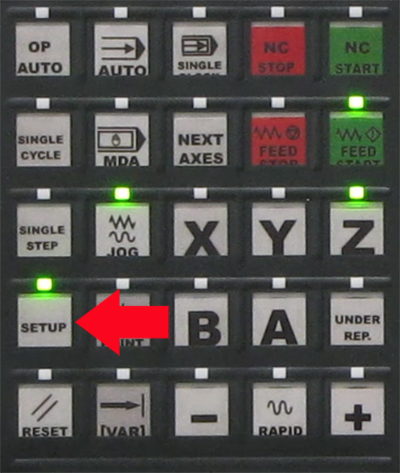

Pressing the Setup key removes the station from the system

interlinkage. "Setup" mode is activated.

"Setup" mode can be used to trigger individual movements, even

when the safety door is open. Select the required movement from

the HMI screens of the "Manual functions" area.

B

The left and/or right vertical softkeys of the corresponding screen

line are used to trigger the individual movements. (With the HT8, the

two softkeys are arranged to the right of the screen).

Initial situation:

After the controller has run up, the affected machine (unit) will initially

be in "Setup" mode. NC modes "JOG" and "REF" are also effective.

Effect of "Setup" mode on other functions:

- NC modes "MDA" and "AUTO" can be selected.

- Single Block can be selected.

The following preconditions must be met before setup mode can be

activated:

- Movement with safety door closed:

- Preselection Open Safety Door switch in "Automatic" position.

- Movement with open safety door:

- Specific access rights granted by password.

- Preselection Open Safety Door switch in "Setup" position.

With the HT8, machine operating modes are selected via

touchscreen fields. The touchscreen fields can be called up with the

U (User) key.

Automatic

Use the key to change to "Automatic" NC mode, also frequently

known as "AUTO".

The "Automatic" NC mode is used for the fully automatic execution

of part programs. In this operating mode, part programs are selected,

started, corrected, selectively influenced (for example in "Single

block") and executed.

MDA

Use the key to change to the "MDA" operating mode, also known as

"MDI (Manual Data Input)".

This operating mode enables you to control the machine by

processing an NC block or a sequence of NC blocks. The NC blocks are entered into the "MDA program" sub-window of the MDA basic

screen.

Part programs can be created and processed block by block here,

in order to then store the tested NC blocks in part programs. With

"Teach In", movement sequences can be incorporated into the MDA

program by approaching and storing of positions.

JOG

Use the key to change to the "JOG" NC operating mode, also known

as Jogging, Setup mode or Inching mode.

Conventional movement of the machine by:

- Continuous movement of the axes using Direction keys.

- Incremental movement of the axes using Direction keys.

- The handwheel.

The "JOG" NC mode is used for manual movement mode and for

setting up the machine. For settings there are the machine functions

referencing, repositioning, handwheel or movement in specified

incremental dimensions and redefinition of control zero point

(preset).

In NC-mode "JOG", no automatic pallet transport takes place.

Ref Point

The machine function "Referencing" is called up with REF.

The NC mode JOG is essential here.

Inc Var

With the INC function (incremental dimension), the preselected axis

is moved in fixed increments in the appropriate direction in manual

mode whenever a direction key is pressed.

Incremental Feed Variable.

Incremental movement with variable increment width.

The adjustable value for the variable increment is preset in the menu

"Machine" in NC mode JOG using the softkey "Inc".