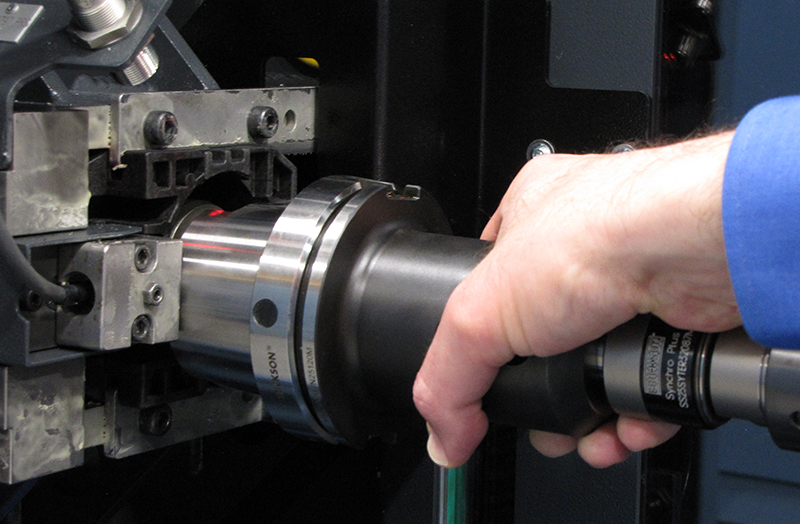

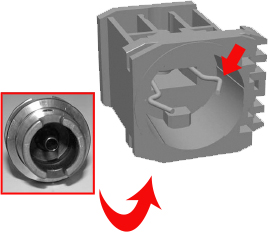

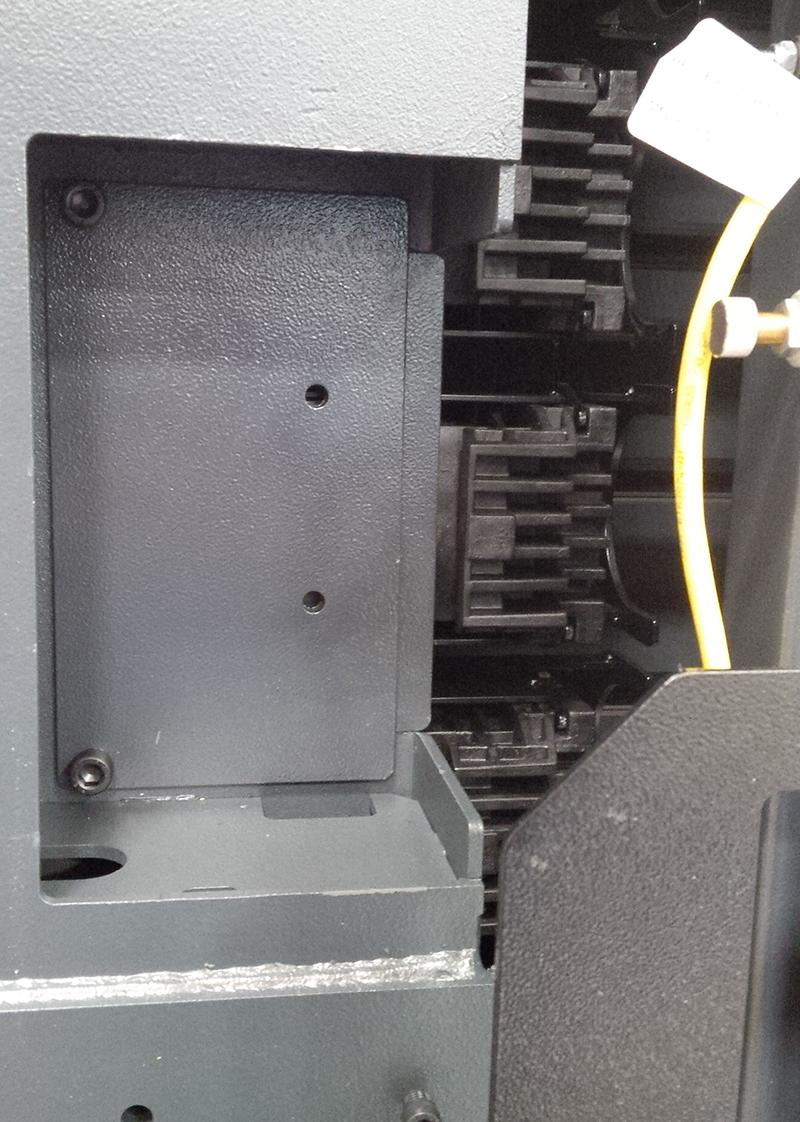

Cleaning and Checking Tool Holders, Tool Cartridges and ToolsInterval 1000 Hours Operating time Component All tool holders, tool cartridges and tools InspectionStep 1:Step 2:Step 3:Step 4:Step 5:Clean tool and check for wearing:

Step 6:Step 7:Remove tool cartridge if damaged. For procedure, see: "Replacing tool cartridge or tool holder" Step 8:Clean and check tool holders:

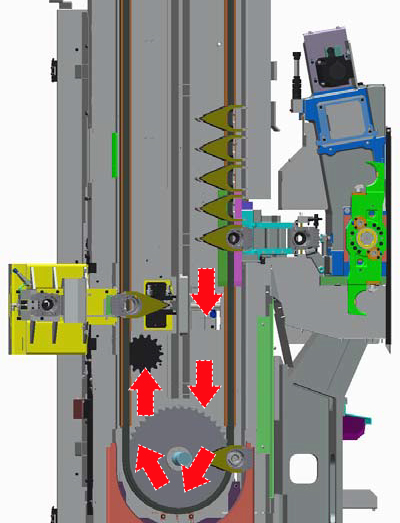

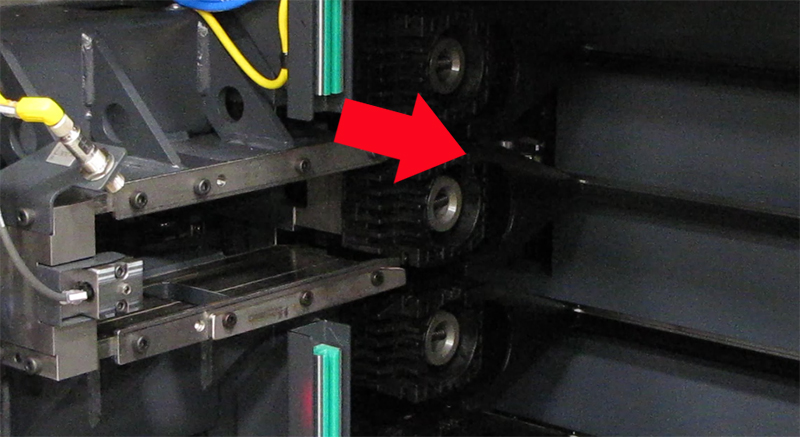

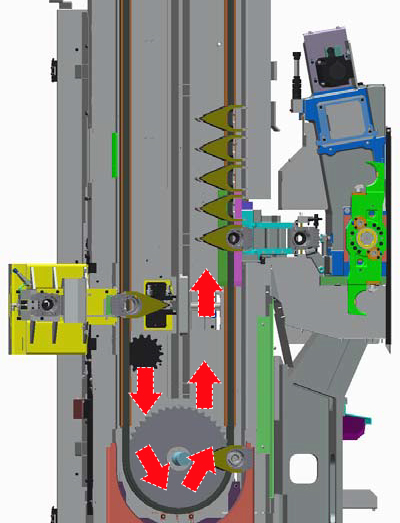

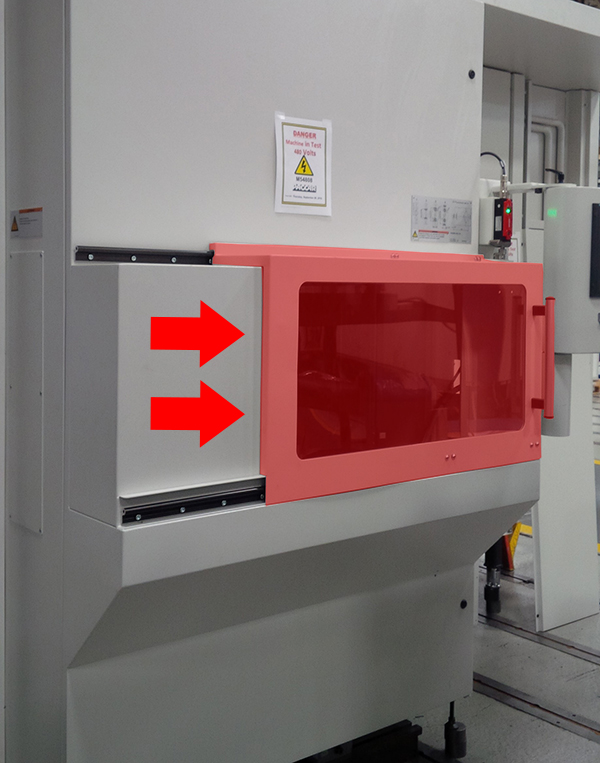

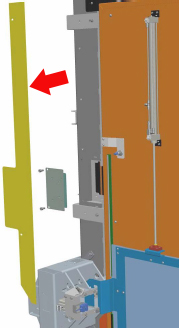

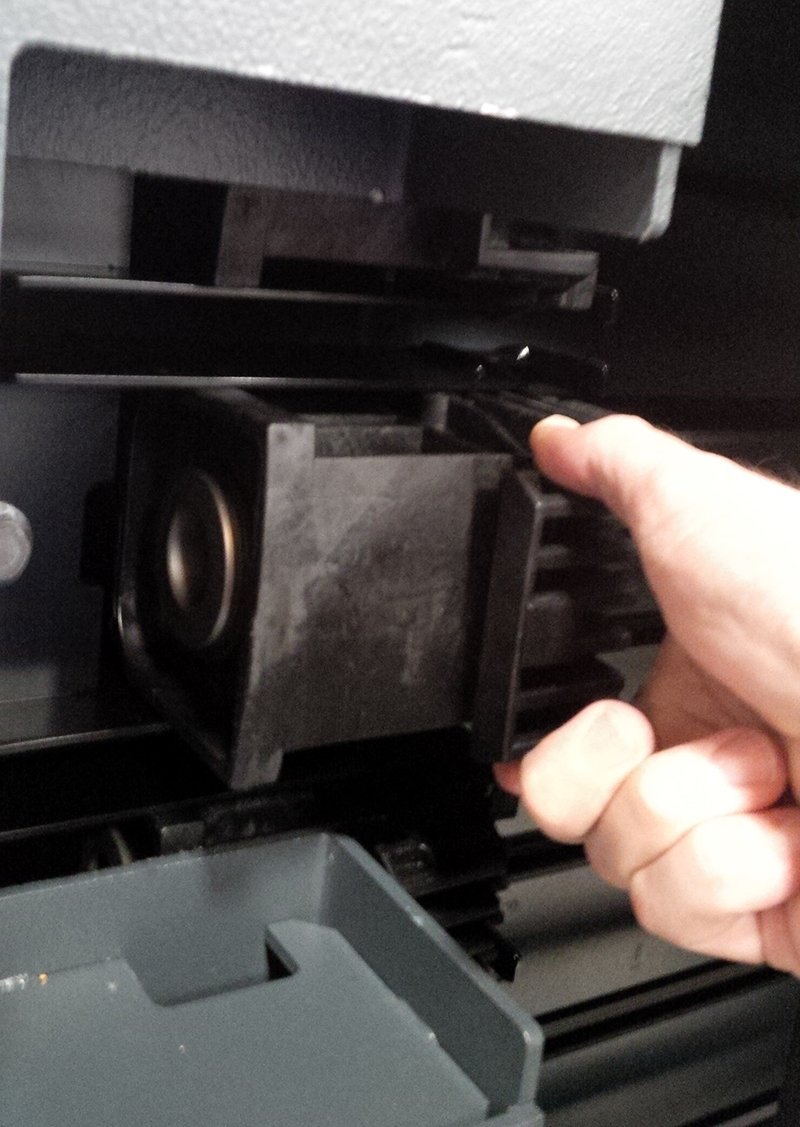

Step 9:Remove tool holder if damaged. For procedure, see: "Replacing tool cartridge or tool holder" Step 10:Step 11:Step 12:Check all other magazine places in the same way. Step 13:Replacing Tool cartridge or tool holderSpare part Tool cartridge Tool holder See wearing and spare parts list (VS) Ladder Observe Section 4.2 "Special safety measures" before opening the tool magazine maintenance door. Step 1:Step 2:Step 3:Move magazine place with defective tool cartridge or defective tool holder to the cartridge unloading position. The cartridge unloading position is 5 locations above the conveying station to the tool setting station. Step 4:Step 5:Step 6:Open maintenance door of the tool magazine. For more information on how to open maintenance door see: "Opening the chain magazine maintenance door" Step 7:Step 8:Step 9:Step 10:Step 11:If the tool holder is defective:

Step 12:Step 13:Step 14:Step 15:Before closing the maintenance door, ensure that nobody is behind the guard panels. Close the maintenance door of the tool magazine. Step 16: |