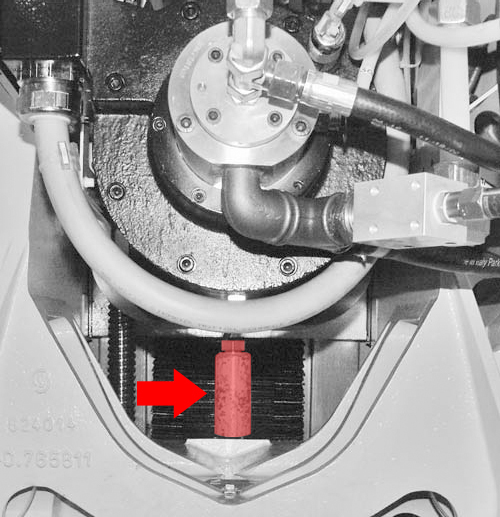

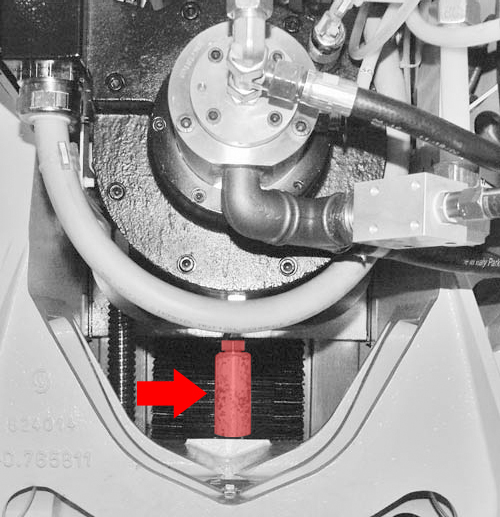

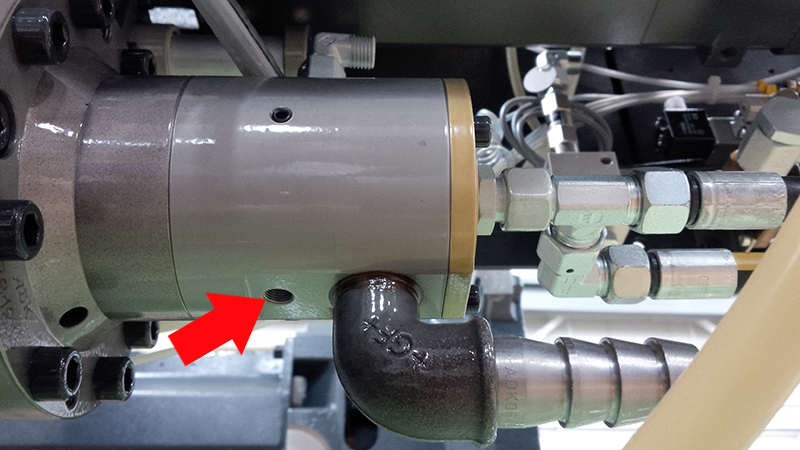

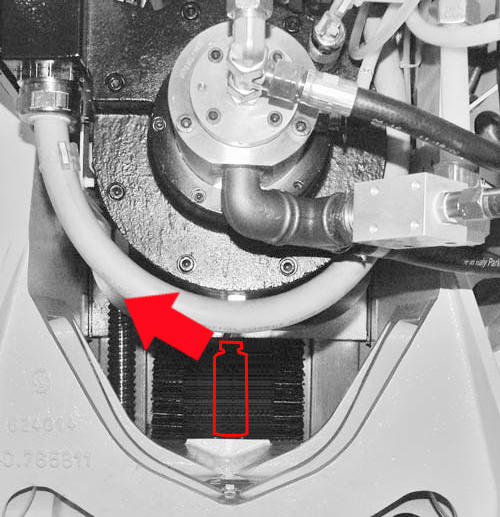

Checking Leakage Discharge of the Rotary DistributorInterval 500 Hours Operating time Component Rotary distributor When the coolant supply is switched on, cooling lubricant continually flows through the connected hose. Only single drips should escape from the bore. Please observe chapter 4.2 "Special safety measures" when entering or leaving the machine. Step 1Step 2Step 3Step 4Step 5Step 6Increased leakage occurs on the bore of the rotary distributor. This indicates missing seal air. Check air supply to the rotary feed. For procedure, see: "Inspection of fluid equipment" Step 7In case of continuously increased leakage on the bore of the rotary distributor, seals inside the rotary distributor are defective. Have the rotary distributor replaced by the customer service. Do not operate the machine with a defective rotary distributor. Step 8Step 9 |