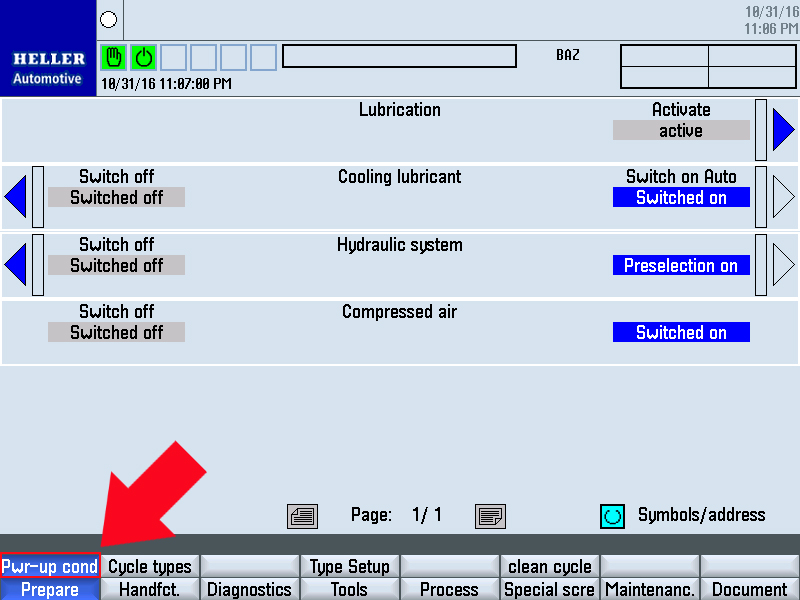

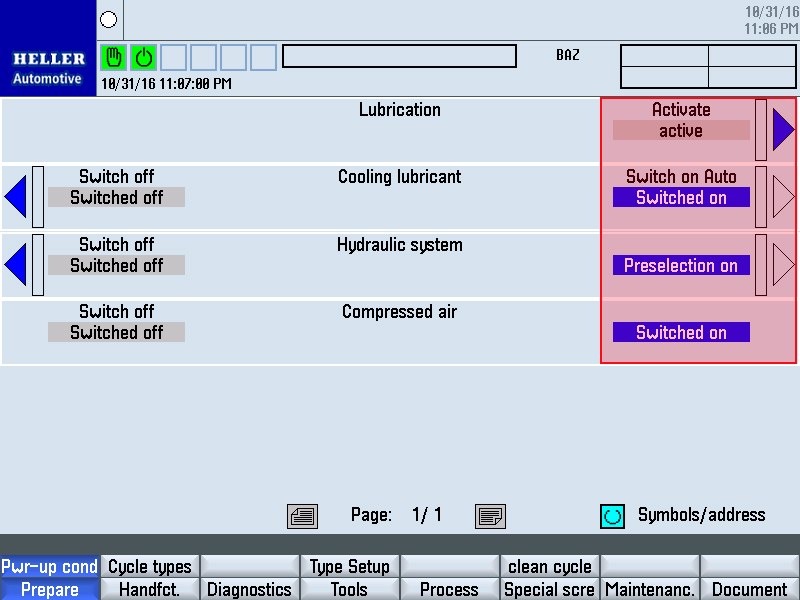

Preparing the MachinePower-up conditionsFor automatic production operation, all media, the chip conveyor etc.

must be switched on. Step 1:Preconditions:

Press upper horizontal softkey "Pow-up condition"

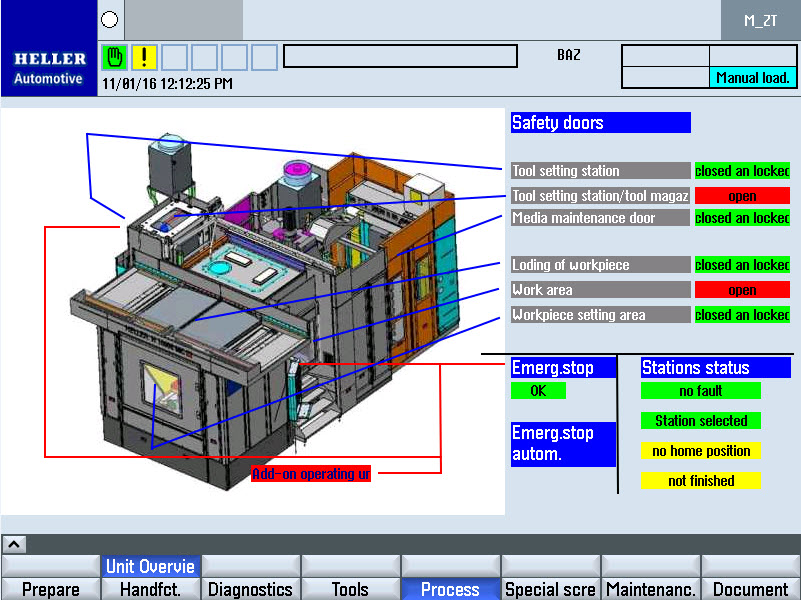

Step 2:Opening the HMI menu "Process"Step 1:With Data menu key call up the basic menu on the main operator

panel.

Station OverviewStep 1:Preconditions:

Press upper horizontal softkey "Stat. overview".

Emergency stop

Station status

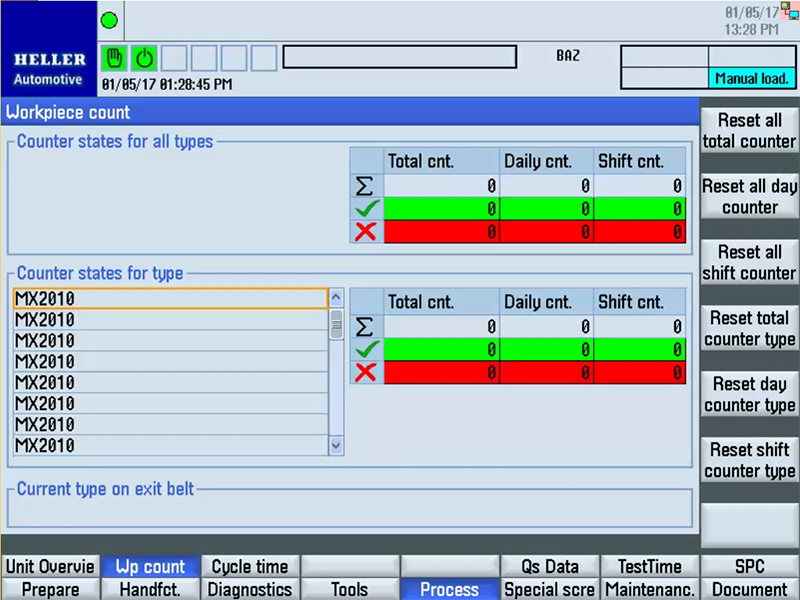

Workpiece CounterThe "Workpiece counter" HMI screen shows the workpiece counter readings of the current workpiece type in the unload area. Three counters simultaneously run in parallel for the workpiece to be produced which are displayed in the following fields:

Step 1:Preconditions:

Press upper horizontal softkey "Wp Counter".

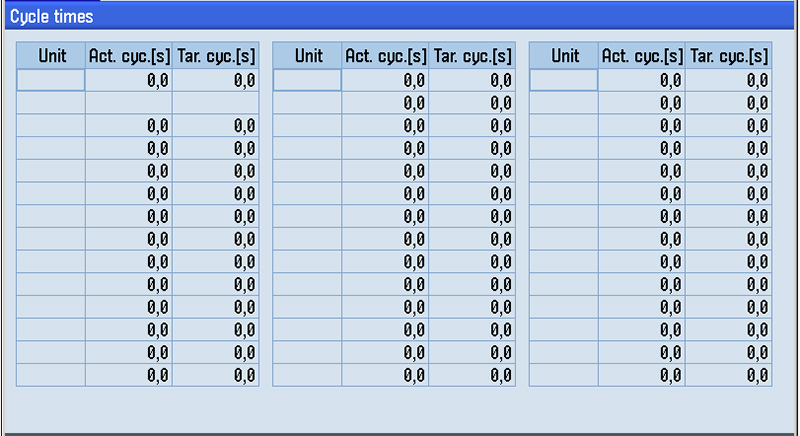

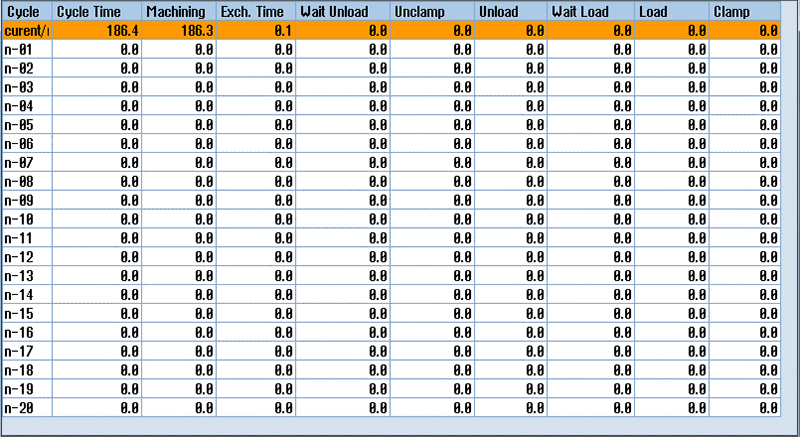

Total counter Type-related counter Resetting the counters Cycle timeThe "Cycle time" HMI screen displays the actual and target cycle times for the module. Cycle times are displayed in seconds and to one decimal place. Step 1:Preconditions:

Press upper horizontal softkey "Cycle time". Actual cycle Reference cycle Data Matrix CodeStep 1:The "DMC" HMI screen, which can be selected via the "Qs Data"

softkey, allows the Data Matrix Code of the workpiece to be

displayed.

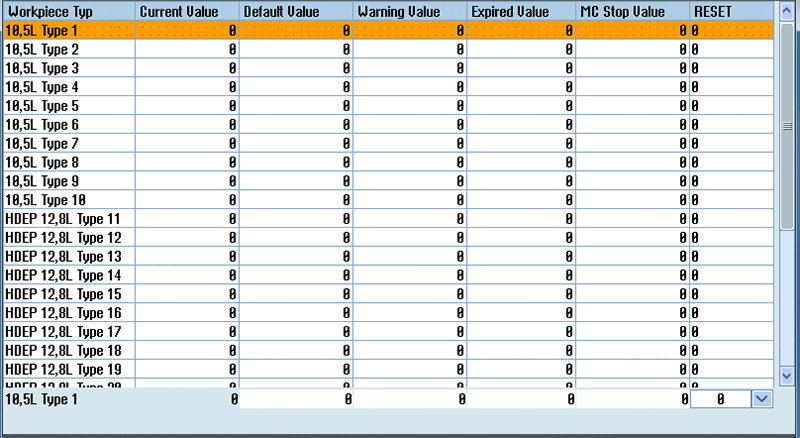

Test timeStep 1:SPC PartsStep 1:The "SPC" screen enables you to specify, for each workpiece type, the number of workpieces after which a "measuring component" is to be transported to the SPC location of the machine. The component concerned is then unloaded after machining. Current Value Warning Value Expired Value / MC Stop Value |