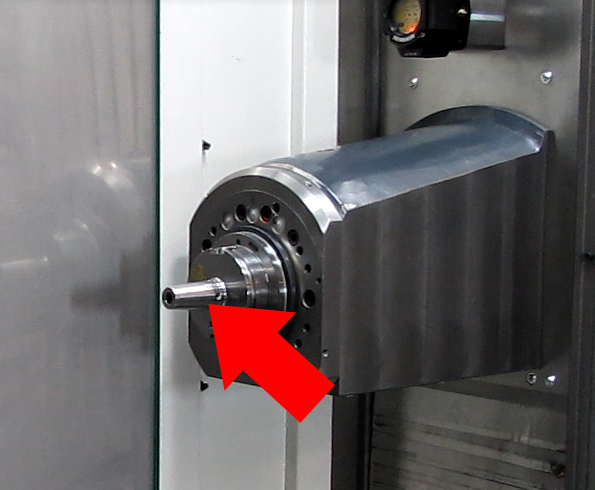

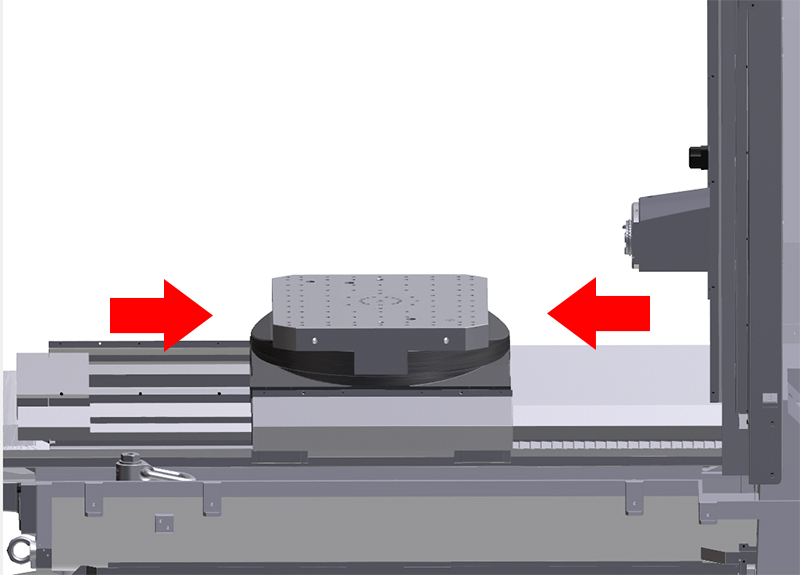

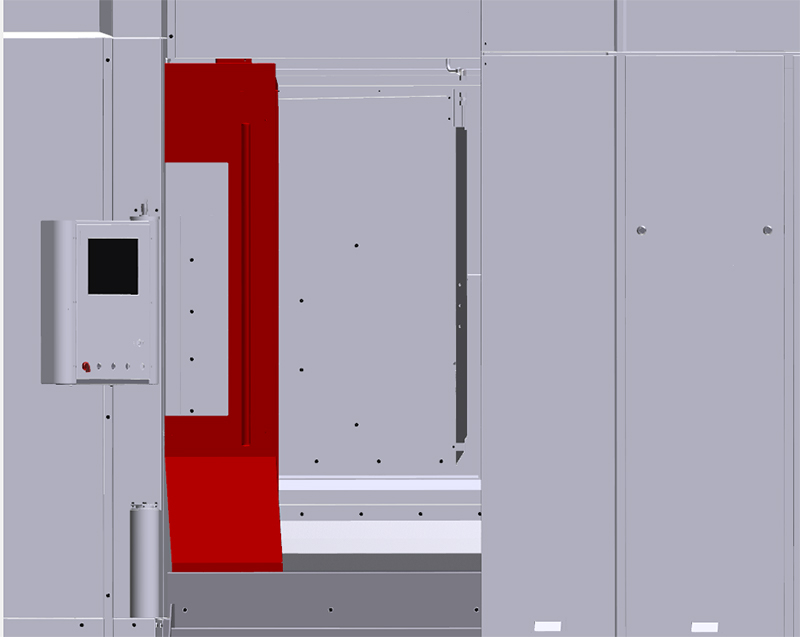

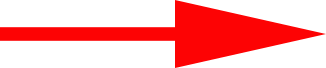

Check Tool Pull-in ForceMeasuring device, for example model "Power-Check" by Ott-Jakob Slot-type screwdriver, width 5.5 mm The collet features a latch which holds the measuring device even in the "unclamped" position. For safety reasons, it is nonetheless advisable to hold the measuring device in place during opening the collet. The collet engages easily, but it has a high retaining force, so you need a screwdriver as leverage to remove the measuring device. PreparationStep 1:Step 2:The machining unit is positioned such that you can work on the tool spindle and read-off the measuring device display without entering the work area.

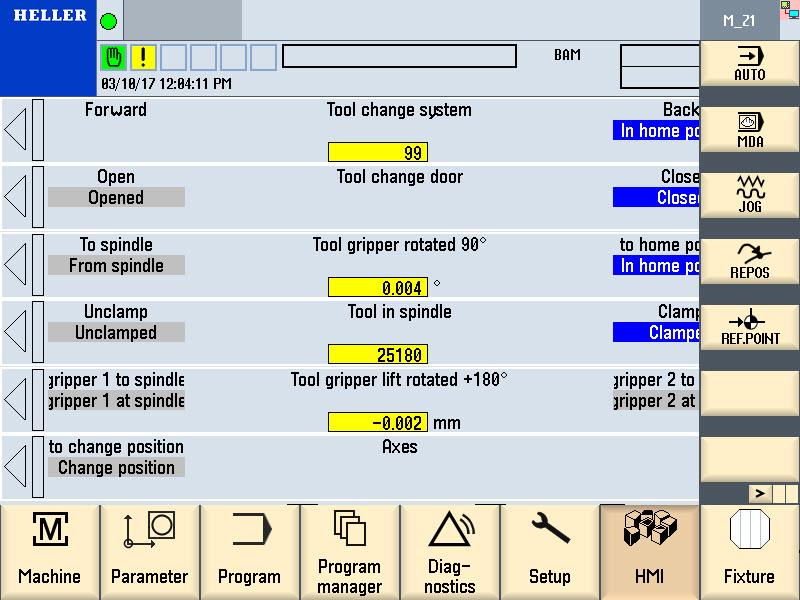

Step 3:Step 4:Step 5:Take hold of the tool inserted into the tool spindle. Unclamp tool. You can use individual functions to open and close the collet. Step 6:Measuring tool pull-in force

Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:If the tool pull-in force has not reached the minimum value, remove the collet and clean or replace. For procedure, see: "Repairing the collet" CloseStep 1:Step 2:Step 3:Repairing the ColletSpare part Collet See wearing and spare part list (VS) Assembly aid number 786.15090.007.0 by Messrs. Berg (supplied with the collet) Depth gauge Torque wrench for 50 Nm For manufacture's documentation on the collet, see Subsupplier's Information (ZI) from "Berg". Step 1:Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Install collet according to the installation instructions of Messrs. Berg and set to adjustment setting. Step 8:Step 9:If the tool pull-in force has not reach the minimum value despite the collet having been cleaned, the collet may be defective even if there is no visible external wear. Replace collet. Step 10:Step 11:If the tool pull-in force has not reached the minimum value despite the collet having been replaced, the tool clamping system is probably defective. Call customer service. Do not operate machine with damaged tool clamping system! Step 12:Step 13:Step 14: |