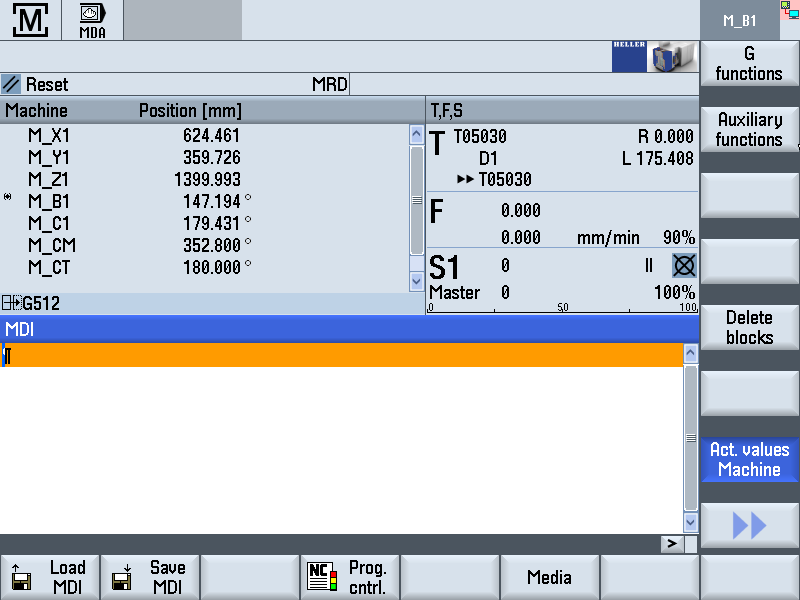

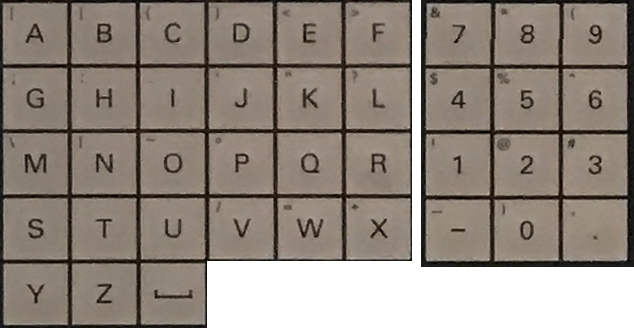

Functions in MDA ModeBasic functions with MDAIn "MDA" (Manual Data Automatic) NC mode, part programs are on the one hand produced and processed block-by-block. On the other, already prepared MDA programs are called up and processed. To do so, the co-ordinates of the travel positions and the additional functions (preparatory conditions, auxiliary functions ...) are entered in the "MDA program" window. The control processes the entered blocks after actuation of the NC start key. Step 1:Preconditions:

Press the Setup key. Step 2:Change to "MDA" NC mode with MDA. Step 3:Call up MDA program

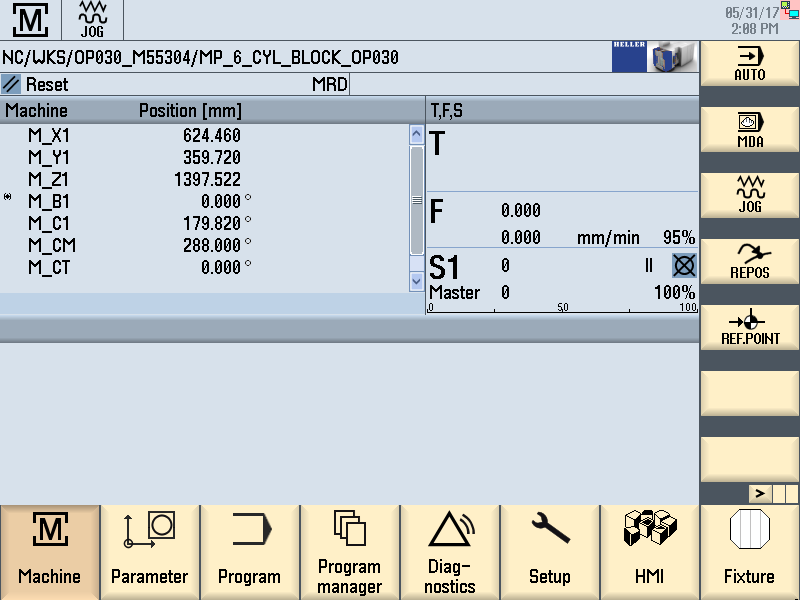

Information on how to avoid collision can be found in Section: "Machine axis movements in manual mode" Step 1:The general "Preconditions for machine functions" are satisfied. Step 2:If necessary press softkey to "Delete MDA buffer". Step 3:Select the desired MDA program (MPF) using the Cursor keys. Step 4:At the HMI, press the "NC Start" key. Approaching an axis positionAn example of axis positioning is "rapid motion X axis to mid table position". With effective zero offset (G54...), the axis positions relate to the workpiece zero point. With preparatory condition G53, the effectiveness of the zero offset is cancelled and the path information relates to the fixed-value machine zero point. Step 1:The "MDA" NC operating mode is selected from the "Machine" main

menu. Step 2:

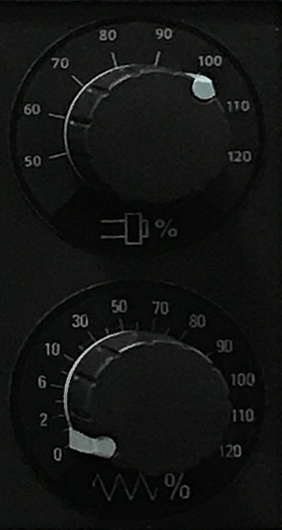

Enter NC block "G0 G53 X0" into the "MDA program" window. Step 3:Step 4:Issue the feed enable using Feed start.

"Feed Start" lamp lights up. This section refers to Pallet Changer model only. Step 1:The general "Preconditions for machine functions" are satisfied. Step 2:If necessary press softkey to "Delete MDA buffer". Step 3:Select the desired MDA program (MPF) using the Cursor keys. Step 4:At the HMI, press the "NC Start" key. |