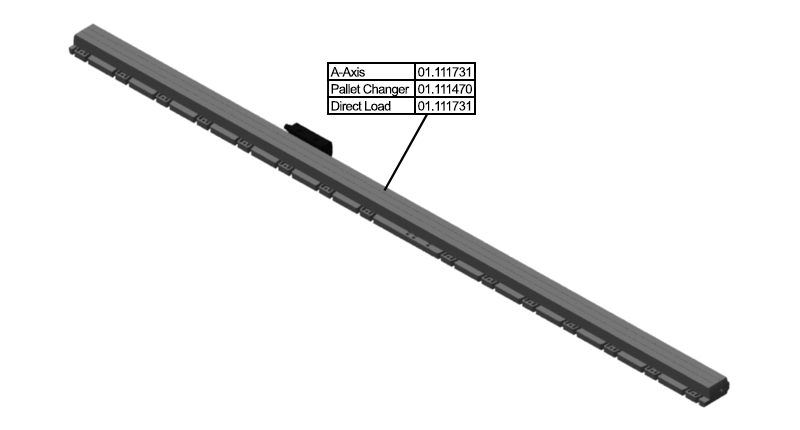

X-Axis Length Measuring System

Parts List

Reference Files

Tools Required

Torque Chart

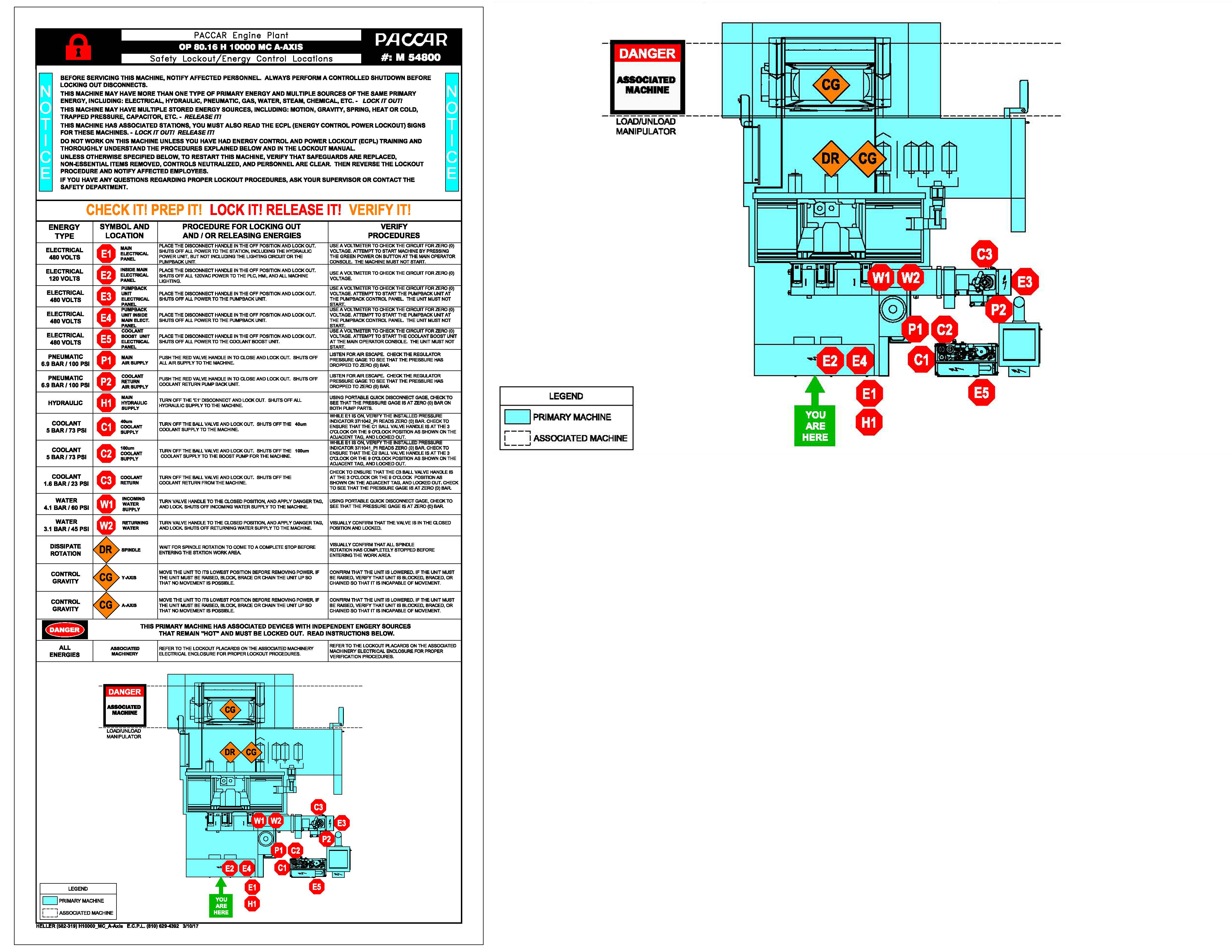

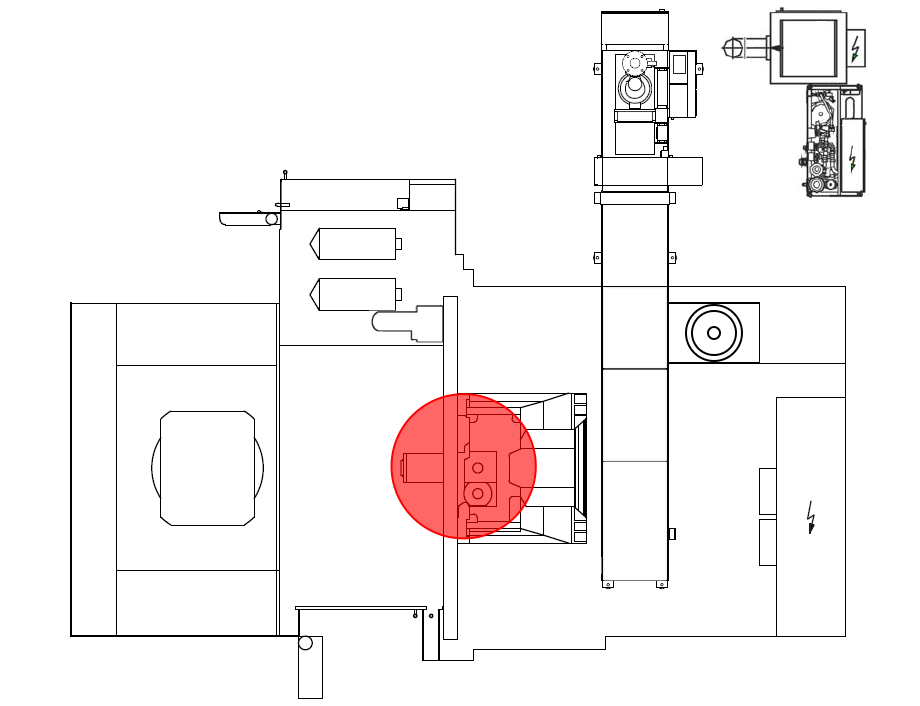

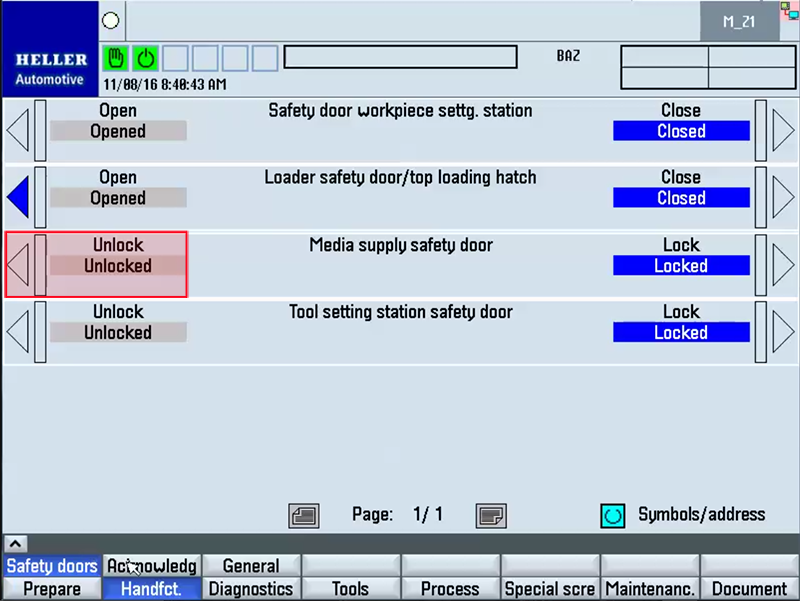

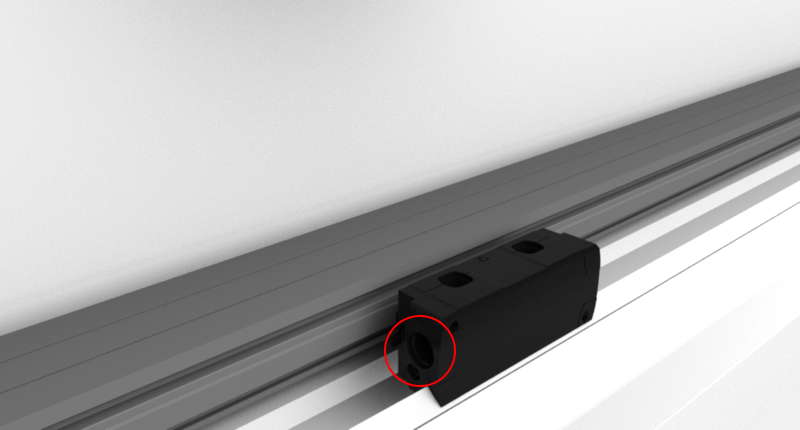

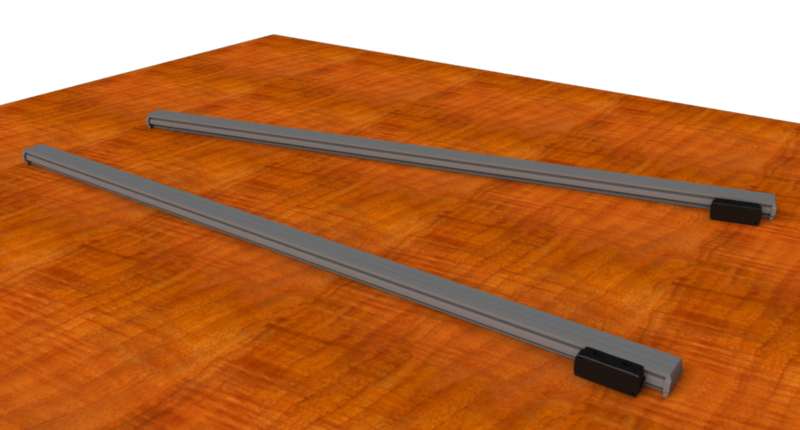

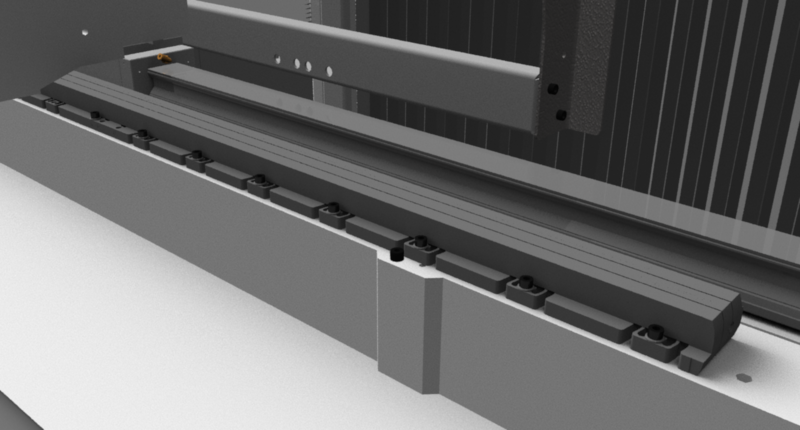

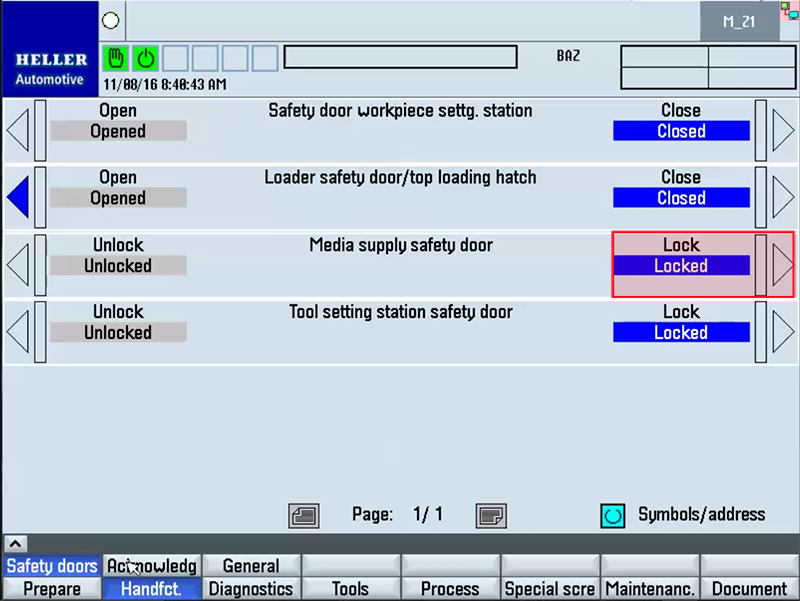

Step 1: ECPLStep 2: Remove Maintenance OpeningsStep 3: Jog X and Y AxisStep 4: Open Rear Maintenance Safety DoorStep 5: Block Machining UnitStep 6: Remove Air PurgeStep 7: Remove Accessible ScrewsStep 8: Jog to CenterStep 9: Open Work Area Safety DoorStep 10: Remove Concertina CoverStep 11: Remove Electrical ConnectionStep 12: Remove Read Head ScrewsStep 13: Jog X AxisStep 14: Open Operator Side Maintenance OpeningStep 15: Remove the Currently Accessible ScrewsStep 16: Remove the Scale from the MachineStep 17: Replace with New Scale (will have shipping brackets)Step 18: Make Sure Mounting Area is CleanStep 19: Insert Scale into Machine (align to pins)Step 20: Insert Accessible screws (do NOT torque)Step 21: Jog To CenterStep 22: Install Read Head Screws and Remove Shipping BracketsStep 23: Install Electric ConnectionStep 24: Close and Secure Concertina CoverStep 25: Jog to Opposite SideStep 26: Insert Now Accessible Screws and TorqueStep 27: Connect Air PurgeStep 28: Jog to Opposite SideStep 29: Torque remaining ScrewsStep 30: Close Operator Side Maintenance OpeningStep 31: Close Work Area Safety DoorStep 32: Close Maintenance OpeningsStep 33: Close Rear Maintenance DoorStep 34: ECPL |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||