/16/13 Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. For structure of the hydraulic system, see media diagram (MP). Inspection of Hydraulic EquipmentPlease observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Danger to life within the traversing range of the gantry loader. Before climbing onto the machine, always move the portal loader to its parking position, switch off and secure to prevent it being switched on again. Do not remove gantry loader padlock before end of work or before removing the ladder. Proceed with caution if a tool is placed in the tool spindle whilst you are working within the work area. Step 1:Step 2:Loading hatch closed. Gantry loader in parking position, switched off and secured against being switched on again. Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Check all equipment components for leakages and visible external damage:

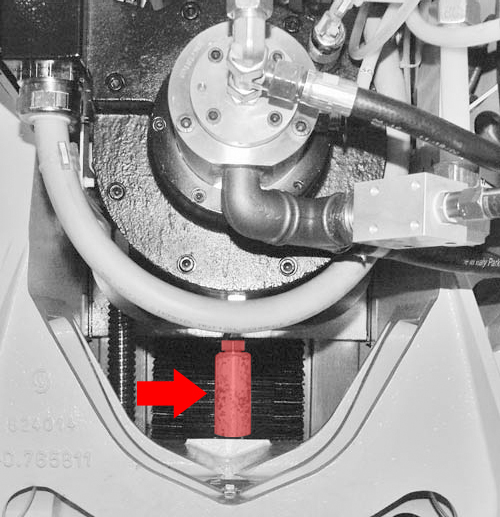

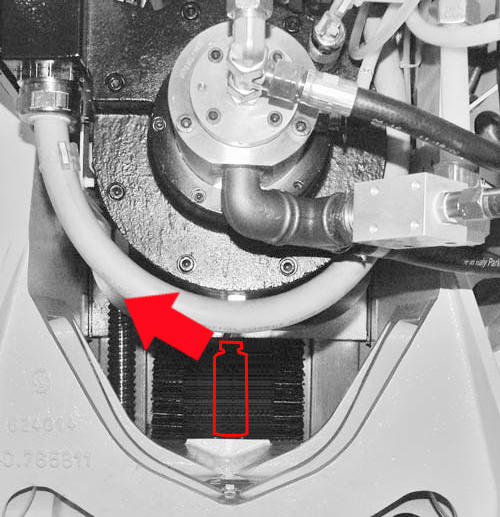

Repair leakages and damage immediately. Do not operate machine with damaged equipment! Step 9:Remove support from the machining unit. Before closing the maintenance openings and safety doors, ensure that nobody is behind the guard panels and doors. Close maintenance openings and safety doors. Step 10:Filling oilStep 1:Step 2:Fill with oil through filling opening in filler filter up to the max. mark on the oil level indicator. Step 3:Step 4:Step 5:Step 6:Run machine for a few minutes. Check hydraulic reservoir for leakage. Step 7:Step 8: |