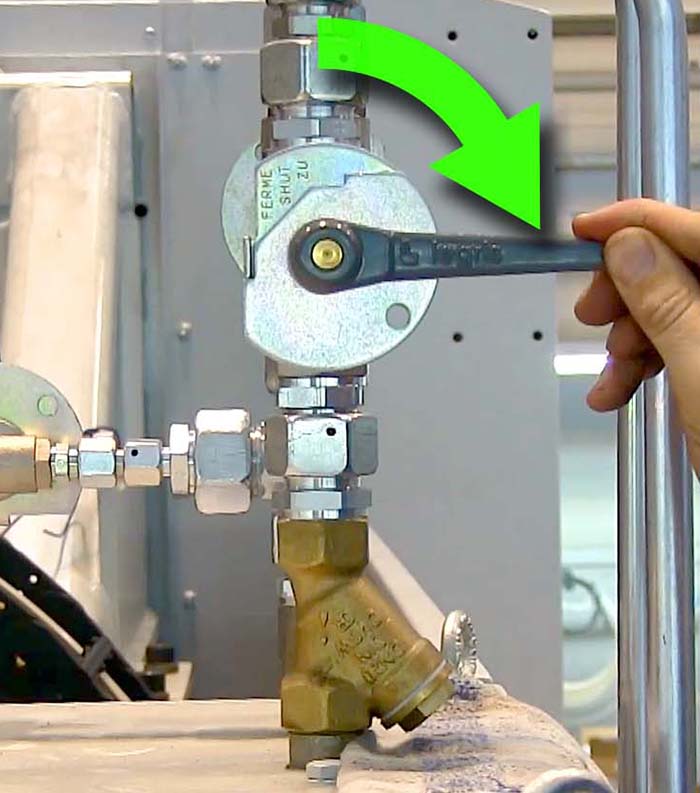

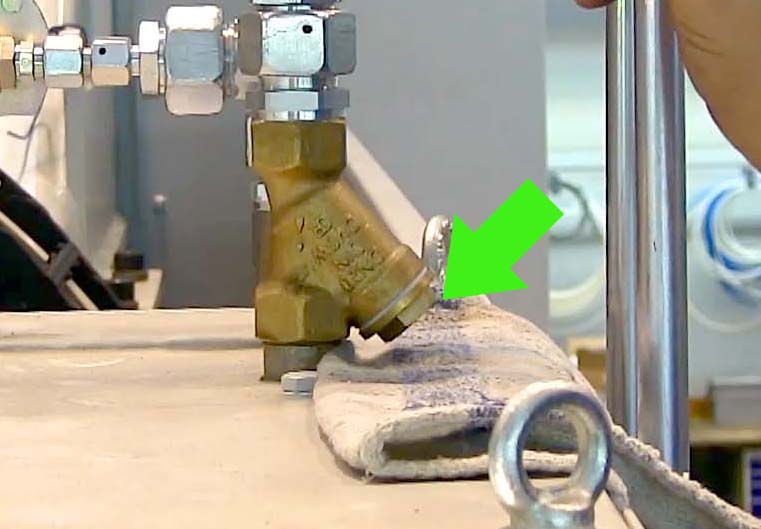

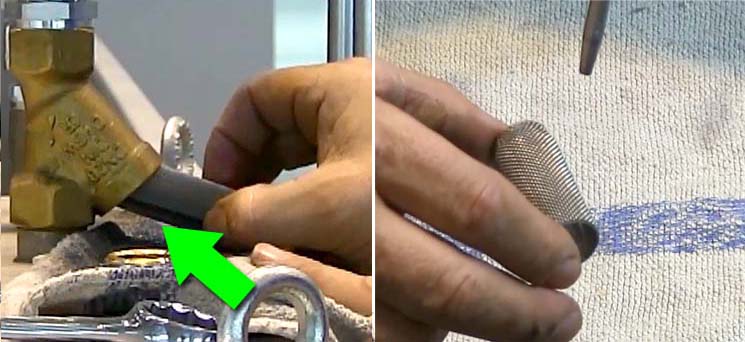

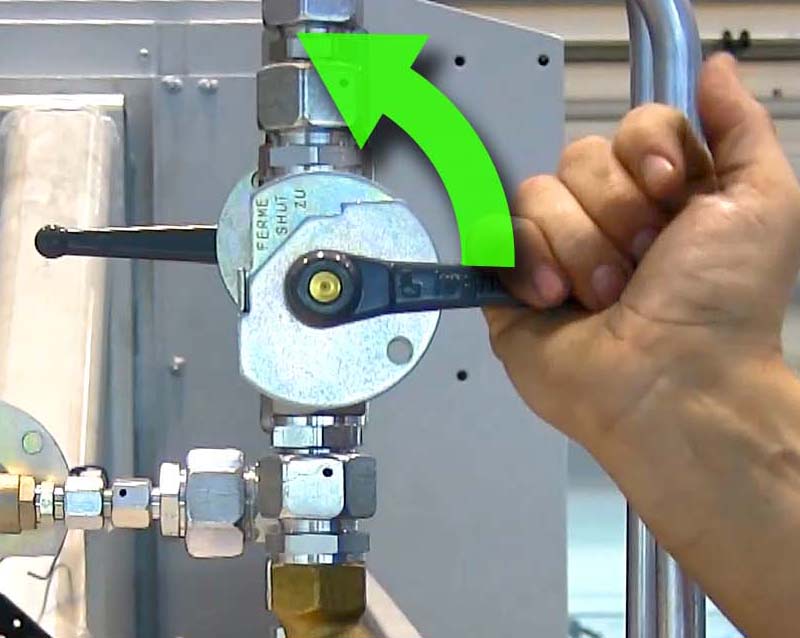

Clean Splash Guard in the Cooling Water Supply LineInterval 1000 Hours Operating time Reduce this interval in case of increased contamination level of the customer-provided cooling water. Component Cooling unit Ladder For manufacturer's documentation on the cooling unit, see Subsuppliers' Information (ZI) from "BKW". For structure of the cooling unit, see the media diagram (MP). Step 1:Step 2:Machine switched off at main switch and secured against being switched on again. This switches off the cooling unit. Step 3:Step 4:Step 5:Step 6:Step 7:Step 8:Step 9:Step 10:Before closing the maintenance safety door, ensure that nobody is behind the guard panels. Close maintenance area safety door. Step 11:Step 12: |