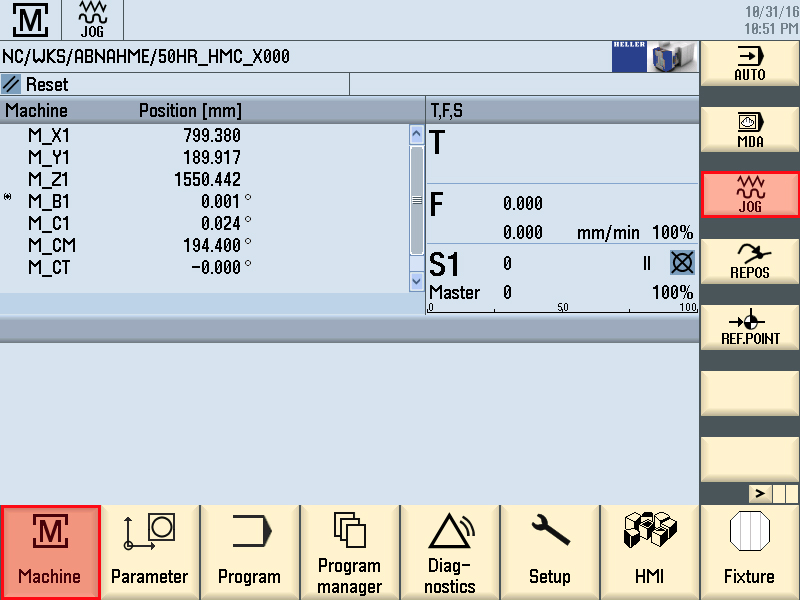

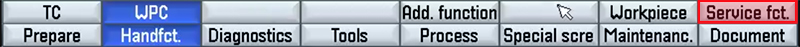

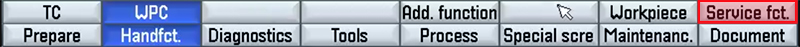

Service FunctionsCall Up Service FunctionsPreconditions:

Press lower horizontal softkey "Man.funct.".

HMI screens are available for the following machine components:

Fast Drill Breaking

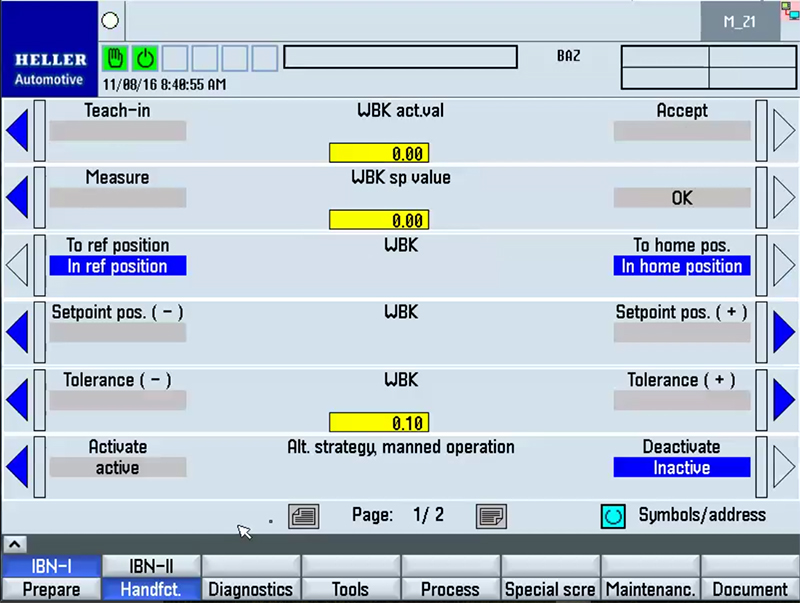

WBK act.valManually teach a tool that is located on the provisioning place.

WBK sp valuePressing the left softkey executes a measurement on the tool that is located at the provisioning place. If the difference of the measured value, compared to the reference value, is greater than the tolerance value, an error message is output. WBKFunction for moving the tactile probe to the preferred angle values.

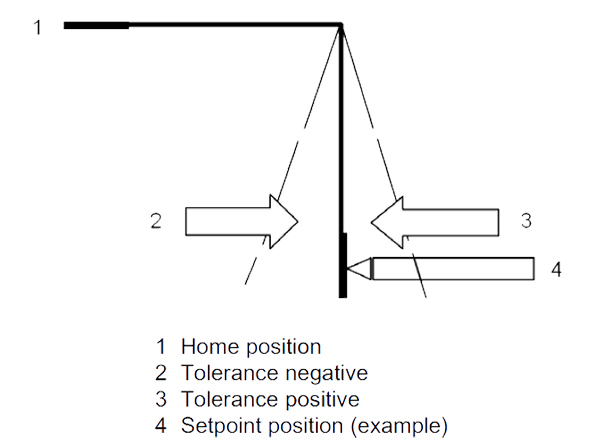

WBKFunction for entering the setpoint position for the tactile probe. The

input value appears in the yellow field.

Setpoint pos. ( - ): Alter position in small increments:

Setpoint pos. ( + ): Alter position in large increments:

Function for entering the tolerance value for the tactile probe. The tolerance value appears in the yellow field (typically 0.5 degrees).

Call Up Service FunctionsPreconditions:

Press lower horizontal softkey "Man.funct.".

HMI screens are available for the following machine components:

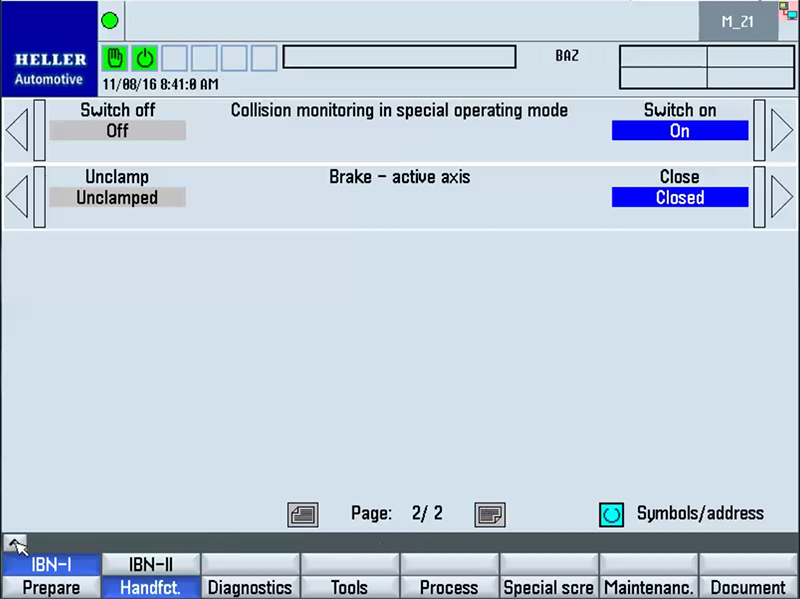

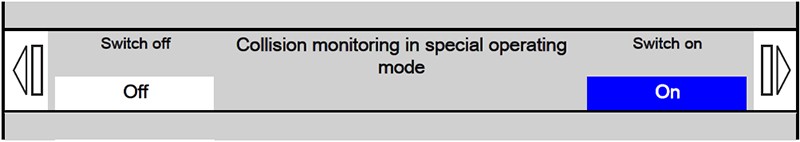

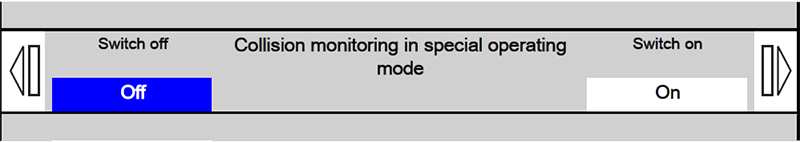

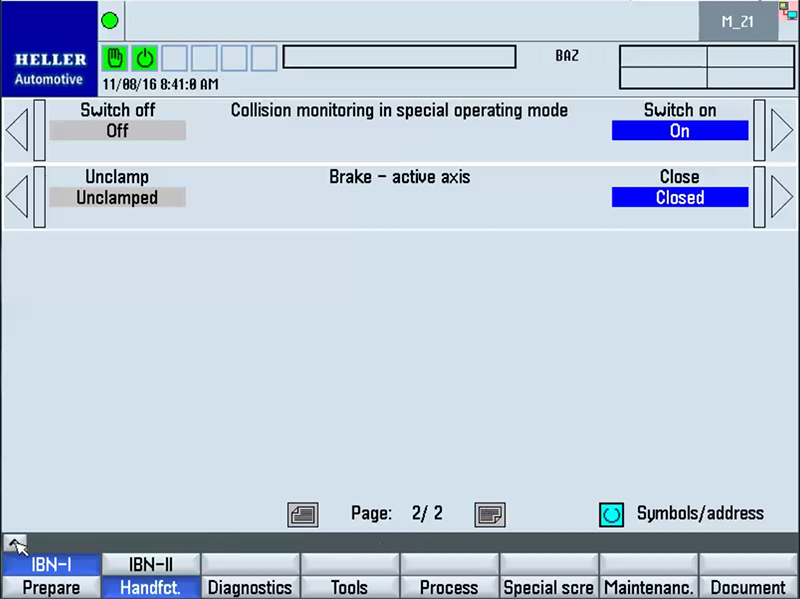

Collision monitoring in special operating mode "SETUP""Collision monitoring off"In normal operating mode "AUTOMATIC", collision monitoring is switched on and off with the Approval key key.

"Approval for traversing movement"In special operating mode "SETUP", the Approval key is use, to even

release traversing movements of individual axes. However, in this

case, the collision monitoring is switched on for safety reasons

(standard setting).

With an open safety door, the above setting can be used to move axes without collision. "SETUP" special modeCollision monitoring deactivated

In certain exceptional situations, when pallet or tool changers no longer react to individual functions, it may be necessary to turn collision monitoring off in special operating mode "SETUP".

This allows movements to be continued or a default position to be approached when the system is in an undefined condition. Call Up Service FunctionsPreconditions:

Press lower horizontal softkey "Man.funct.".

HMI screens are available for the following machine components:

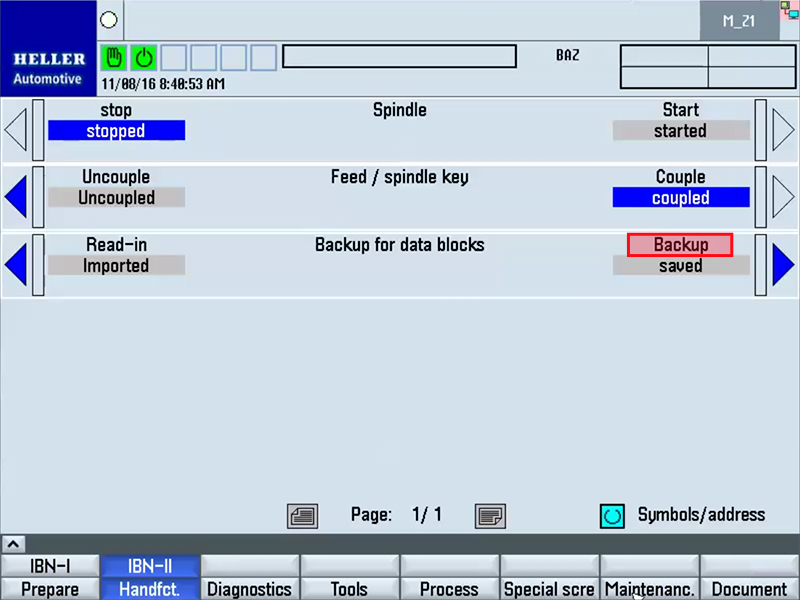

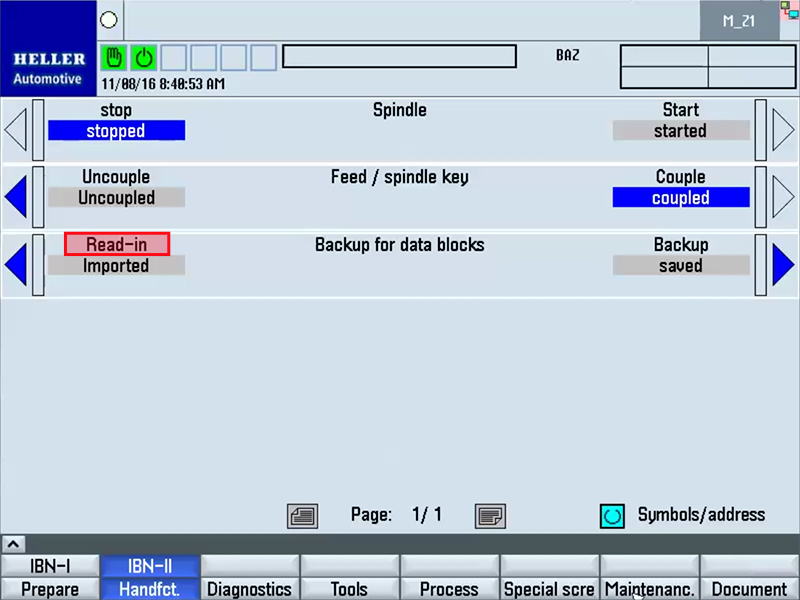

Backup

Read-In

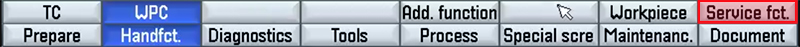

Call Up Service FunctionsPreconditions:

Press lower horizontal softkey "Man.funct.".

HMI screens are available for the following machine components:

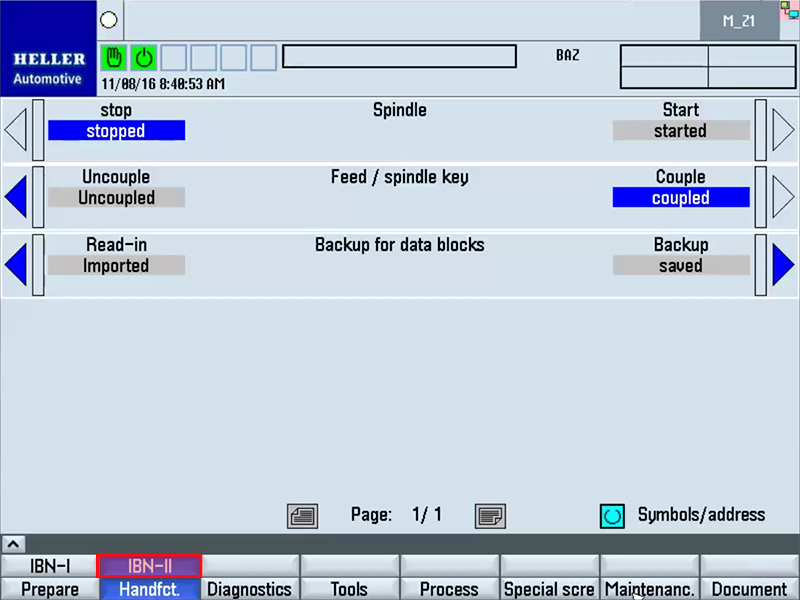

Fundamental PrinciplesThe "Brake active axis" HMI function of the "IBM I" HMI screen is

used to release the motor brake of an NC axis in case of malfunction.

The motor brake holds the NC axis in this situation for safety

reasons.

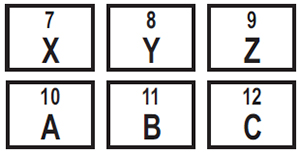

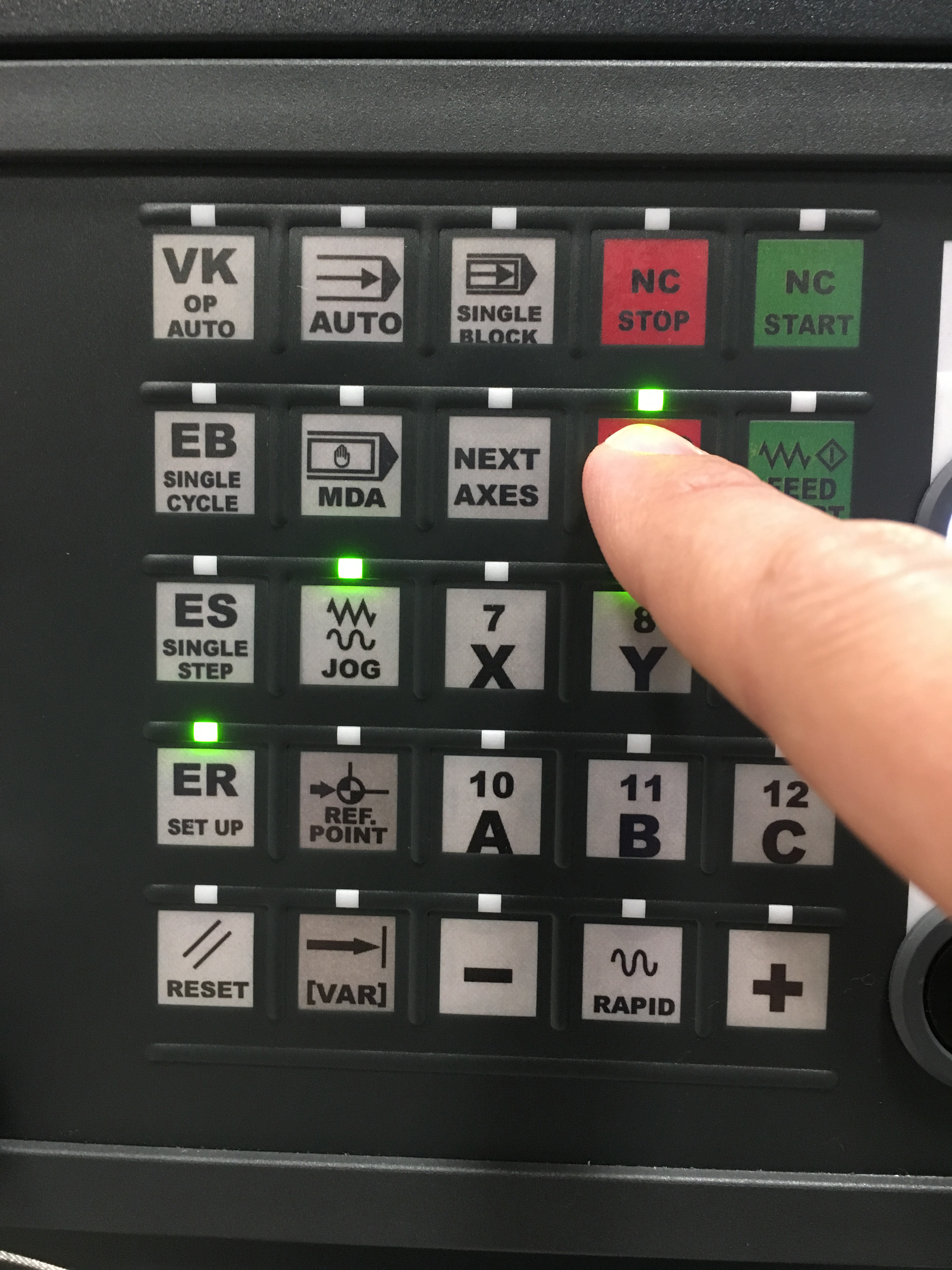

Preselect NC AxisStep 1:Preconditions:

Refer to: "Collision monitoring" Press Machine area key. Step 2:Select axis.

The associated LED is lit. Step 3:Step 4:"SETUP MODE" mode is activated by pressing the middle key SETUP MODE on the machine function operator panel. Provided that the green "Electronic Key" has been inserted into the EKS holder. Release Motor BrakeStep 1:Press the "IBN-I" softkey.

Step 2:In addition to the "Brake active axis" function, press and hold the Approval

key on the main operator panel while performing the brake unclamp procedure. Step 3:Press left-hand softkey assigned to the line "Brake active axis" and

hold it down. |