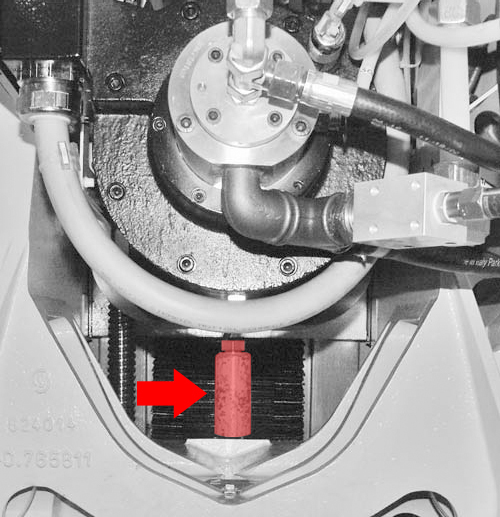

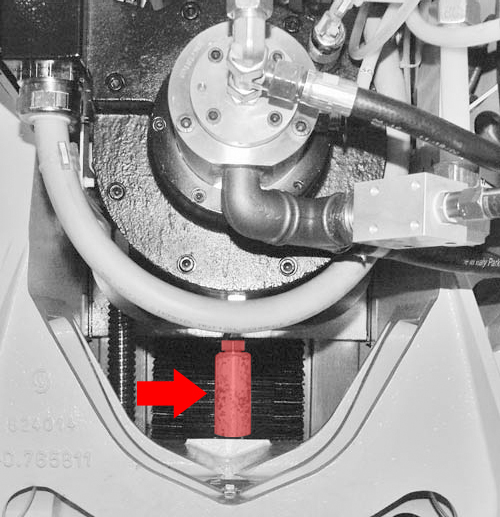

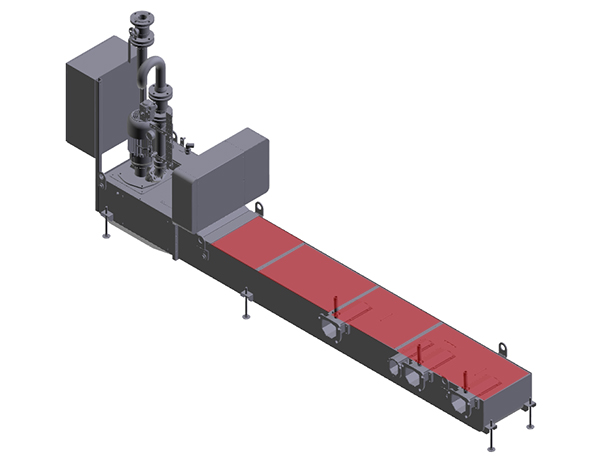

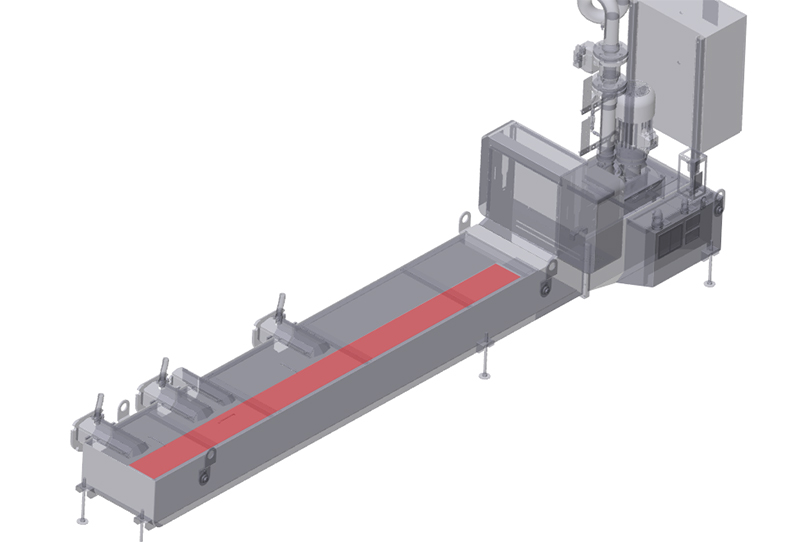

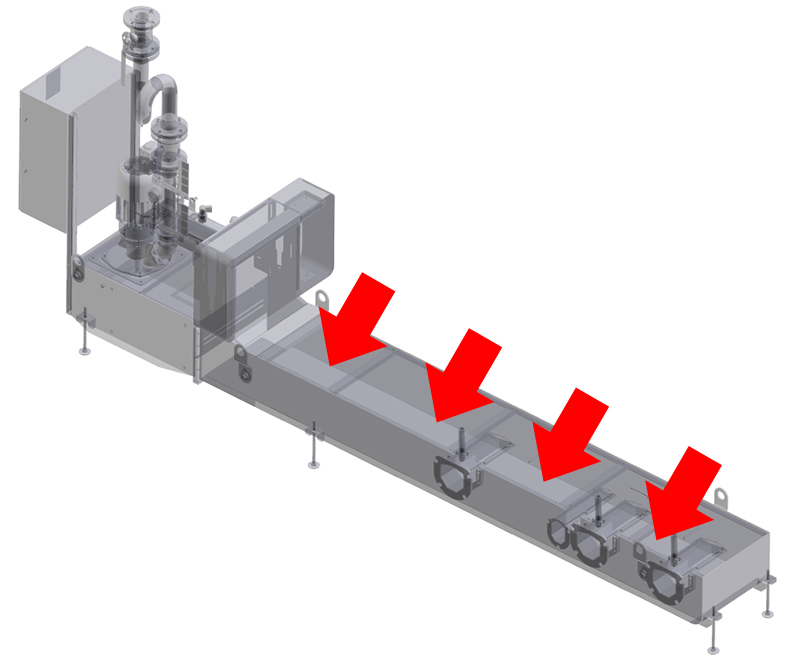

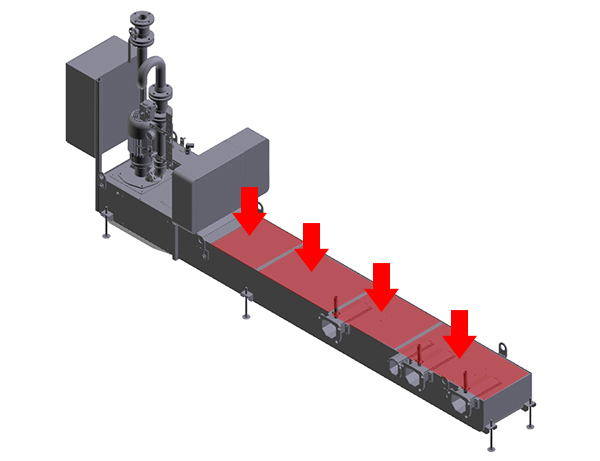

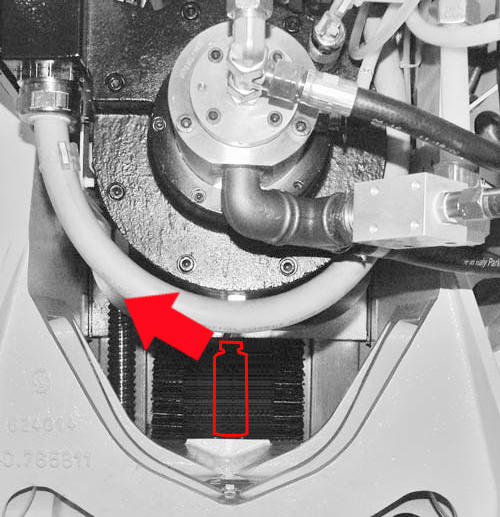

Clean and Check Chip ConveyorInterval 1 Year(s) Operating time Reduce this interval depending on the contamination of the machine. Component Chip Conveyor Exhauster unit to exhaust cooling lubricant and sludge For manufacturer's documentation on the chip conveyor, see Subsuppliers' Information (ZI) from "Knoll". Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Step 11:Step 12:Step 13: |