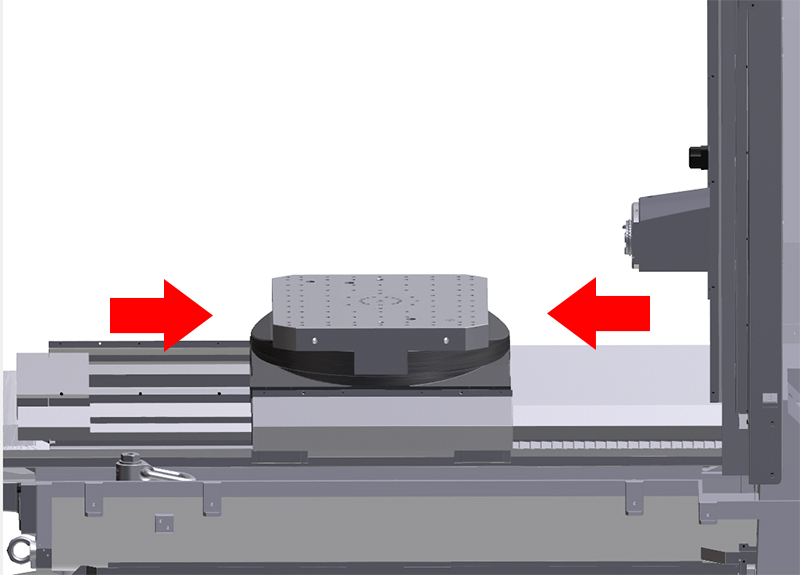

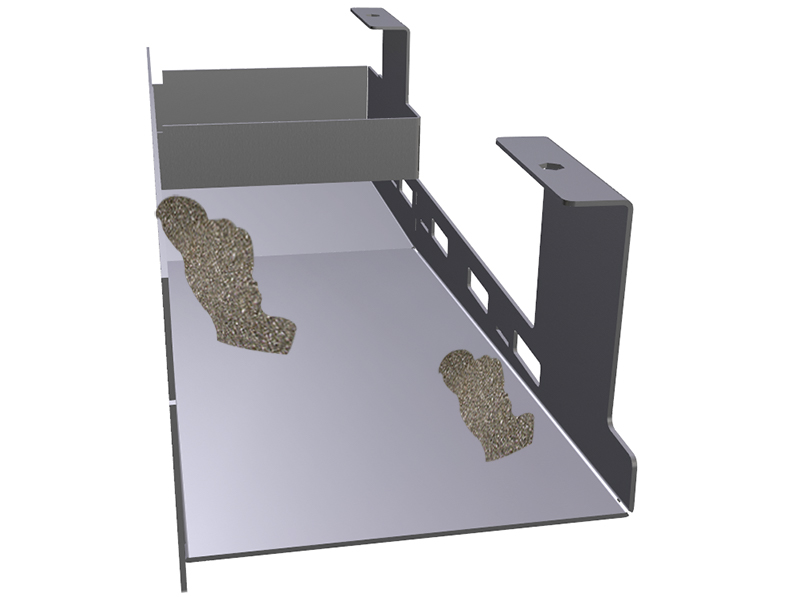

Cleaning Drip PanInterval 1 Year(s) Real time Reduce this interval depending on the contamination of the machine. Component Drip pan below the tool magazine This work should be carried out as part of the basic machine cleaning operation. For basic cleaning of the machine, please refer to: "Cleaning the machine" Vessel with soapy water for cleaning the filter container Procedure Please observe "Special safety measures" when entering or leaving the machine. Exercise extreme caution when working in the maintenance area with unsecured machining unit! Avoid working below the machining unit! Step 1:X and Y-axis positioned so that the drip pan is safely accessible:

Step 2:Step 3:Step 4:Step 5:Step 6:Step 7:Before closing the maintenance openings, ensure that nobody is behind the guard panels. Close maintenance openings B, C and D. |