Functions in Auto ModeMove machine to home positionStep 1:The home position is the defined starting point for many NC

programs. In the home position, the Z-slide is retracted and in the "Start position". Machining of the workpiece can be started from here.

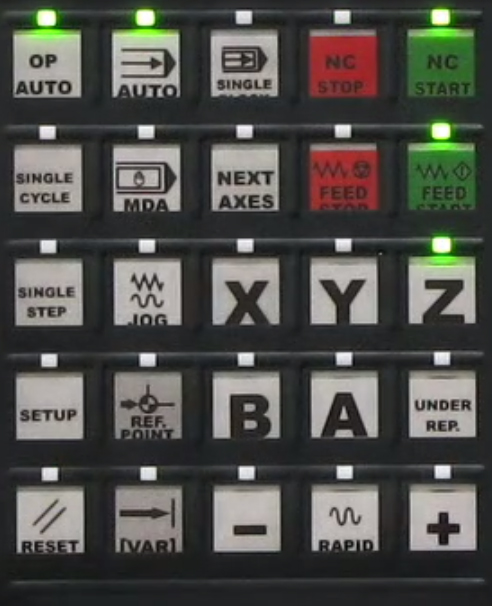

Press OP Auto and Auto keys. Step 2:Press the Master Return key.

The lamp comes on when the home position is reached. Starting productionStep 1:Preconditions:

Press the Interlinked Operation Mode (OP Auto) key.

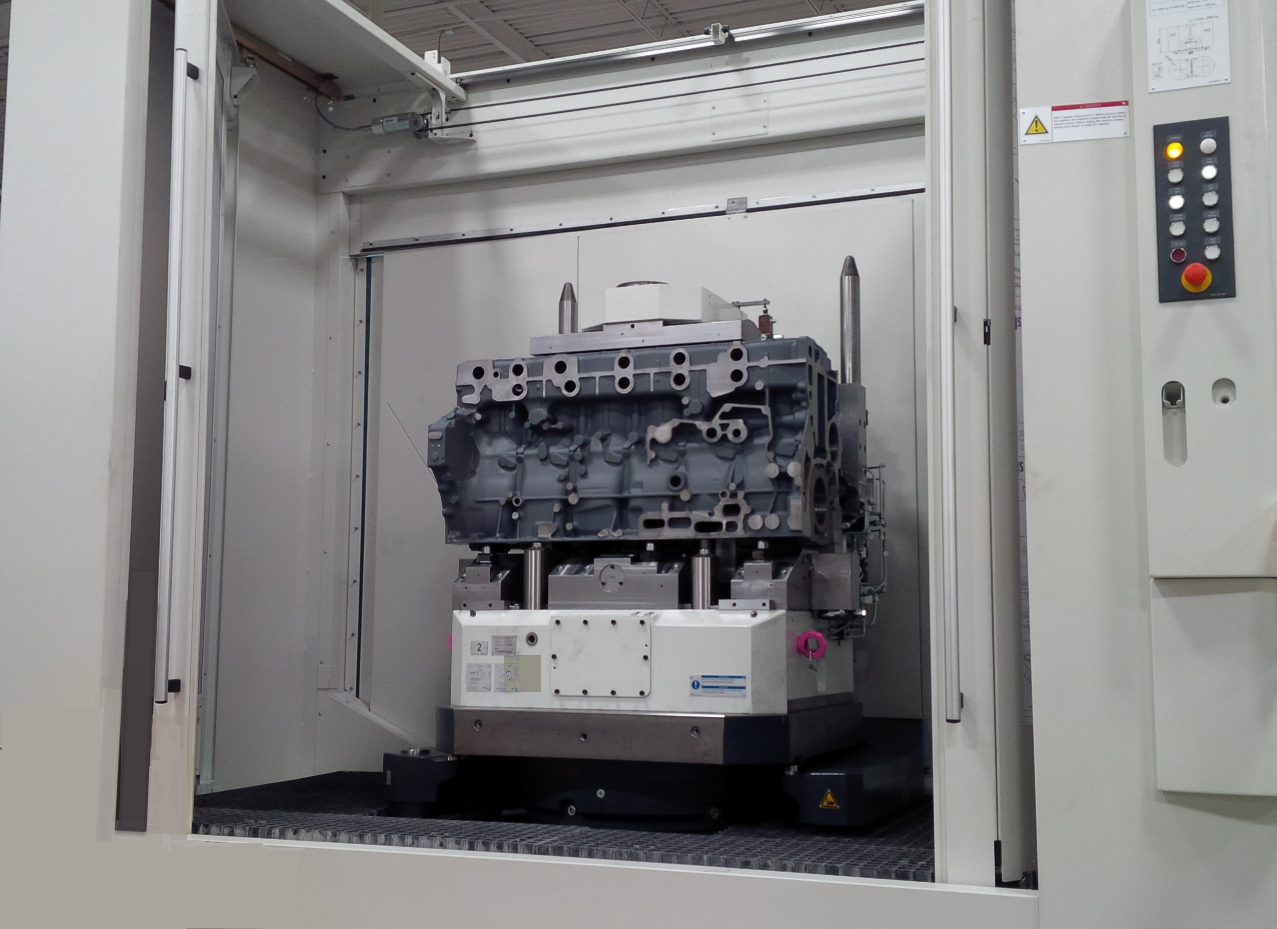

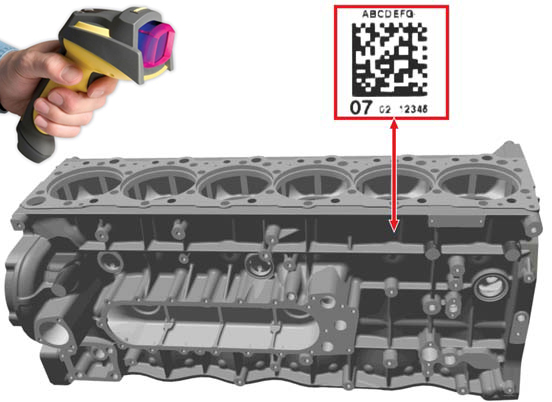

Step 2:Press the Start/Step key. Step 3:Preconditions: Step 4:Step 5:Place a raw part on pallet 1 at the setting station. Step 6:Step 7:Opening the "General" HMI screenStep 1:Preconditions:

Press the Setup key.

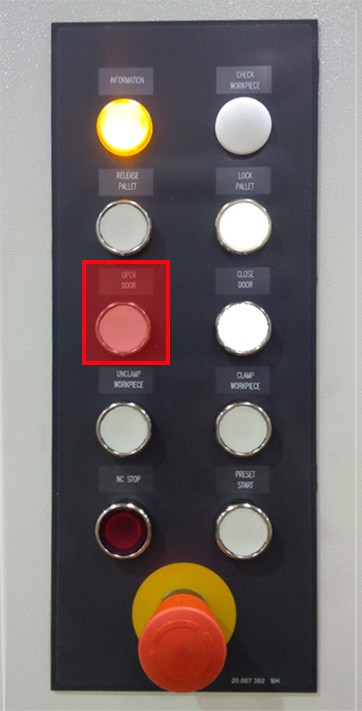

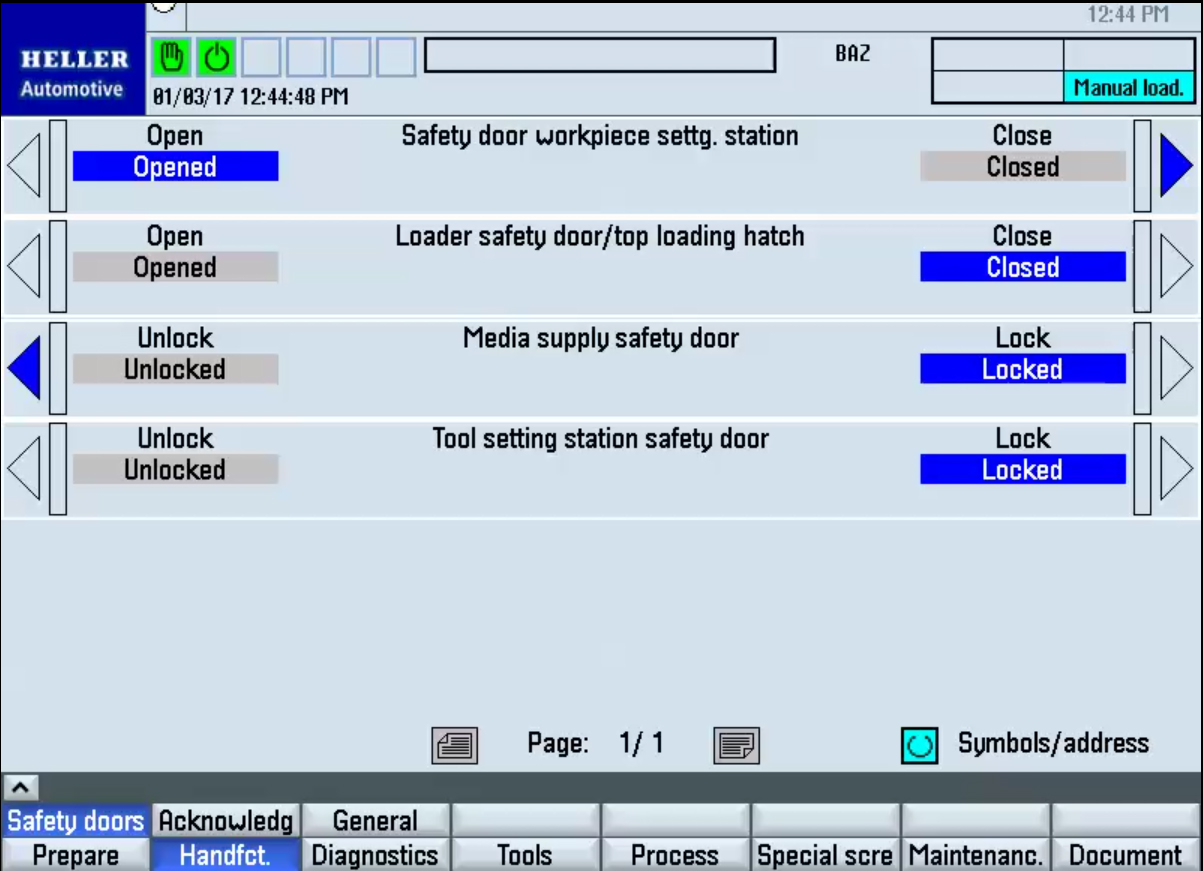

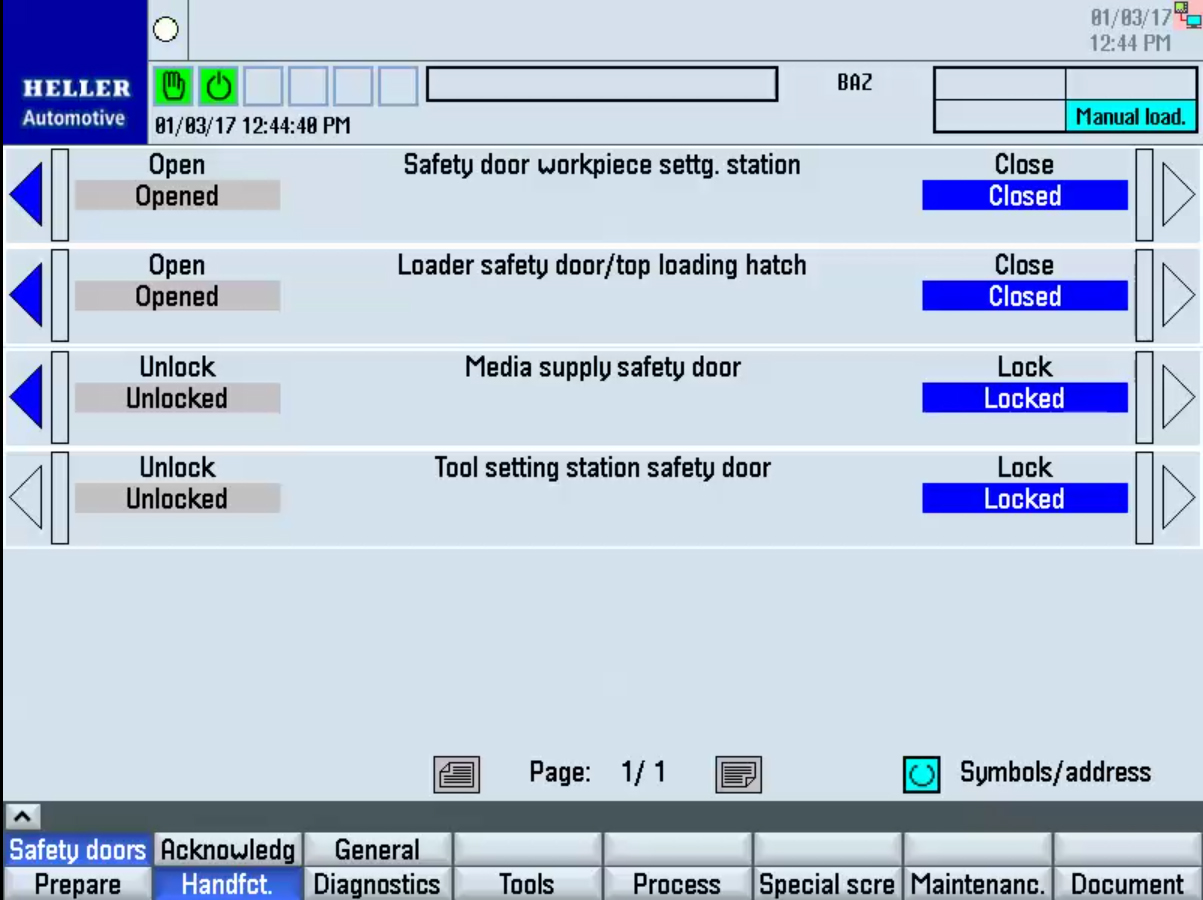

The machine is removed from the system linkage. Setup mode is activated. With Data menu key call up the basic menu on the main operator panel. Press the "HMI" softkey. Step 2:With Data menu key call up the basic menu on the main operator panel. Press the "HMI" softkey. Step 3:Workpiece ChangeStep 1:Press upper horizontal softkey "WPC". Step 2:Unclamp Fixture Step 3:Step 4:If necessary, blow off chips from the fixture rest points. Step 5:Step 6:Clamp Fixture Step 7:Press the Start/Step key. Basic informationThe warmup circuit enables a program to be started automatically

every weekday (including Saturday and Sunday). This allows the

machine to be run up to operating temperature before machining the

first workpiece. Damage to the machine and workpiece can be

reduced to a minimum and a high degree of machining accuracy

achieved in the initial stages of production. Open the "Warm-up program" windowStep 1:Preconditions:

Call up the machine's basic menu using the Data menu key. Step 2:Press the "Warmup" softkey. Edit modePrecondition: Setting timeStep 1Use the Cursor keys to select the input field for the hours display of

the desired day of the week. Select warmup programThe following restrictions apply for the warm-up program: Step 1Press Tab to select the "NC program" input field for the desired day

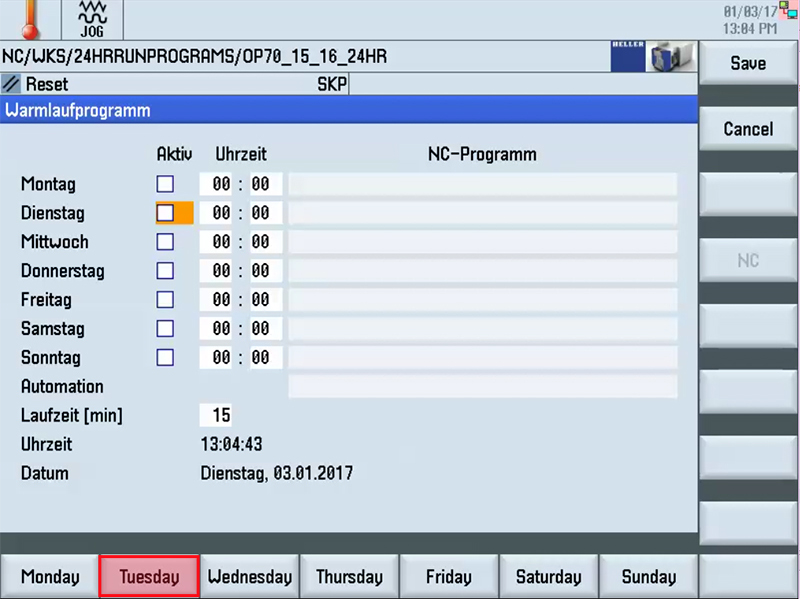

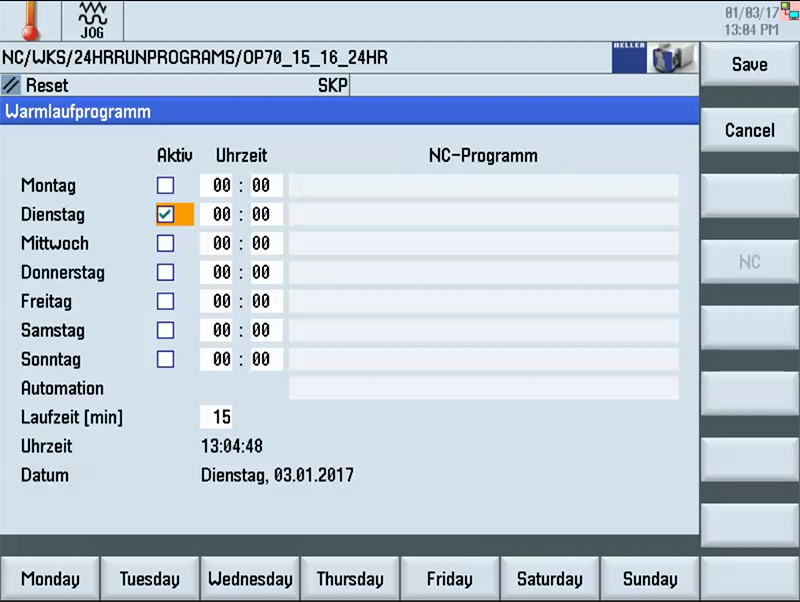

of the week. Step 2Press the "NC" softkey. Start Warmup programUse the Checkbox in the "active" column to switch the program for

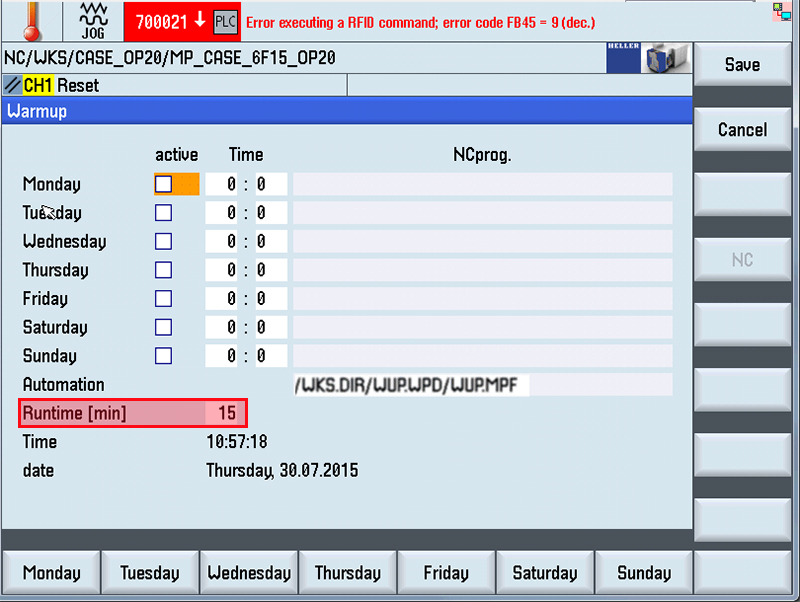

the day of the week on or off. Step 1Step 2Setting maximum runtimeStep 1The duration of the warmup sequence is entered in minutes in the

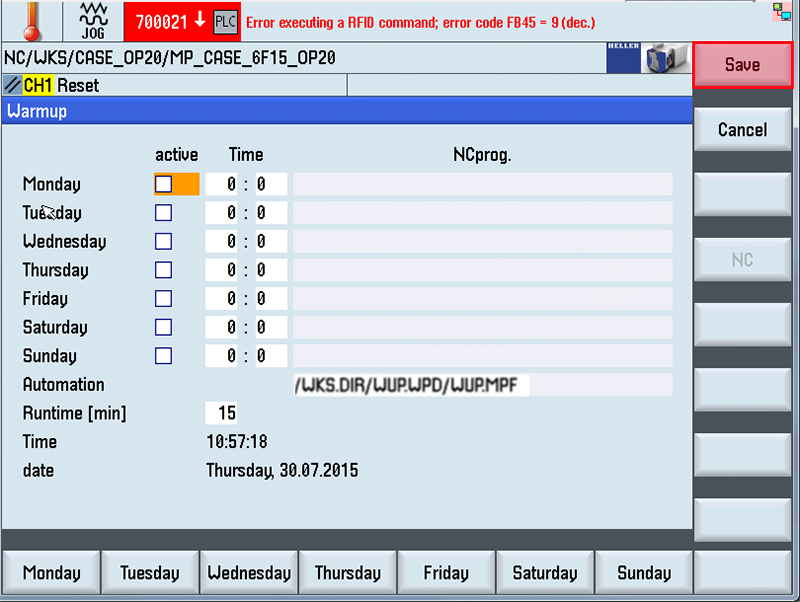

"Runtime" field; valid values: Close edit modeStep 1Important HintsPressing the Reset button during warmup interrupts the program. Information on tool spindle warmupIn order to guarantee even distribution of the lubrication oil after

down times, you must prepare the spindle by warming-up. Start warmup programStep 1Preconditions:

Press the Master Return key. Step 2Step 3To indicate that a warm-up is currently running, the message "Warmup

program active - cancel with reset or automatically once the

setpoint time has expired at end of program" is displayed.

Normal mode is possible again only when the cycle type "Preselect warm-up function" has been deselected. Stopping the warm-up program manuallyStep 1The warm-up program stops either automatically or after the

specified runtime or via manual intervention. Step 2Switch-off warm-up function in the "Cycle types" HMI screen

("Prepare" area). Step 3Also press the Master Return key. Step 4Press the Start/Step key. |

The basic menu is expanded in a horizontal direction.

The basic menu is expanded in a horizontal direction.