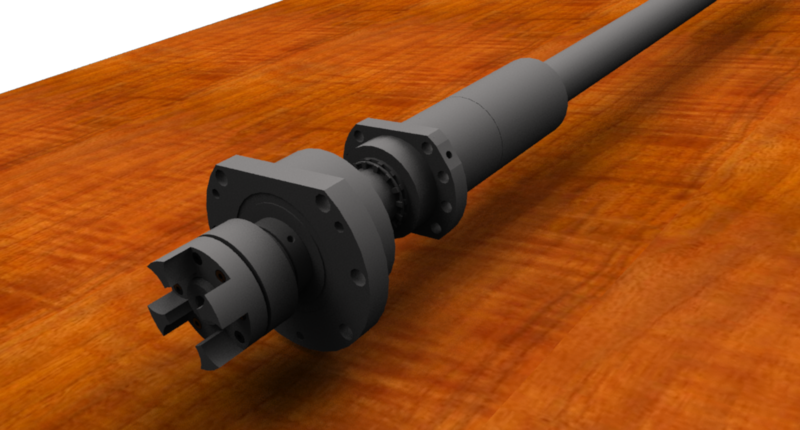

X-Axis Ballscrew Replacement

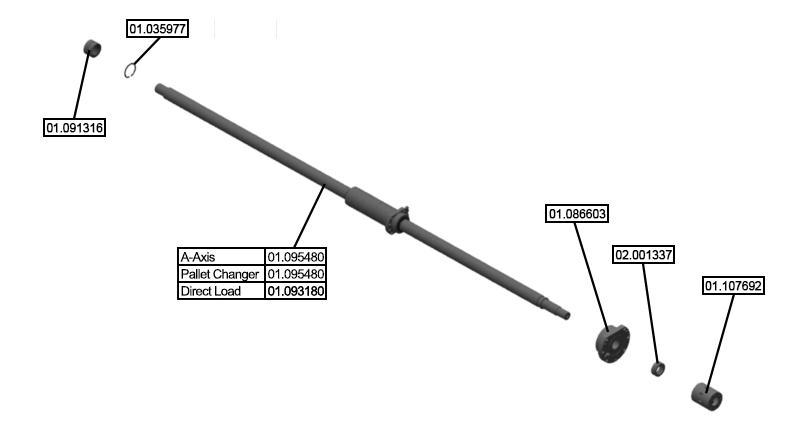

Parts List

Reference Files

Tools Required

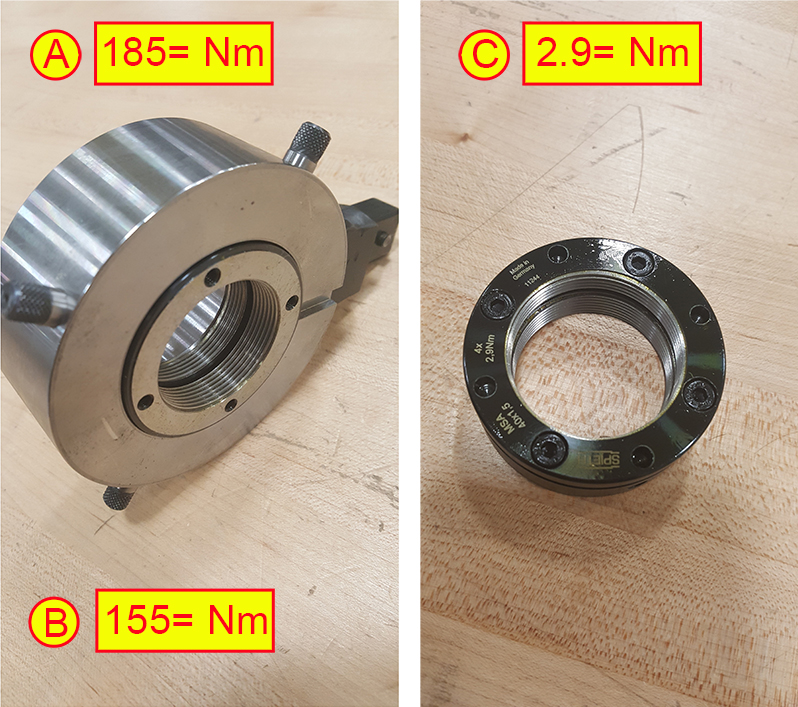

Torque Chart

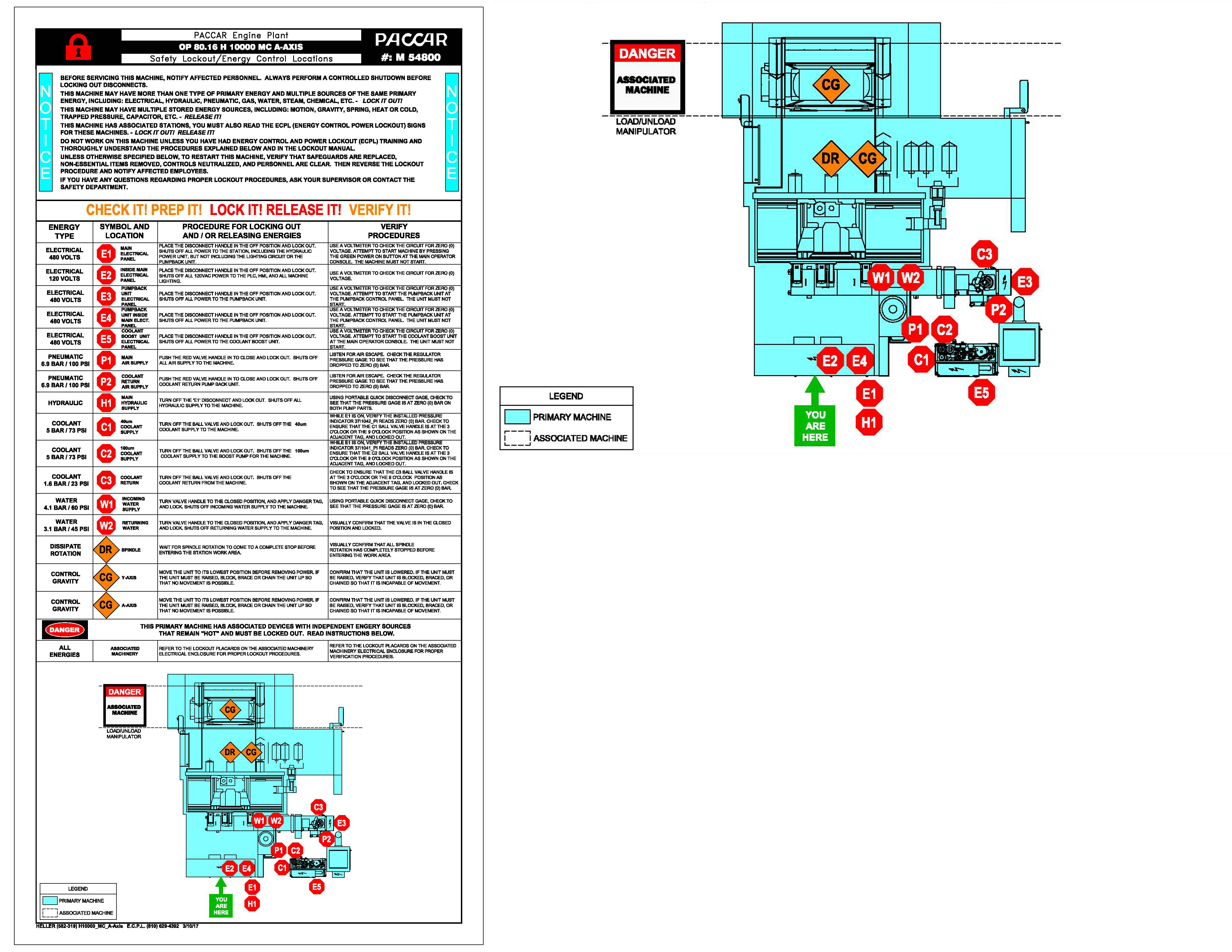

Step 1: ECPLStep 2: Refer to X-Axis Motor Replacement

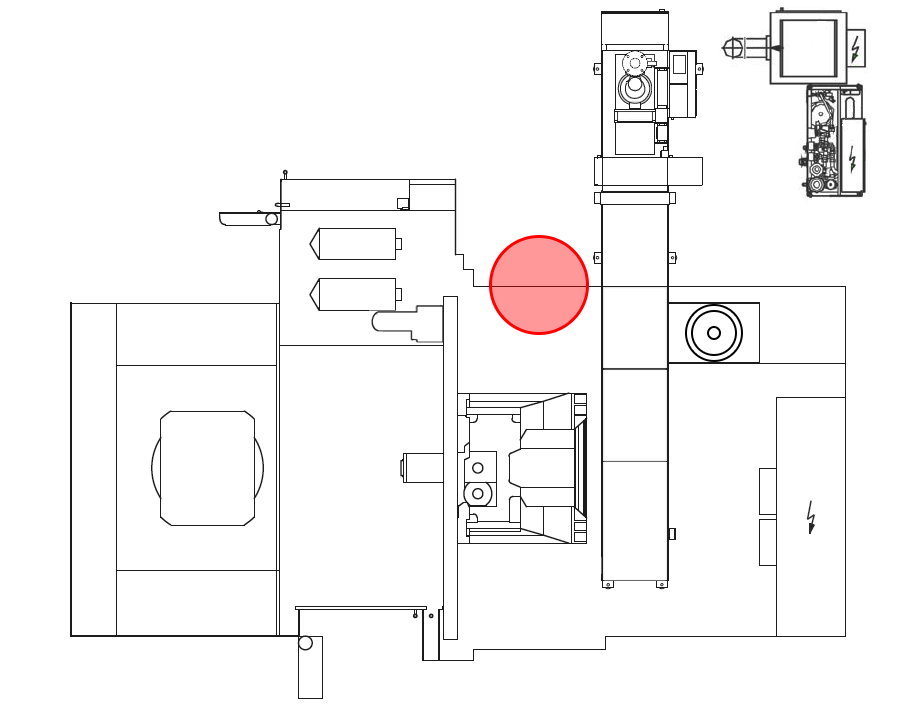

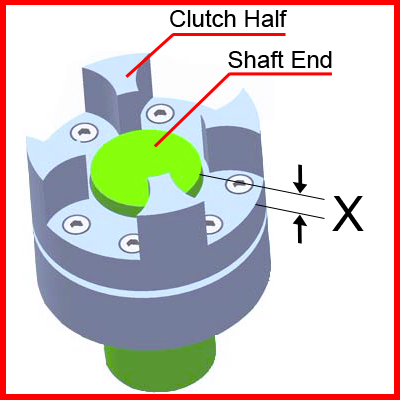

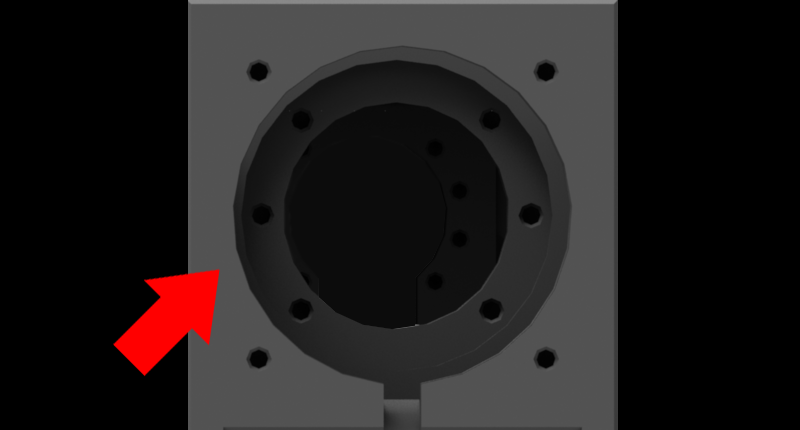

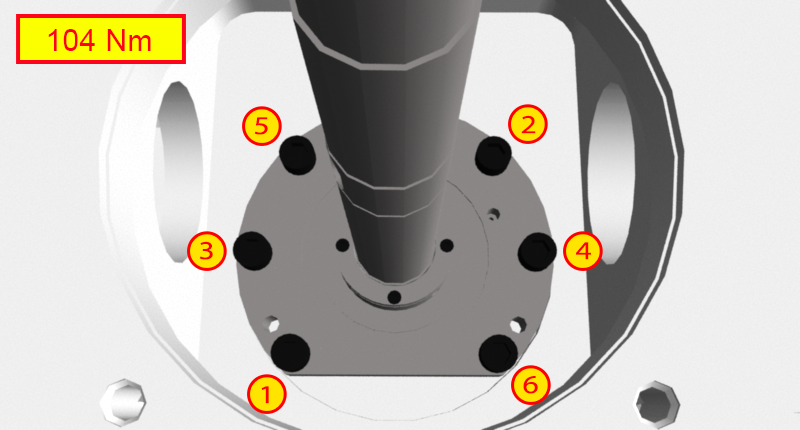

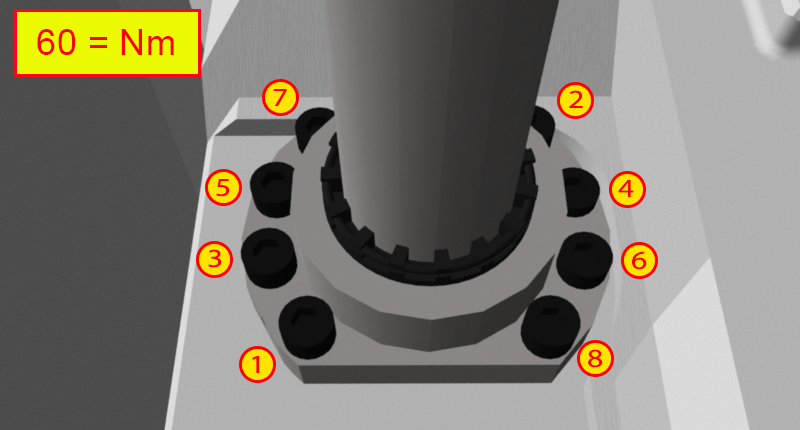

Refer to steps 2-4 of the X-Axis Motor Replacement procedure for instructions on removing the motor. Click the back button in your browser to return to this procedure. Step 3: Remove Lube Line from BearingStep 4:Remove Fasteners from BearingStep 5:Open Maintenance DoorStep 6: Remove Lube Line from BallnutStep 7: Remove Fasteners from BallnutStep 8: Insert Jack ScrewsStep 9: Remove BallscrewStep 10: Move ColumnStep 11: Remove / Install New Needle BearingStep 12: Measure CouplingStep 13:Lubricate BearingStep 14: Install BearingStep 15: Install Locknut / CouplingStep 16: Install Inner RaceStep 17: Install InsertStep 18: Move ColumnStep 19: Clean Bearing Mounting SurfaceStep 20: Clean Ballnut Mounting SurfaceStep 21: Install BallscrewStep 22: Install Fasteners into BearingStep 23: Install Lube Line into BearingStep 24: Install Fasteners into BallnutStep 25: Install Lube Line into BallnutStep 26: Refer to X-Axis Motor Replacement

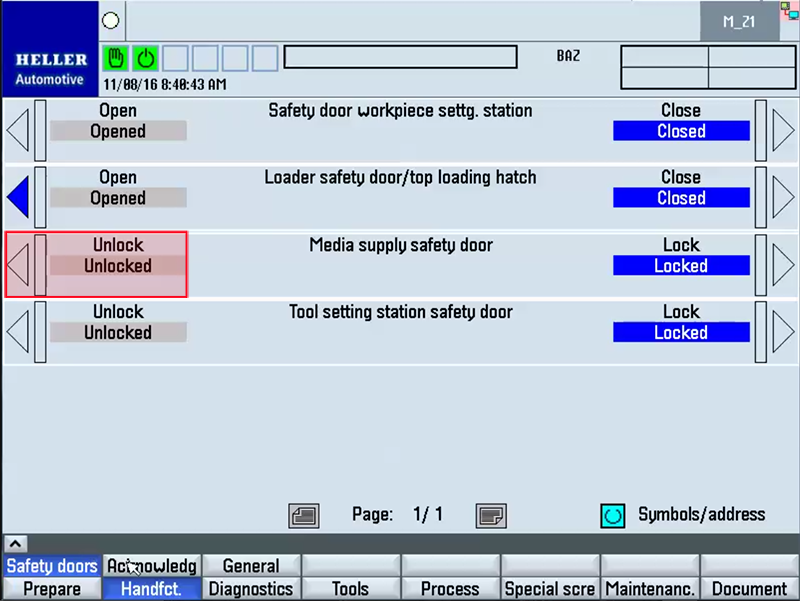

Refer to steps 11-14 of the X-Axis Motor Replacement procedure for instructions on reinstalling the motor. Click the back button in your browser to return to this procedure. Step 27: Close Maintenance DoorStep 28: ECPLStep 29: Activate Lubrication and Run-inActivate the Lubrication Cycle several times via the HMI - Prepare - Pwr-up Cond. HMI screen. After the lubrication cycles have been completed, it is now necessary to run-in the ballscrew. This can be accomplished by moving the axis back and forth along the entire length of travel at half rapid speed for 30 minutes. Then allow the ballscrew to cool for 45 minutes. Once completed, the ballscrew can now be fully loaded. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||