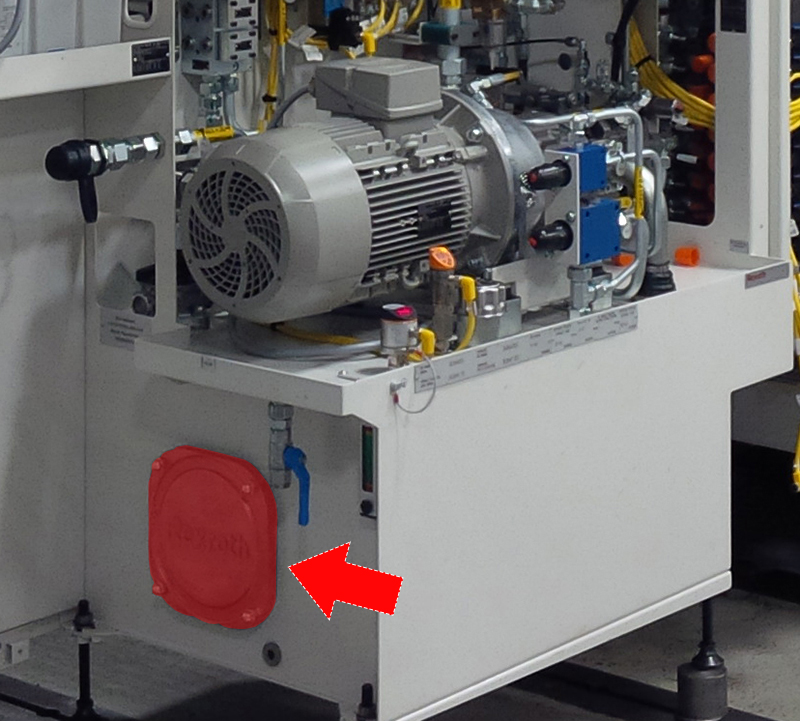

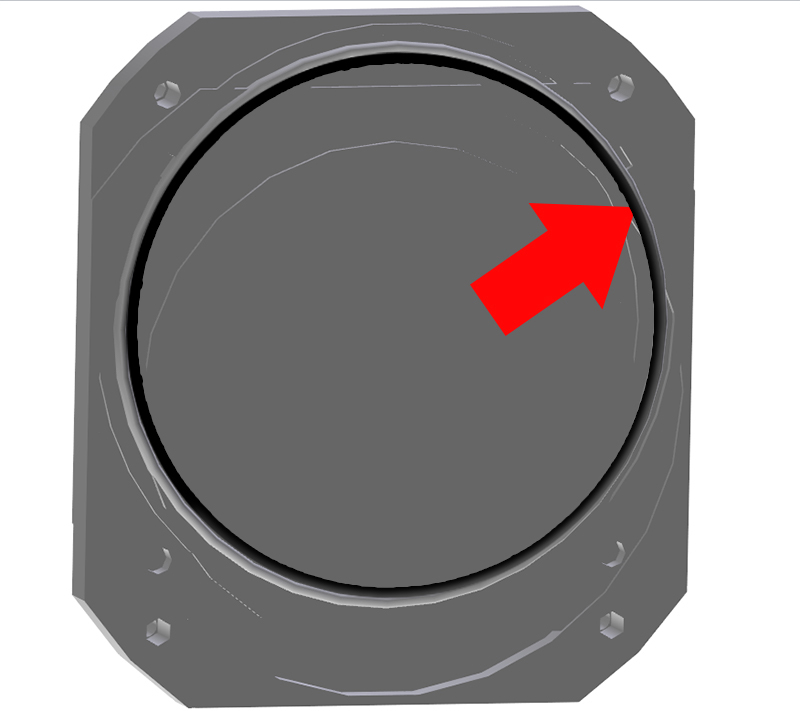

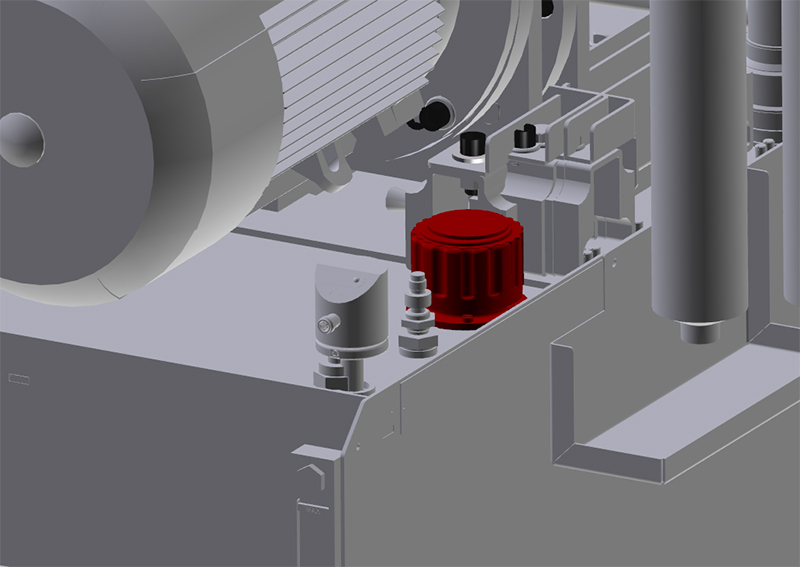

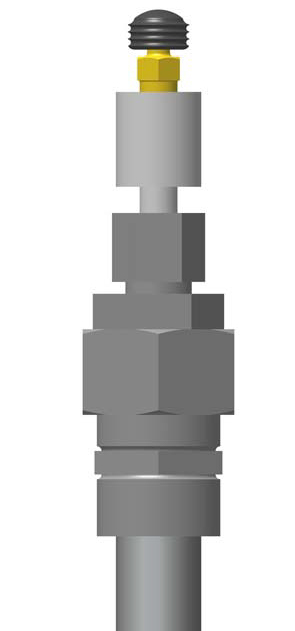

Oil Change in Hydraulic ReservoirInterval 1 Year(s) Real time Component Hydraulic unit Consumable Hydraulic oil HLP 46 to DIN 51524, Part 2 (ISO-L-HM 46 to ISO 6743, Part 4) Purity class ISO 4406-18/16/13 For tank capacity, see hydraulic circuit diagram (HP) Disimilar lubricants can contain various additives that might not be compatible. To rule out incompatibility between the lubricants, disimilar lubricants must not be mixed. If you have any questions, please contact your lubricant supplier. Used oil must be regarded as hazardous waste and be disposed of according to the locally applicable regulations. Spare part Cleaning cover seal 01.102524 Filling strainer See Hydraulic Diagram (HP). Contaminated filter elements must be regarded as hazardous waste and disposed of according to the locally applicable regulations. Oil extractor Hose with a diameter of 8 x 1.25 mm to ventilate the hydraulic unit Torque wrench for 10 Nm For structure of the hydraulic system, see the Hydraulic Diagram (HP). Emptying Hydraulic ReservoirProcedure Machine switched off at main switch and secured against being switched on again. Screw off filling strainer cap. Remove the fixing screws on the filling filter filling sieve. Remove filling sieve. Dispose of the used filling strainer. Exhaust oil through filling opening in filling filter. Cleaning the Hydraulic ReservoirStep 1:Step 2:Step 3:Step 4:Filling OilProcedure Fill with oil through filling opening in filler filter up to the max. mark on the oil level indicator. Screw down the filter cap of the filling strainer. Checking Filing level in axial piston pumpDepending on the piston position, the axial piston pump may run out via the suction line after you have emptied the hydraulic reservoir. Check and refill as described in the following in order to avoid that the pump runs dry on start-up and seizes. Note that, depending on the design of your machine, the filler plug may be in a different position. Procedure Check and top up filling level in axial piston pump:

Vent hydraulic unitProcedure Vent hydraulic unit:

Run machine for a few minutes. Check screw plug and cleaning cover for leakages. Check oil level at the oil level indicator. Fill with oil up to maximum mark. |